1 0 0 0 OA 高周波プラズマによる超微粒子の作製

- 著者

- 吉田 豊信 明石 和夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.10, pp.1498-1502, 1982-08-01 (Released:2009-06-19)

- 参考文献数

- 28

- 被引用文献数

- 2 4

1 0 0 0 OA 雑録

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.41, no.1, pp.67-75, 1955-01-01 (Released:2009-07-09)

1 0 0 0 OA 随想 研究開発と寓話

- 著者

- 長島 晋一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.62, no.7, pp.787-788, 1976-06-01 (Released:2010-02-22)

1 0 0 0 OA 表面錆からみた稲荷山鉄剣の材質

- 著者

- 村田 朋美 佐々木 稔 田口 勇

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.16, pp.2087-2092, 1983-12-01 (Released:2009-06-30)

- 参考文献数

- 13

- 被引用文献数

- 1

1 0 0 0 OA コークス強度制御の高度化に向けた石炭利用技術

- 著者

- 有馬 孝 愛澤 禎典 野村 誠治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.2, pp.110-117, 2014 (Released:2014-01-31)

- 参考文献数

- 58

- 被引用文献数

- 3 5

Coking coal necessary for cokemaking process is exhausted in progress; increasing the ratio of non- or slightly-coking coal is required. However, non-or-slightly coking coal causes a lot of structural defects in the coke lump and decreases coke strength because of its low dilatation and high shrinkage.For increasing the ratio of non- or slightly-coking coal, pre-treatment technology of coal such as the coal size control, increasing the coal bulk density and the rapid preheating reforming etc. have been developed and a new cokemaking process SCOPE21 that consists of those technologies have already started and high quality of coke is produced using over 50% of non- or slightly-coking coal. In addition, knowledge of coke structure formation mechanism and degradation mechanism of coke were remarkably developed.This paper reviews the past research on coal utilization technologies, carbonization mechanism and coke structure and degradation behavior of coke, and describes future direction of research and development for increasing the ratio of non- or slightly-coking coal.

1 0 0 0 OA 薄鋼板におけるα→γ→α変態による集合組織形成

- 著者

- 橋本 修 佐藤 進 田中 智夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.1, pp.102-111, 1980-01-01 (Released:2010-01-18)

- 参考文献数

- 40

- 被引用文献数

- 19 15

For the purpose of investigating the formation mechanism of the texture which is developed by ferrite (α)→austenite (γ)→ferrite (α) transformation, the effects of heating and cooling rates during phase transformation and specimen thickness on the transformation texture have been studied by using extra low carbon sheet steel with the initial texture of {111}. The results obtained are summarized in the following: (1) Rapid heating and rapid cooling produced weak {100} and {111} texture. (2) Rapid heating and slow cooling exhibited both {110} texture and the orientation shifted 2030 degrees away from {100}. (3) Slow heating and slow cooling produced distinct {100} texture. (4) There was much difference in texture between surface and midsection of thick specimen: In the midsection, the texture similar to (1) was formed, independent of heating and cooling rates. While, specimen surface exhibited such textures as (1) to (3). (5) Those results were reasonably and consistently explained on the assumptions that the orientation relationship between bcc and fcc follows the Kurdjumov-Sachs relation, and that during α→γ→α transformation with slow rate such variants preferentially operate that undergo larger elastic work in normal direction of sheet.

1 0 0 0 OA 鉄鋼業におけるプロセス自動化のための新しい計測技術

- 著者

- 伊勢居 良仁

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.106, no.9, pp.591-601, 2020 (Released:2020-08-31)

- 参考文献数

- 58

- 被引用文献数

- 1

The instrumentation technology for process automation in the steel industry has been evolving with the demands of the times, adapting to its production process and its harsh environment as the latest measurement techniques applied by considering the physical measurement principles. Today, the instrumentation technology has become one of the essential technologies to maintain the competitiveness in the steel industry. In this review, the recent development trends and future prospects are described based on lectures and papers on process instrumentation technology published by the Iron and Steel Institute of Japan (ISIJ) in the last decade. The main challenges in recent steel processes were reducing greenhouse gas emissions, supplying high-quality products represented by high-strength steel sheets, and keeping stable operation without skilled workers. To meet these challenges, new measurement techniques that had been advanced in recent years, such as radio waves sensing, image processing, optical fiber sensors, and multivariate analysis, had been applied. The newly obtained process information contributes to further sophisticated processes automation, and is applied to Artificial Intelligence (AI) and Cyber-Physical Systems (CPS). In the next decade, it is hoped that the instrumentation technology will continue to make progress toward the establishment of a sustainable steel industry.

