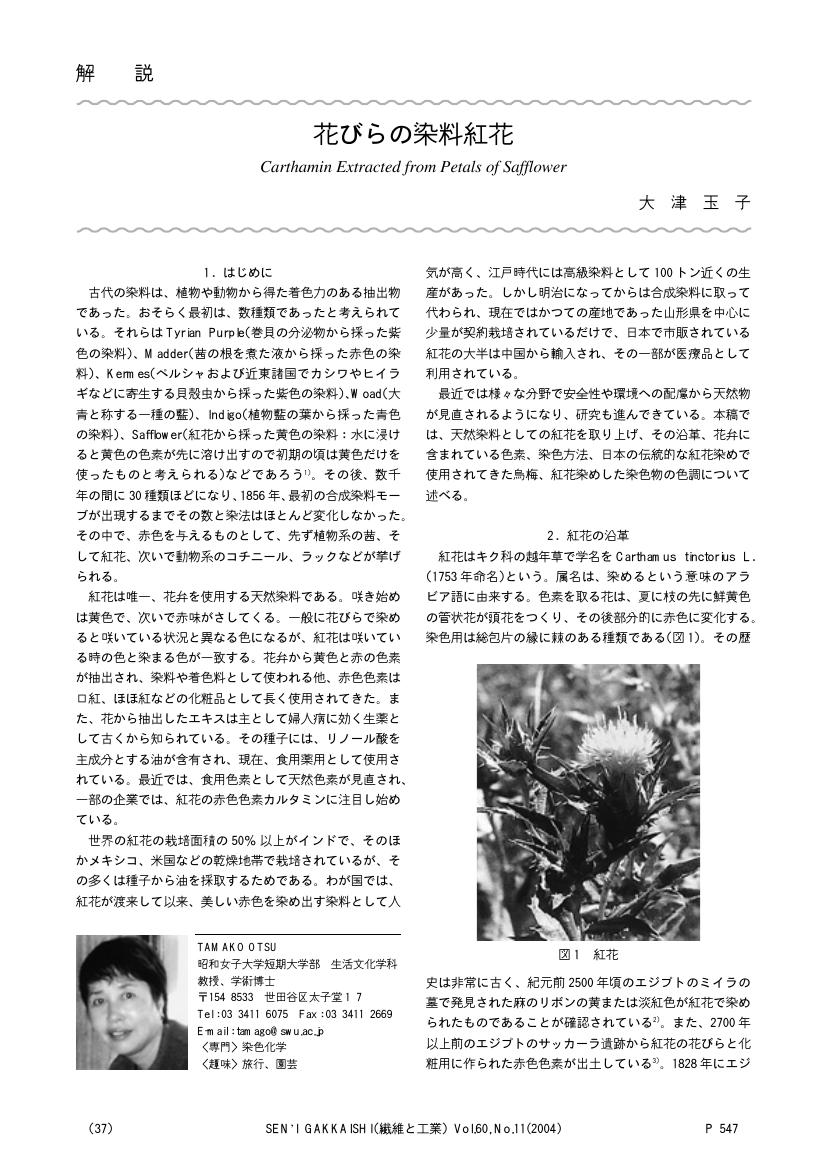

6 0 0 0 OA 花びらの染料紅花

- 著者

- 大津 玉子

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.60, no.11, pp.P_547-P_552, 2004 (Released:2005-12-15)

5 0 0 0 OA プラスチック材料の耐候性

- 著者

- 野中 矩仁

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.40, no.7, pp.P493-P503, 1984-07-10 (Released:2008-11-28)

- 参考文献数

- 23

- 被引用文献数

- 1 1

5 0 0 0 OA 竹繊維の特徴とその用途開発

- 著者

- 池田 善光

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.65, no.1, pp.P_45-P_48, 2009-01-10 (Released:2009-02-10)

