1 0 0 0 製鉄工業と輸送問題

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.47, no.12, pp.1663-1664, 1961

1 0 0 0 鐵の機械的性質に及ぼすマンガンの影響に就て

- 著者

- 嘉村 平八

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.20, no.7, pp.517-521, 1934

The specimens of manganese iron which contains up to 3.82% of manganese are made by the melted iron obtained from the sponge iron by hydrogen reduction with the metallic manganese in the market. Ten ingots of different manganese content are forged into the proper shape for the investigation. The measurement of electric conductivity, the mechanical testing and the microscopic investigation on the specimens were carried on as forged, annealed and quenched conditions.<BR>The electric resistivity of the annealed sample increases 0.6 microhm by incrensing 0.1% of Mn and that of the quenched sample is little higher than annealed ones The tensile strength and the elastic limit gradually increase up to 2% Mn, proportionally to the manganese content and over 2%, the ratio of increase is remarkable. In the quenched sample, these increase is marked up to 2% Mn, over 2%, the rate of increase in tensile strength is reduced and the elastic limit decreases suddenly. The elongation and the reduction area decrease exceedingly up to 0.2% Mn, over 0.2% they do not show much decrease by increasing the manganese content and over 2.2% Mn show sudden decrease. In the quenched specimens the rapid decrease of the reduction area is recognized increasing manganese under 0.67% and by increasing more manganese there is not much change in elongation and reduction area. But there is shown sudden decrease from 2.8% to 3.8% Mn in which malleability can hardly be recognized.<BR>The impact value is markedly reduced as the manganese content decreases. Especially in the annealed condition, this phenomenon is more marked, in 0.7% Mn it is 3kg. -meter. Then as the manganese content increases it suddenly goes up and reaches maximum, 13kg. -meter, in 2% Mn. Over this content of manganese it shows sudden decrease and in 3.8% there is almost no value in all conditions.<BR>In the micro-scopic investigation, the structure of low manganese specimens in annealed condition consist all ferrite crystals. When the manganese content increases to about 2% some martensitic structure appears and in 3.8% manganese it changes completely to martensite. In the quenched condition, the martensitic structure appears already in 0.677% manganese and the structure becomes completely martensite in 2% manganese.

1 0 0 0 轉爐と高周波電氣爐の併用による純鐵の製造

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.37, no.7, pp.394-396, 1951

The author proposes a process for making of pure iron by a duplex process of Bessemer converter and bigh frequency electric furnace as an economical induatrial process. The molten pig iron melted in a cupola furnace was blown in the basic or acid bessemer converter depending on the phosphorus content to eliminate the impurities. <BR>The carbon content in the blown metal was kept under 0.04 per cent. The refining of the blown metal was carried out in the high frequeney electric furnace with acid slag. The final metal obtained contained very small impurities and it is recognized that it is not difficult to make the carbon cont-ent of iron under 0.02 per cent and to deoxidize the metal by acid slag to obtain the pure iron with good mechanical properties.

- 著者

- 嘉村 平八

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.19, pp.5-6, 1933-10-16

1 0 0 0 水素に依ろ酸化鐵及び鐵鑛の還元

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.9, no.10, pp.699-708, 1923

- 被引用文献数

- 2

1 0 0 0 平爐に於ける餘熱の利用に就て

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.8, no.12, pp.863-866, 1922

1 0 0 0 鐵鑛の還元に就て

- 著者

- 嘉村 平八

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.11, no.1, pp.11-30, 1925

1 0 0 0 鐵鑛の還元に就て(其一)

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.10, no.7, pp.475-489, 1924

- 被引用文献数

- 1

1 0 0 0 鐵の磁氣的性質に及ぼす燐の影響に就て

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.21, no.8, pp.643-655, 1935

The author has been published on the effects of phosphorus as to the mechanical and physical properties of iron on this journal, Vol. XVIII, No. 4. This is the contuniation. of the previous investigation. It has been known that the magnetic properties of the iron is remarkably effected by small amount of impurities in it and the superior magnetic properties is obtained to eilminate the impurities as lower as possible in its manufacture.<BR>The author incidently discovered, in an occasion of investigation of iron made by the process of hydrogen reduction, that the phosphorus in the iron improves the magnetic properties of iron-that is high permeability and low hysteresis loss.<BR>In this research, the magnetic properties of phosphor iron, containing lower than 1% P was investigated. When the amount of phosphorus in the iron is about 0·7% the maximum permeability reached to 20, 000 and the hysteresis loss decreased to less than 1, 000 ergs. per sq. cm. per cycle; that is nearly correspond to three times in the maximum permeability and 60% in the hysteresis loss compared with the 3·5% silicon-steel in the market. When the phosphorus content is more than 0·5%, no ageing phenomena was obserbed. It was recognized that the proper annealing temperature exist by different phosphorus content to obtain best magnetic properties. In the investigation of the microscopic structure, the higher the phosphorus content in the iron the larger grain size was to be seen as in case of the silicon-steel, but it is not much remarkable when the phosphorus content reaches to more than 0·5%. When the annealing temperature is raised to the recrystalized range which is seen from the constitutional diagram of Fe-P, the deleterious effects on the magnetic properties was observed.

