2 0 0 0 OA タングステンの金屬論(承前)

- 著者

- K.O.

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.4, no.12, pp.1301-1315, 1918-12-25 (Released:2009-07-09)

- 著者

- Jin Jia Shang-lei Yang Wei-yuan Ni Jian-ying Bai Yang-shenglan Lin

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.55, no.1, pp.338-338, 2015 (Released:2015-02-06)

2 0 0 0 OA 鉄及び鉄合金の高温酸化に関する研究

- 著者

- 三島 徳七 椙山 正孝

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.30, no.8-9, pp.233-234, 1946-01-25 (Released:2009-07-09)

2 0 0 0 OA 耐熱鋼・耐熱合金の現状と将来の展望

- 著者

- 依田 連平

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.65, no.7, pp.725-746, 1979-06-01 (Released:2010-02-22)

- 参考文献数

- 282

2 0 0 0 OA 安定オーステナイト系ステンレス鋼の加工硬化と変形組織に及ぼす炭素および窒素の影響

- 著者

- 吉武 睦海 土山 聡宏 高木 節雄

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.98, no.6, pp.223-228, 2012 (Released:2012-05-31)

- 参考文献数

- 17

- 被引用文献数

- 3 22

Stable austenitic stainless steels containing 0.1 % carbon and nitrogen (Fe-18%Cr-12%Ni-0.1%C and Fe-18%Cr-12%Ni-0.1%N alloys) were tensile-tested to clarify the difference between the effects of carbon and nitrogen on the work hardening behavior as well as the deformation microstructure development in austenite. The carbon-added steel exhibited a much larger work hardening rate than the nitrogen-added steel in the high strain region (true strain > 0.25) although the dislocation accumulation was more significant in the nitrogen-added steel. EBSD analysis revealed that deformation twins were more frequently formed in the carbon-added steel, which leads to the TWIP effect. The reason why the nitrogen-added steel showed the less twinning behavior seemed to be mainly related with the short range order (SRO) composed of Cr and N atoms.

2 0 0 0 OA 水素還元した鉄鉱石の細孔分布

- 著者

- 近藤 真一 原 行明 須賀田 正泰 土屋 勝

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.53, no.7, pp.724-726, 1967-06-01 (Released:2010-10-12)

- 参考文献数

- 4

- 被引用文献数

- 2 2

1 0 0 0 OA フェライト–パーライト複合組織鋼における降伏点現象のマルチスケール有限要素解析

- 著者

- 柳川 真之裕 渡邊 育夢

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2023-080, (Released:2023-10-19)

- 参考文献数

- 21

Yield-point phenomena in Ferrite–Pearlite duplex steels were investigated using multi-scale computational simulations. In this multi-scale simulations, stress–strain relationship of Ferrite phase was characterized by an elastoplastic constitutive model considering yield-drop behavior and its material constants were determined by minimizing residual error between a computational simulation and experiment of tensile test, where yield-point phenomenon in a tensile test of Ferrite steel was reproduced.Using the determined material response of Ferrite phase, finite element analyses of Ferrite–Pearlite duplex microstructure were performed to examine its macroscopic material response and its microscopic deformation mechanism. Besides, finite element analyses of tensile test based on the numerical results of microscopic finite element analysis were conducted to reproduce yield-point phenomena in Ferrite–Pearlite duplex steels.

1 0 0 0 OA 流動層を用いた使用済みプラスチックガス化プロセスの開発

- 著者

- 百野 浩一 石井 純 細原 聖司 木島 秀夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.109, no.9, pp.728-737, 2023-09-01 (Released:2023-08-31)

- 参考文献数

- 29

Used plastic waste flowing into ocean has become a worldwide problem. In recent years international trade in used waste plastics has been regulated. Therefore, a large amount of used plastic should be disposed domestically. On the other hand, used waste plastics with high calorific value could be used as an energy source. Then a gasification process of used plastics using fluidized bed has been newly developed. In this process, used plastics were decomposed in a fluidized bed reactor at around 600°C which was lower temperature than that used in current commercial processes. Higher calorific value gas could be attained by a gasification reaction control at the lower temperature. Hydrogen enriched gas generated from the water gas shift reaction of the basic oxygen furnace gas was used as fluidizing, or gasifying agent since hydrogen was considered to have an effect for promoting the decomposition reaction of hydrocarbon in used plastics. As fluid medium in the reactor, catalysts were used to improve gasification efficiency. In this study, the effect of gasification temperature and the type of the catalyst on a calorific value of produced gas and a gasification efficiency were investigated. High calorific value gas (LHV: 5000 kcal/Nm3) could be successfully produced from pyrolysis of used plastics by appropriate gasification temperature and catalyst.

