- 著者

- 栗林 大樹 佐藤 知広 齋藤 賢一 宅間 正則 高橋 可昌

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.68, no.8, pp.317-323, 2021-08-15 (Released:2021-08-15)

- 参考文献数

- 16

In recent years, materials infomatics (MI), a technology that combines materials engineering and machine learning, has become popular and is used for discovering new materials. In this research, we aimed to verify whether MI can be applied to the problem of “development and maintenance of technology,” which is becoming more difficult due to the decrease in the number of engineers caused by the declining birthrate and aging population in Japan. We selected “discrimination of optical electron microscope images” as the verification target, and used Convolutional Neural Networks (CNNs) as the machine learning technology to discriminate between seven types of sintered metal objects under different sintering conditions, hoping for general applicability to the discrimination problem, and confirmed a discrimination accuracy of 98.5%. In addition, we verified the effectiveness of using pseudo-samples for the discrimination problem using Generative Adversarial Networks (GANs) in the hope of improving accuracy by increasing the number of samples, and confirmed the improvement of accuracy by adding pseudo-samples to the training data.

1 0 0 0 鋳鉄,黒鉛系自己潤滑複合材料の繊維冶金製法

- 著者

- 李 世欽 鈴木 清 中川 威雄

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.35, no.6, pp.552-557, 1988

For further development of the high performance self-lubrication materials being proof against vacuum or high temperature, cast iron fibre composites containing a large amount of graphite were investigated. The cast iron fibre of 20-40 μm in diameter and 1.2 mm in length, which was prepared by chatter-machining a ductile cast iron bar, was mixed with graphite powder and consolidated by compacting in a die, sintering and finally repressing. The optimum conditions for the processing were determined experimentally, and the composite of the almost same mechanical strength as grey iron was made with an addition of 28.8 vol% graphite. In conclusion the fibre metallurgical processing of the high performance self-lubrication composite materials of cast iron and graphite is feasible in the production.

1 0 0 0 連続粉末圧延法による簿板製造の研究

- 著者

- 木村 尚 平林 平八郎 徳吉 睦生

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.10, no.4, pp.172-180, 1963

A continuous method of producing iron strip from powder has been developed. Iron powder directly conversed to green strip by roll compacting, and which was continuously sintered, hot rolled and cooled in hydrogen atmosphere and coiled up. The effects of various continuous powder rolling factors, such as the sintering temperature, roll speed, and hot rolling lood on the properties of hot rolled strip were investigated with Husquvarna Star electrolytic iron powder and Höganäs sponge iron powder.<BR>In general, with increasing the sintering temperature and hot rolling lood the physical and mechanical properties of iron strip by powder rolling were improved, whereas the effect of roll speed was different, depending upon the sinterability of iron powder. These properties obtained were considerably well for the powder metallurgical product, although the sintering time was short. According to the repeated hot rolling or annealing and cold rolling, the pro. perties of the iron strip were equal to those of the conventional iron strip, especially the one made from Husquvarna Star iron powder showed superior magnetic properties.

1 0 0 0 OA 放射光マルチスケールCTで見るセラミックスの3次元内部欠陥構造

- 著者

- 大熊 学 渡辺 修平 篠部 寛 西山 宣正 竹内 晃久 上杉 健太郎 田中 諭 若井 史博

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.66, no.12, pp.604-610, 2019-12-15 (Released:2019-12-15)

- 参考文献数

- 40

The characterization of the processing-induced defects is a significant step for developing defect-free processing, which is important to the assurance of the mechanical reliability of brittle ceramics. Recent advances in multiscale X-ray computed tomography which consists of micro-CT and nano-CT enables us to observe the three-dimensional (3D) internal structure non-destructively. Micro-CT reveals the distribution of defects in the entire body of a sample, while nano-CT reveals the shape of the identified defect. This powerful imaging tool was used to reveal the complicated 3D morphology of defects evolved during sintering of alumina. The hierarchical packing structure of granules was the origin of several types of strength-limiting defects, which could not be eliminated due to the differential sintering of heterogeneous microstructures. This imaging technique of internal defects provides a link between the processing and the fracture strength for the development of structural materials.