- 著者

- 嘉村 平八

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.19, 1933-04-03

1 0 0 0 OA 電氣製鐵に就て

- 著者

- 桂 辨三

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.2, no.10, pp.九九七-一〇一七, 1916-10-25

1 0 0 0 OA 中津鋼板(第 54 回講演大会工場見学記)

- 著者

- 服部 義雄

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.43, no.12, 1957-12-01

1 0 0 0 OA 氷の破壊靱性

- 著者

- 浦辺 浪夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.7, pp.908-916, 1981-05-01 (Released:2009-06-19)

- 参考文献数

- 26

1 0 0 0 OA 予備還元処理および物理選鉱による高リン鉄鉱石からのリン除去

- 著者

- 久保 裕也 丸岡 伸洋 佐藤 嘉将

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.9, pp.871-876, 2019 (Released:2019-08-31)

- 参考文献数

- 12

- 被引用文献数

- 3

Fundamental experiments were conducted with the aim of crude separation of the phosphorus contained in high-P iron ore prior to the ironmaking process. By reducing high-P iron ore with lime and graphite at an appropriate blending ratio and temperature, a reduction product was obtained consisting of a P-concentrated phase, metallic Fe with low P, and an Fe oxide-containing phase. The reduction product was pulverized by electrical pulse disintegration, and a magnetic separation experiment was performed for each particle group. As a result, 57.5% of the P contained in the reduction product was removed by removing particles of 250 μm or less. Samples simulating the constituent phases of the reduction products were synthesized and subjected to magnetization measurement. It was assumed that the Fe oxide-containing phase was paramagnetic and the P-concentrated phase was diamagnetic. We calculated the magnetic and drag forces acting on the paramagnetic particles in wet magnetic separation. When the magnetic field gradient was low, the magnetic forces acting on the fine particles were low, and attraction was difficult due to the drag force of water.

1 0 0 0 OA 知っておきたい金属凝固の基礎(III)

- 著者

- 郡司 好喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.6, pp.N266-N280, 1994-06-01 (Released:2009-06-19)

- 参考文献数

- 53

- 被引用文献数

- 1 3

1 0 0 0 高壓交流弧光の鐵鋼分光分析への應用

- 著者

- 三橋 鐵太郎 中島 篤之助 白石 裕子

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.39, no.11, pp.1277-1281, 1953

- 被引用文献数

- 2

Apparatus of the high voltage a. c. arc source (4400-2A; 2200V-4A) as the light source of spectrographic analysis was designed and manufactured, and the quantitative spectrographic analysis of manganse, titanium, silicon, nickel, chromium, and arsenic in steel was carried out by it. It was ascertained that the quantitative analysis which hsd been impossible for small amount of the above elements in steel in the usual spark discharge method, became possible in high sensitivity and about 3-8 percent reproducibility by the above apparatus.<BR>As for the other characteristic, it was proved that there was practically no continuous background and few loss of testpieces on account of a lower temperature of the electrode.