1 0 0 0 OA 先進的画像処理による組織検出

- 著者

- 田口 茂樹 弘川 奨悟 安田 格 徳田 耕平 足立 吉隆

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.103, no.3, pp.142-148, 2017 (Released:2017-02-28)

- 参考文献数

- 8

- 被引用文献数

- 9 6

Two kinds of advanced image processing were applied to multi-phase microstructures. One is evolutional image processing where optimized filter set was suggested by genetic programing. Another is trainable WEKA segmentation where features are extracted by many kinds of filters, followed by machine learning for classification. Once an optimized filter set is determined, efficiency of image processing for new data set is improved remarkably in comparison with a case of manual image processing.

1 0 0 0 OA 中炭素鋼の低温線形摩擦攪拌接合

- 著者

- 青木 祥宏 黒岩 良祐 藤井 英俊 村山 元 泰山 正則

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.103, no.7, pp.422-428, 2017 (Released:2017-06-30)

- 参考文献数

- 32

- 被引用文献数

- 17 11

Linear Friction Welding (LFW) is a solid-state joining process, in which a joint is obtained through the relative motion of two components under a high contact load. The most important factor of this conventional method is to obtain a fresh surface at the interface by expelling the weld interface as flash. In this study, medium carbon steel was welded by LFW at a low frequency, low amplitude and high applied pressure. As a result of the temperature measurements and microstructure observations, the maximum temperature of the weld plane was confirmed to be below the A1 transformation temperature, and martensitic transformation was prohibited at the weld interface. The key concept of this method are applying a large strain deformation to the interfaces to recrystallize at a lower temperature which is different from the conventional LFW.

1 0 0 0 OA 製鋼スラグ非晶質相の淡水への溶出挙動に及ぼす有機酸錯体生成の影響

- 著者

- 川﨑 大輝 松浦 宏行

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.107, no.1, pp.92-102, 2021 (Released:2020-12-31)

- 参考文献数

- 41

- 被引用文献数

- 3 4

To recover the barren coast or degraded paddy field, the supply of nutrient elements such as Fe is effective. Since steelmaking slag contains various kinds of potent elements, it is expected to be used as an environmental restoration material. The dissolution mechanism of various elements from slag and the influence of surrounding organic matters and microorganisms must be clarified to utilize steelmaking slag in these methods effectively. In this research, the dissolution tests were conducted by using synthesized CaO-SiO2-FeO-Al2O3-P2O5 amorphous slag samples and aqueous solutions containing gluconic acid. Concentration of various elements in the solution, especially Fe, increased by the addition of gluconic acid. To evaluate the effect of gluconic acid on the dissolution behavior quantitatively, the existence forms of various elements in the solution were thermodynamically estimated based on the experimental results. The maximum ratio of chelated iron to total iron was 97%, indicating that the increase in iron concentration by adding gluconic acid was owing to the formation of iron complex ions. On the contrary, concentrations of Ca, showing complex formation ratio low, or Si and P, for which the complex formation has not been reported, also increased by adding the acid. This suggested the existence of elution mechanisms other than complex formation.

1 0 0 0 OA 超音波印加された固液混相領域の液相流動

- 著者

- 岩井 一彦 真野 義丈

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.8, pp.778-784, 2019 (Released:2019-07-31)

- 参考文献数

- 11

Flow excitation in a solid-liquid mixed region surrounded by a solid layer is not easy because of difficulty of direct exertion of force on the liquid and large apparent viscosity. Ultrasound is expected as a flow excitation tool in the solid-liquid mixed region because it can transmit force from the outside of the surrounding solid layer. Thus, investigation on the liquid motion under the ultrasound imposition on the solid-liquid mixed region has been done in this study. Because of the large difference of acoustic impedance between an alumina and a polyacetal, they were chosen as the solid particles in the solid-liquid mixed region while water was chosen as the liquid. The superficial velocity in the solid-liquid mixed region increased as its length became shorter under the condition that the voltage on the ultrasound vibrator was constant. Apparent porosity under the imposition of the ultrasound was larger than the real porosity evaluated without the ultrasound when the water-alumina system was used, and the former increased as the solid-liquid mixed region length became shorter. On the other hand, the apparent porosity under the ultrasound imposition was only slightly larger than the real porosity without the ultrasound imposition in the case of the water-polyacetal system. The difference between these systems might be caused by the acoustic impedance difference between the alumina and the polyacetal.