1 0 0 0 OA 光機能材料

- 著者

- 宮本 大樹

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.46, no.2, pp.174, 1999-02-15 (Released:2009-05-22)

1 0 0 0 2020年度春季大会研究発表講演募集

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.67, no.1, pp.Mtg1_2-Mtg1_5, 2020

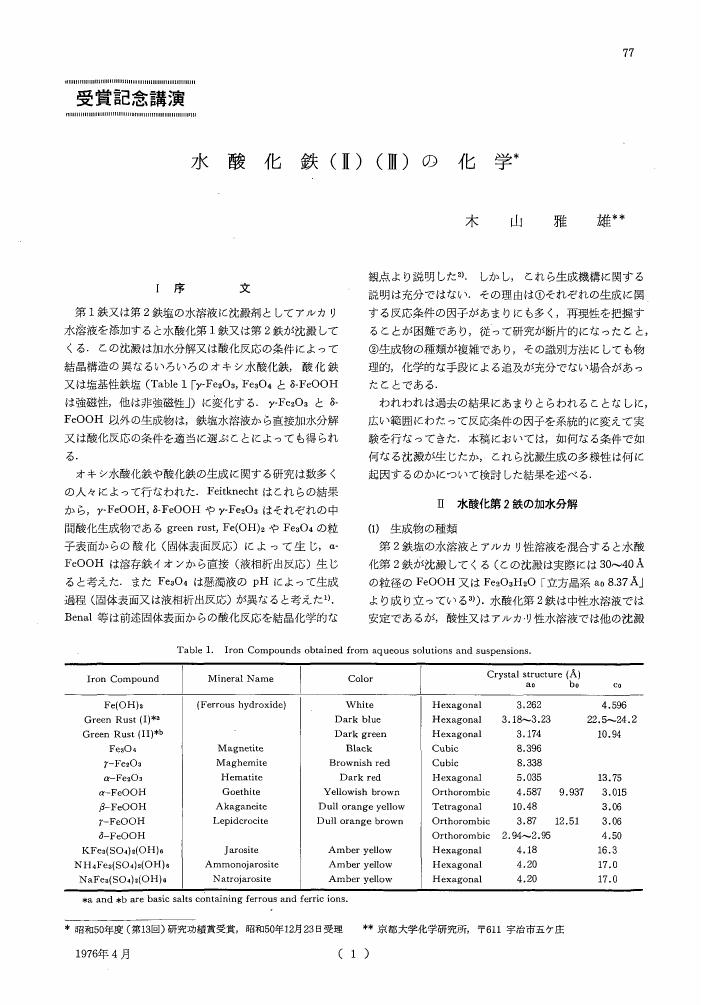

1 0 0 0 OA 水酸化鉄(II)(III)の化学

- 著者

- 木山 雅雄

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.23, no.3, pp.77-84, 1976-04-05 (Released:2009-05-22)

- 参考文献数

- 30

- 被引用文献数

- 29 21

1 0 0 0 OA 熱光起電力用放射率制御セラミックスエミッタ

- 著者

- 渋谷 明信 澁谷 泰蔵 眞子 隆志

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.65, no.6, pp.335-341, 2018-06-15 (Released:2018-06-28)

- 参考文献数

- 27

R3Al5O12 (R: rare-earth) ceramics are one of the emitter candidates for thermophotovoltaic (TPV) systems. We conducted a detailed study on the fabrication, the microstructural characterization, and the thermal emissive performance of porous Yb3Al5O12 (YbAG) emitters. The emitters were synthesized by solid-state reaction and sintered with various conditions using ball-milling powders, which result in different porosities of the samples. Thermal radiation measurements revealed that the porous ceramics had excellent selectivity regarding emission wavelengths and optimal porosity of sintered bodies for emittance wavelengths selectivity are different according to grain size of powders related to sintered body grain size. Generally, in spite of the narrow-band thermal emissions of rare-earth ions, most ceramics do not present sufficient selectivity because of their transparency in the near infrared range. This paper discusses the mechanism of high selectivity from observations of the microstructures of developed YbAG ceramics.