5 0 0 0 OA 開繊技術と新しいコンポジット材料への応用

4 0 0 0 OA 水着の変遷と未来

- 著者

- 永島 和祥

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.62, no.1, pp.P_25-P_28, 2006 (Released:2006-04-01)

4 0 0 0 OA 久留米絣の歴史

- 著者

- 中村 健一

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.61, no.6, pp.P_152-P_156, 2005 (Released:2006-02-17)

4 0 0 0 OA 布の乾燥速度について

- 著者

- 山田 晶子

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.41, no.6, pp.T248-T254, 1985-06-10 (Released:2008-11-28)

- 参考文献数

- 9

In order to understand the drying process of fabrics, drying experiment in household manner was conducted at five atomospheric conditions. (10 and 20°C at 65% RH, and 30°C at 40, 65 and 90% RH)Other experiments on 18 samples of different fabrics were conducted in a condition of 30°C at 40% RH.The following conclusions were obtained.1. Evaporation rate of water (K1 [g/cm2•min]) in the constant rate period is mainly determined by the difference between the temperatures of air and wet bulb (ta and tw), although it changes somewhat by the difference between fabrics.In the constant rate period, the water in the fabric comes to the surface so rapidly by capillary migration, that the fabric surface is almost saturated with water vapor, and evaporation of water continues in each constant rate of each fabrics.Hygroscopic, roughly wovened, napped fabric has a wide surface for evaporation, and water evaporates rapidly from these fabrics than from other hydrohobic smooth surfaced fabrics in the constant rate period.2. The end of the constant rate period where the critical moisture content (C. M. C.) is defined, appeared to be the final point where the fabric surface is still saturated with water vapor.Higher rate of water transfer from the fabric to the air in the constant rate period, and slower capillary migration in the fabric are main factors for higher C. M. C.3. The drying rate constant (K2 [1/min]) in the falling rate period is greater for hydrohobic fabrics, and for thinner fabrics. Also, for hygroscopic fabrics with smaller volume fraction of fiber, the rate constant K2 is greater.

4 0 0 0 OA タイヤに求められる繊維材料

- 著者

- 稲田 則夫

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.64, no.9, pp.P_283-P_286, 2008-09-10 (Released:2008-10-10)

4 0 0 0 OA セルロースの光崩壊に関する研究

- 著者

- 鯨井 忠五

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.22, no.2, pp.84-89, 1966-02-10 (Released:2008-11-28)

- 参考文献数

- 33

- 被引用文献数

- 1 2

Reaction mechanisms of photodegradation of cellulose have been proposed under consideration of the experimental facts obtained in report (1) to (VI). The degradation mechanisms are different according to wavelength of light used in irradiation experiments, i.e., (1) on irradiation by λ 1850A, the photochemically primary dissociation occurs in cellulose by its strong absorption of light of this wavelength, the reaction being independent of the presence of oxygen. At the comparatively early period of exposure, direct scission of glucosidic linkage predominates but on prolonged exposure, the formation of 2, 3- dialdehyde by splitting off H-atoms from secondary carbon atoms of the molecule occurs, the latter being easily degradated by alkali medium such as cuam solution. (2) On the other hand, coexistence of oxygen is indispensable to the photodegradation by λ 2537 A irradiation. In this case, absorption matter of λ 2537A is oxygen molecule (Herzberg band), because cellulose is transparent against visible and ultraviolet light having a wavelength longer than λ 2000 A. The main initial step of this reaction is as follows: the excited oxygen molecule thus formed abstracts a hydrogen atom from 1-carbon atom of pyranose ring to form cellulose radical and this reacts with oxygen and other cellulose molecule to produce cellulose peroxide as can be seen in the case of autoxidation of ordinary hydrocarbons. This peroxide is then decomposed photochemically and at the same time, the chain is broken into two chain fragments, accompanying the formation of δ-lactone as the end group of one fragment. The end group of the other fragment has the same configuration as ordinary cellulose molecule. The lactone end group is further hydrolyzed photochemically under the trace of water to form hydroxy-carboxilic acid end group.The quantum yields of each wavelength are calculated and the following values are obtained: γ (1850A)=1×10-2, γ(2537A)=0.5×10-2. Both values are far smaller than unity. The cause of these small values may be attributed mainly to the cristalinity of cellulose fine structure, i.e., in the case of λ 1850A irradiation, recombination of two dissociated chain fragments occurs in crystal region according to Franck-Rabinowitch theory, while in the case of λ 2537A irradiation, diffusion of oxygen molecule, necessary for photoxidation, into this region are difficult and in consequence, photoxidative degradation is inhibited. In both cases, role of crystal region reduces the quantum yield.