1 0 0 0 OA たたら製鉄の銑生成に及ぼす砂鉄中TiO2濃度の影響

- 著者

- 久保 善博

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.109, no.1, pp.25-32, 2023 (Released:2022-12-31)

- 参考文献数

- 13

The aim of this project was to learn roles of titanium oxide (TiO2), an impurity contained in iron sand, in the products resulting from traditional iron making processes, tatara operations. For this purpose, iron sand was collected using two different mineral processing methods from four different locations in the Chugoku area of Japan, and these samples were used to run small-scale tatara experiments. Iron sand collected with traditional gravity separation method contained 8 to 12% TiO2, while iron sand collected with modern magnetic separation method contained less than 5% TiO2. When gravity-separated iron sand was used in a tatara under strong reducing conditions, zuku (cast iron) flowed out of the tatara. In contrast, magnetically collected iron sand failed to produce zuku, but did produce raw steel at the bottom of the furnace. Further, even magnetically isolated iron sand could produce zuku when it was supplemented with ilmenite, a titanium-iron oxide containing mineral. The results show that TiO2 plays a key role in producing cast iron in tatara operations, and the fact that Akome iron sand is known to produce cast iron as it contains higher levels of TiO2. In contrast, Masa iron sand which is known to produce steel (tamahagane) contains much less TiO2 and hence is not suitable to produce cast iron. These observations agree with historical descriptions stating that pre-modern tatara operators knew to add iron sand from a specific locality (which is rich in TiO2) to Masa-type iron sand to produce cast iron.

1 0 0 0 OA 高リン鉄鉱石からの直接脱リン

- 著者

- 雀部 実 飯田 佳未 横尾 友美

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.2, pp.325-330, 2014 (Released:2014-01-31)

- 参考文献数

- 9

- 被引用文献数

- 7 7

Iron ore containing higher concentration of phosphorus is reduced by hydrogen gas containing water vapor. 13% of removing yield of phosphorus is obtained. It is observed that removing rate of phosphorus can be expressed as apparent 1st order reaction equation. The reaction rate equation is divided into two parts. Rate constant of the former reaction is about 10 time larger than that of the latter equation. It is estimated on the basis of a previous research result that phosphorus removed from iron oxide is gaseous phosphorus and form of remained phosphorus is Fe2P.

1 0 0 0 OA 雑録

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.41, no.1, pp.67-75, 1955-01-01 (Released:2009-07-09)

1 0 0 0 OA 随想 研究開発と寓話

- 著者

- 長島 晋一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.62, no.7, pp.787-788, 1976-06-01 (Released:2010-02-22)

1 0 0 0 OA コークス強度制御の高度化に向けた石炭利用技術

- 著者

- 有馬 孝 愛澤 禎典 野村 誠治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.2, pp.110-117, 2014 (Released:2014-01-31)

- 参考文献数

- 58

- 被引用文献数

- 3 5

Coking coal necessary for cokemaking process is exhausted in progress; increasing the ratio of non- or slightly-coking coal is required. However, non-or-slightly coking coal causes a lot of structural defects in the coke lump and decreases coke strength because of its low dilatation and high shrinkage.For increasing the ratio of non- or slightly-coking coal, pre-treatment technology of coal such as the coal size control, increasing the coal bulk density and the rapid preheating reforming etc. have been developed and a new cokemaking process SCOPE21 that consists of those technologies have already started and high quality of coke is produced using over 50% of non- or slightly-coking coal. In addition, knowledge of coke structure formation mechanism and degradation mechanism of coke were remarkably developed.This paper reviews the past research on coal utilization technologies, carbonization mechanism and coke structure and degradation behavior of coke, and describes future direction of research and development for increasing the ratio of non- or slightly-coking coal.