1 0 0 0 錯体重合法を応用した炭素/Fe‐Co合金複合材料の調製と磁気特性

- 著者

- 内田 有紀子 大石 響子 中西 真 藤井 達生 高田 潤 草野 圭弘 菊池 丈幸

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.52, no.8, pp.640-645, 2005

- 被引用文献数

- 2 2

We have successfully prepared Carbon/Fe-Co alloy composites starting from metal organic precursors synthesized by polymerized complex method. The carbon/Fe-Co alloy composites were obtained after the carbonization of the precursors heat-treated at ambient pressure and lower temperatures ranging from 500 to 700°C in N<sub>2</sub> gas flow. Crystalline sizes of both carbon matrix and Fe-Co alloy particles were determined by X-ray diffraction measurements as a function of the Co concentration and the carbonized temperature. The alloy particles were widely dispersed in the carbon matrix and the particle size carbonized at 600°C was about 20∼50 nm observed by scanning electron microscopy. The composite carbonized at 600°C had very small coercivity of 14 Oe and exhibited relatively large permeability spectra at frequency of GHz range.

1 0 0 0 高真空型金属粉末積層造形装置の開発

- 著者

- 萩原 正 堀場 欣紀 佐々 雅祥 中野 禅 清水 透 松崎 邦男 佐藤 直子

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.61, no.5, pp.223-226, 2014

- 被引用文献数

- 2

Aspect Inc. and AIST (National Institute of Advanced Industrial Science and Technology), as a member of ALPROT, which stands for Advanced Laser and Process Technology Research Association, have developed two types of unprecedented Selective Laser Melting platform with a high vacuum built process chamber and a new developed QCW (quasi continuous wave) laser system in the national project, which started from 2010 and conducted by NEDO (New Energy and Industrial Technology Development Organization). In this report, the development status of the Selective Laser Melting platform is mainly introduced.

1 0 0 0 OA 掲載論文の取り消しについて:Fe-Based Glassy Magnetic Cores Prepared by Spark Plasma Sintering Glassy Alloy Powders

- 著者

- Baolong Shen Akihisa Inoue

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.58, no.6, pp.403, 2011 (Released:2011-07-15)

- 被引用文献数

- 1 1

掲載論文の取り消しについて「粉体および粉末冶金」編集委員会, 委員長 吉村 一良「粉体および粉末冶金」Vol.50, No.9に掲載の下記論文1について,先に投稿された下記論文2の内容と著しく重複していることが判明しました.「粉体および粉末冶金」編集委員会では,本件に関し,粉体および粉末冶金投稿規程及び研究倫理上の理由によって,当該論文の掲載を取り消すことにいたしました.この処置は,論文1が論文2の審査中に投稿されたものであり,また論文1中に論文2の引用もなかったため,論文内容の重複について審査段階で認識することができなかったための処置であります.○論文1:Fe-Based Glassy Magnetic Cores Prepared by Spark Plasma Sintering Glassy Alloy Powders, Baolong Shen and Akihisa Inoue,粉体および粉末冶金, Vol.50, No.9 (2003) 680-686. ( Received May 2, 2003 ) ○論文2:Fabrication of large-size Fe-based glassy cores with good soft magnetic properties by spark plasma sintering, Baolong Shen and A. Inoue, Journal of Materials Research, Vol.18, No.9 (2003) 2115-2121. ( Received 27 April, 2003, accepted 10 June, 2003 ).