4 0 0 0 OA 衣料サイズの変遷と新JIS規格の概要

- 著者

- 三吉 満智子

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.54, no.4, pp.P109-P115, 1998-04-10 (Released:2008-06-30)

- 参考文献数

- 8

4 0 0 0 OA 布の紫外線防御に与える染色の効果

- 著者

- 塩原 みゆき 齊藤 昌子 佐々木 政子 竹下 秀

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.65, no.9, pp.229-235, 2009-09-10 (Released:2009-10-10)

- 被引用文献数

- 1 1

The ultraviolet radiation (UV) protection efficiency of apparel dyed fabrics of cotton and polyester were evaluated by UPF (UV-B protection index) and APE (UV-A protection index) to investigate the effects of hue and lightness of the fabrics. UV transmittance of fabrics changed along with the thickness of the fabrics. The characteristic spectral transmittance of dyes appeared on the dyed taffeta (thickness: 0.1 mm), but on the dyed fabrics thicker than kanakin (thickness: 0.3 mm) they were less than 10% in all UV region. White fabrics having not enough UV protection efficiency increased their UPF and APE by dyeing and showed good protection efficiency. If the L* values of dyed fabrics were same, UPF is higher in the order of yellow, red, blue and black color. The required conditions for taffeta, thinnest fabric in this research to have enough UV protection efficiency are as follows: L* values of cellulose should be less than 25 regardless of their hue, L* values of polyester should be less than 86 in yellow, less than 67 in red and blue, less than 60 in black color, and addition to those transmittance at 370 nm should be less than 10%.

4 0 0 0 OA 間葉系幹細胞を用いた骨と歯周組織の再生

- 著者

- 辻 紘一郎

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.61, no.6, pp.P_150-P_151, 2005 (Released:2006-02-17)

4 0 0 0 OA 心地よい触感の追求:布の「しっとり感」、「ぬめり感」

4 0 0 0 ビザンティン錦の伝播の道をさぐる

- 著者

- 山中 良子

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.68, no.6, pp.P-162-P-166, 2012 (Released:2012-08-09)

4 0 0 0 OA 世代別「ロリータファッション」考察

- 著者

- 加藤 訓仁子

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.66, no.7, pp.P_219-P_222, 2010-07-10 (Released:2010-08-17)

3 0 0 0 OA 万葉の染め

- 著者

- 三石 賢

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.50, no.10, pp.P580-P581, 1994-10-10 (Released:2008-11-28)

3 0 0 0 OA 藕絲-ミャンマ・インダ族の藕絲織と当麻曼荼羅縁起絵巻

3 0 0 0 OA プラスチック光ファイバ(POF)と車載用POFケーブルに要求される性能

3 0 0 0 OA 防護服素材の開発動向

- 著者

- 金 翼水 Yoon Kee Jong 洪 京我

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.66, no.3, pp.P_106-P_113, 2010-03-10 (Released:2010-04-10)

- 被引用文献数

- 1 1

3 0 0 0 OA アルギン酸類の概要と応用

- 著者

- 宮島 千尋

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.65, no.12, pp.P_444-P_448, 2009 (Released:2010-02-02)

- 被引用文献数

- 3