1 0 0 0 OA 鉄鋼業におけるプロセス自動化のための新しい計測技術

- 著者

- 伊勢居 良仁

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.106, no.9, pp.591-601, 2020 (Released:2020-08-31)

- 参考文献数

- 58

- 被引用文献数

- 1

The instrumentation technology for process automation in the steel industry has been evolving with the demands of the times, adapting to its production process and its harsh environment as the latest measurement techniques applied by considering the physical measurement principles. Today, the instrumentation technology has become one of the essential technologies to maintain the competitiveness in the steel industry. In this review, the recent development trends and future prospects are described based on lectures and papers on process instrumentation technology published by the Iron and Steel Institute of Japan (ISIJ) in the last decade. The main challenges in recent steel processes were reducing greenhouse gas emissions, supplying high-quality products represented by high-strength steel sheets, and keeping stable operation without skilled workers. To meet these challenges, new measurement techniques that had been advanced in recent years, such as radio waves sensing, image processing, optical fiber sensors, and multivariate analysis, had been applied. The newly obtained process information contributes to further sophisticated processes automation, and is applied to Artificial Intelligence (AI) and Cyber-Physical Systems (CPS). In the next decade, it is hoped that the instrumentation technology will continue to make progress toward the establishment of a sustainable steel industry.

1 0 0 0 OA リン濃縮スラグからのリンの分離

- 著者

- 岩間 崇之 井上 亮 中瀬 憲治 植田 滋

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.109, no.1, pp.1-12, 2023 (Released:2022-12-31)

- 参考文献数

- 31

- 被引用文献数

- 4

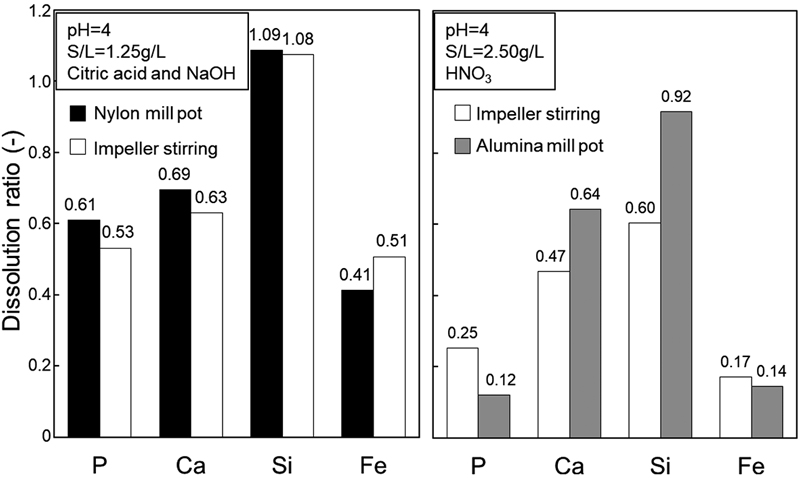

Since 10 million tons of steelmaking slag, which contains a few percent of phosphorus, are annually produced, the phosphorus amount in the slag is equivalent to the annual import volume of phosphorus rock in Japan. Therefore, the steelmaking slag is attracting attention as a potential phosphorus resources. Phosphorus-concentrated slag obtained by the dephosphorization reaction between high phosphorus hot metal and oxidizing slag at high temperature contains phosphorous comparable to that of phosphorus rock. However, because of high FeO concentration, it is difficult to use for phosphorus resources directly. In this work, the effects of pH, acid type and leaching method on the dissolution behavior of phosphorus from P-concentrated slag were investigated. As a result, phosphorus dissolution progressed at lower pH, and was promoted by the addition of citric acid, which is known as a chelate former. When nylon mill pot stirring with citric acid and alumina mill pot stirring with nitric acid were compared to impeller stirring, respectively. By combining nylon mill pot stirring and citrate leachate, phosphorus dissolution was accelerated, because the slag was pulverized during stirring and a formation of insoluble metal-phosphate was inhibited by the formation of complex ion between leached metal cation and citrate. When the slag was leached with alumina mill pot while controlling pH by nitric acid, the phosphorus dissolution ratio lowered since phosphorus ion and aluminum ion, which is supplied by the dissolution of pot and crushing ball during leaching, constructed secondary products with low solubility along with other dissolved ions.

1 0 0 0 OA 本邦製鉄事業の過去及将来

- 著者

- 野呂 景義

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.2, no.2, pp.159-167, 1916-02-25 (Released:2009-05-26)