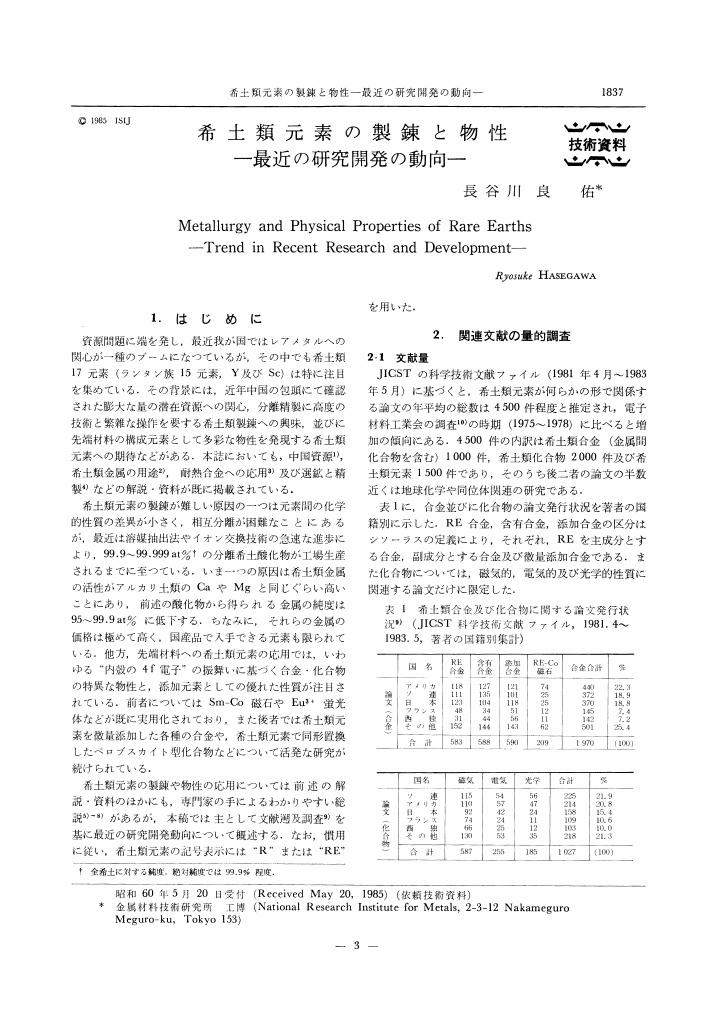

1 0 0 0 OA 希土類元素の製錬と物性

- 著者

- 長谷川 良佑

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.16, pp.1837-1845, 1985 (Released:2009-06-19)

- 参考文献数

- 34

1 0 0 0 OA 鉄仏の製作年代と古伝書「古今鍛冶備考」からみた銑押し法と〓押し法の成立期の検討

- 著者

- 鈴木 卓夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.97-102, 2005-01-01 (Released:2010-01-19)

- 参考文献数

- 15

- 被引用文献数

- 1 1

"Tatara" is a traditional box-type furnace in Japan and had produced iron from iron sand and charcol. In this Tatara there were two techniques which were called Zuku-Oshi and Kera-Oshi. Zuku means pig-iron and Kera means steel. The Tatara started in the latter half of six century and is continuing up to today. I am interested in when did the two techniques establish. So I tried to investigate the question with data of iron (pig-iron) image of Buddha making age and old document which is called "Kokon-Kajibiko". It is concluded that Zuku-Oshi has established regularly in Kamakura period (1192-1333). In Kera-Oshi case is the latter half of Muromachi period (1392-1573).

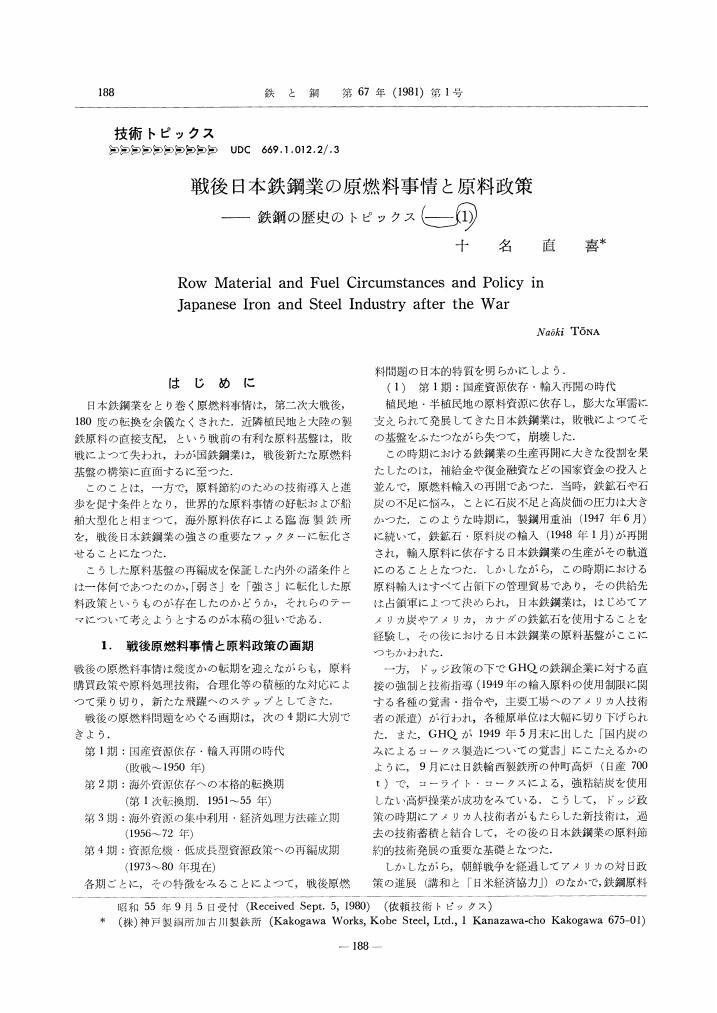

1 0 0 0 OA 戦後日本鉄鋼業の原燃料事情と原料政策

- 著者

- 十名 直喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.1, pp.188-191, 1981-01-01 (Released:2009-06-19)

- 被引用文献数

- 1

1 0 0 0 OA 低温度に於ける鋼材の特性

- 著者

- 長谷川 正義

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.41, no.4, pp.451-468, 1955-04-01 (Released:2010-01-19)

- 参考文献数

- 117

- 被引用文献数

- 1 1