1 0 0 0 OA リン濃縮スラグからのリンの分離

- 著者

- 岩間 崇之 井上 亮 中瀬 憲治 植田 滋

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.109, no.1, pp.1-12, 2023 (Released:2022-12-31)

- 参考文献数

- 31

- 被引用文献数

- 4

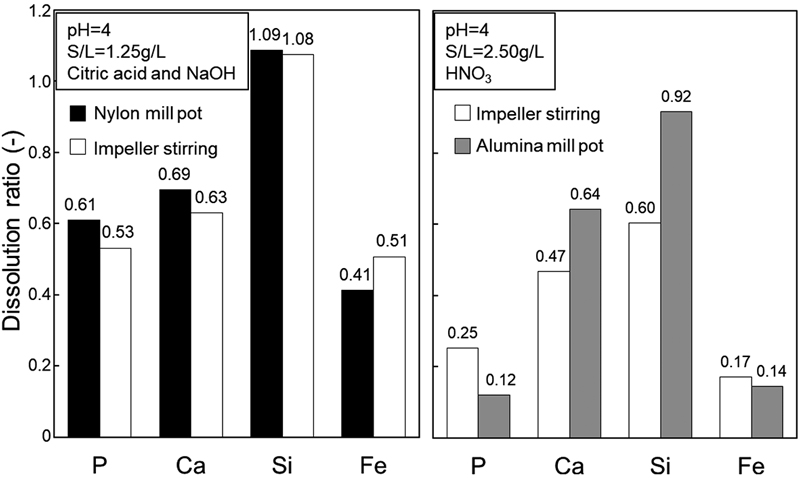

Since 10 million tons of steelmaking slag, which contains a few percent of phosphorus, are annually produced, the phosphorus amount in the slag is equivalent to the annual import volume of phosphorus rock in Japan. Therefore, the steelmaking slag is attracting attention as a potential phosphorus resources. Phosphorus-concentrated slag obtained by the dephosphorization reaction between high phosphorus hot metal and oxidizing slag at high temperature contains phosphorous comparable to that of phosphorus rock. However, because of high FeO concentration, it is difficult to use for phosphorus resources directly. In this work, the effects of pH, acid type and leaching method on the dissolution behavior of phosphorus from P-concentrated slag were investigated. As a result, phosphorus dissolution progressed at lower pH, and was promoted by the addition of citric acid, which is known as a chelate former. When nylon mill pot stirring with citric acid and alumina mill pot stirring with nitric acid were compared to impeller stirring, respectively. By combining nylon mill pot stirring and citrate leachate, phosphorus dissolution was accelerated, because the slag was pulverized during stirring and a formation of insoluble metal-phosphate was inhibited by the formation of complex ion between leached metal cation and citrate. When the slag was leached with alumina mill pot while controlling pH by nitric acid, the phosphorus dissolution ratio lowered since phosphorus ion and aluminum ion, which is supplied by the dissolution of pot and crushing ball during leaching, constructed secondary products with low solubility along with other dissolved ions.

1 0 0 0 OA 本邦製鉄事業の過去及将来

- 著者

- 野呂 景義

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.2, no.2, pp.159-167, 1916-02-25 (Released:2009-05-26)

1 0 0 0 OA 日本刀の有する硬度と比重に就て

- 著者

- 俵 国一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.5, no.11, pp.1234-1271, 1919-11-25 (Released:2009-07-09)

- 被引用文献数

- 1 1

1 0 0 0 OA 軸受鋼の寿命におよぼす熱処理組織の影響

- 著者

- 仕幸 三郎 岡本 一生 渡辺 章三

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.54, no.13, pp.1353-1366, 1968-11-01 (Released:2010-10-12)

- 参考文献数

- 21

- 被引用文献数

- 22 21

Effect of metallographical factors on the rolling fatigue life of 1%C-1.5%Cr bearing steel was investigated, and the most profitable component for the bearing life was discussed.The results obtained are as follows:(1) Metallographical factors affected on the rolling fatigue life of bearing steel were not amount and size of residual cementite but the chemical compositions soluted in fhe matrix.(2) The most effective factor affected on the rolling fatigue life was carbon content soluted in the matrix and the most desirable carbon content in the matrix was about 0.5 percent.(3) It was recognized that the mechanism of flaking was related to the third stage of the tempering of martensite. This was deduced from the observation of the micro-structure of cyclic stressed area by the transmission electron microscopy and the result of bearing life test of a new type steel with higher silicon of which the starting temperature of the third stage was rised by silicon.