1 0 0 0 OA レーザーCVD法によるTiO2膜の歯科材料への応用

- 著者

- 桃沢 愛 且井 宏和 伊藤 暁彦 後藤 孝

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.63, no.3, pp.128-131, 2016-03-15 (Released:2016-04-09)

- 参考文献数

- 8

- 被引用文献数

- 2

TiO2 is widely used in dental materials as orthopedic and dental implant thanks to its good properties and biocompatibility. Rutile- and anatase-type TiO2 films were prepared by laser chemical vapor deposition using Nd:YAG laser. The TiO2 films showed cauliflower like microstructures at laser power of 160 W. The highest deposition rate was 17.1 μm/h at the total pressure of 800 Pa. Rutile- and anatase-type TiO2 was formed at the total pressure of 210 Pa, anatase-type at 800 Pa and rutile-type at 1500 Pa. The degree of osseointegration in the early stages is critical for determining the mechanical stability of the implant. The cell attachment behaviors of TiO2 films, in particular, the cell density and aspect ratio of osteoblast cells on TiO2 films were evaluated. Microstructure of the surface and photocatalytic performance of anatase-type TiO2 may be effective for cell attachment.

1 0 0 0 OA 新しい炭素材料: フラーレンの製造と応用の最新動向

- 著者

- 有川 峯幸

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.52, no.2, pp.109-114, 2005 (Released:2006-04-28)

- 参考文献数

- 10

Recently Nano-technology is one of the most popular topics, and Nano Carbon material is said to be the technology that is the nearest to the business. Both Fullerene that is the cage shape carbon molecular, and Carbon Nano Tube that is the tube shape of carbon structure, have already reached to the industrial stage. In this overview, the latest development and information about Fullerene production and application are explained.

- 著者

- 神田 康行 福本 功

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金

- 巻号頁・発行日

- vol.64, no.3, pp.91-99, 2017

<p>Alumite sludge is a precipitation that is generated by anodizing of aluminum sash products. The crystal structure of alumite sludge is changed to α-alumina (α-alumina sludge) by heat treatment. For effective utilization of alumite sludge, we attempted to improve the sintered body mechanical strength by applying milled α-alumina sludge to spark plasma sintering. The raw (no milling) material has a cuboid particle shape. By milling the raw material, the particle shape is changed from cuboid to cube, and the particle size is decreased. The changing particle shapes improved flexural strength to a maximum of 403 MPa at low firing temperatures. Observation of the fracture surface using SEM revealed that the fracture originated from a rectangular pore remaining in the sintered body. The shape factor of the rectangular pore (area, pore ratio, inclination angle) decreased with the change in particle shape. In order to ascertain the experimental result, the effect of rectangular pore shape on crack occurrence was investigated by using finite element method. The principal stress value around the rectangular pore decreased with the change in particle shape. Thus, crack occurrence at the fracture origin is inhibited by the change in particle shape.</p>

1 0 0 0 OA 新しい黒色顔料の開発と化粧品への利用

- 著者

- 鈴木 福二 福島 正二

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.28, no.7, pp.239-244, 1981-10-25 (Released:2009-05-22)

- 参考文献数

- 2

- 被引用文献数

- 2

1 0 0 0 OA 第37回日本粉末冶金工業会賞―受賞製品の紹介―

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.63, no.4, pp.239-248, 2016-04-15 (Released:2016-05-07)

1 0 0 0 OA 永久磁石材料の電磁波吸収体への応用

- 著者

- 杉本 諭 籠谷 登志夫 前田 徹

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.53, no.3, pp.251-257, 2006 (Released:2006-08-18)

- 参考文献数

- 16

- 被引用文献数

- 1 2

Recently, the use of microwaves in the GHz range has increased because of the demand for large data transmission. However, the problem of electromagnetic interference (EMI) has become serious, and much attention has been paid to microwave absorption materials. We have investigated magnetic loss of permanent magnet materials at natural resonance frequency, and have succeeded in the development of microwave absorbers using M-type (or W-type ferrite) and RE-Fe-B (RE: rare earth) compounds. The resonance frequency can be controlled by substitution of Fe3+ ion with other metal ion in the M-type or W-type ferrite. The resin composite of M-type ferrite shows wide bandwidth, in which the reflection loss (R.L.) is less than −20 dB. In the RE-Fe-B compounds, the substitution of RE with Sm or the fabrication of nanocomposite with a soft magnetic phase is effective method for controlling their resonance phenomena and functional frequency as microwave absorbers. The powder with fine α-Fe structure, which is produced by the disproportionation reaction of RE-Fe compounds, is useful for the filler of resin composite microwave absorbers in several GHz range.