1 0 0 0 OA 第95回講演大会討論会講演概要 II 溶銑の予備処理

1 0 0 0 OA 溶銑予備処理・転炉・介在物

- 著者

- 中村 泰 徳光 直樹 成田 貴一 佐藤 義智 久次米 章 伊藤 孝道 森 隆資 喜多村 実 熊井 浩 児玉 文男 大堀 佳彦 東口 方也 三好 俊吉 田口 喜代美 白谷 勇介 荒木 英夫 古賀 敬造 大喜多 義道 川見 明 中島 和徳 成田 進 海保 信恵 古崎 宣 増尾 久 尾上 俊雄 石井 照朗 植村 健一郎 加藤 直 平山 俊三 宇野 克洋 三崎 晴夫 桜場 和雅 木村 博則 丸川 雄浄 豊田 守 伊藤 洋一 矢野 芳則 米沢 戴 松原 嘉市 別所 勇 高田 寿

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.11, pp.S438-S449, 1974-09-10 (Released:2010-10-12)

- 被引用文献数

- 4 4

1 0 0 0 OA オーステナイト系ステンレス鋼における加工誘起変態挙動に及ぼす結晶粒径および転位密度の影響

- 著者

- 古金 駿 鳥塚 史郎

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.8, pp.827-836, 2019 (Released:2019-07-31)

- 参考文献数

- 46

- 被引用文献数

- 8 12

SUS316L is generally believed as a stable austenitic stainless steel, but strain-induced martensitic transformation can occur when large deformation is given. The predominant mechanisms, especially, in terms of the effect of grain size have been reported, however, it is not still clear. In this study, strain-induced transformation behavior of SUS316L steel was investigated from the points of grain size and dislocation density. Microstructures with various grain sizes and dislocation densities were fabricated by warm multi-pass multi-directional caliber rolling and annealing. Fully recrystallize microstructures with austenite grain sizes of 12, 18 and 27 µm were fabricated. Bimodal structures with ultrafine grains and coarse grains including high density dislocations were also fabricated. These specimens were rolled at a reduction strain from 0.12 to 2.7 at liquid nitrogen temperature to occur enough amount of strain-induced martensitic transformation. To evaluate martensite volume fraction in these cryogenic rolled materials, transmission type X-ray diffraction in synchrotron radiation of Spring-8 was used. Through thick XRD data can be obtained by this method. Regarding fully recrystallized materials, volume fraction of strain-induced martensitic transformation decreased with decreasing in grain size. It is very clear that gran refinement improves the mechanical stability of austenite. On the other hand, regarding bimodal structure, accumulated dislocations promote transformation, and transformation rates were higher with dislocation density at lower reduction strain area. However, saturated volume fractions decreased with decreasing in grain size. Therefore, strain-induced transformation is affected by both grain size and dislocation density having opposite effects, retarding and promoting the transformation.

1 0 0 0 OA 高炉スラグ中単体硫黄の吸光光度分析法

- 著者

- 小野 昭紘 山口 直治

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.10, pp.1377-1384, 1984-08-01 (Released:2009-06-30)

- 参考文献数

- 6

- 被引用文献数

- 7 5

A new spectrophotometric method for determination of elemental sulfur in blast furnace slag has been developed. The outline of the procedure is as follows. A slag sample is powdered with n-hexane using a disk mill and elemental sulfur in the sample is extracted into n-hexane at the same time. The ultraviolet absorption of the n-hexane layer is measured at 275 nm to determine the quantity of elemental sulfur.By using this method elemental sulfur can be determined with high accuracy, provided the amount is higher than 0.002%. The coefficient of variations at the 0.05 and 0.2% levels of elemental sulfur are 2.3 and 1.4%, respectively. The time required for analysis of one sample is less than 10 min. There is no interference effect for sulfur compounds in the slag sample such as sulfate, thiosulfate, sulfite, sulfide and poly-sulfides.When a slag sample is powdered under the dry condition before the n-hexane extraction, lower analytical values are obtained, because elemental sulfur changes into poly-sulfides by the reaction with Ca components of the slag sample. This chemical change is found to be suppressed by simultaneous performance of powdering and extraction. Based on this technique, an analytical method is proposed and successfully applied to determine elemental sulfur in a slag sample.

1 0 0 0 OA ベイナイトの等温変態挙動とその連続冷却変態への適用

- 著者

- 梅本 実 堀内 一也 田村 今男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.3, pp.461-470, 1982-03-01 (Released:2009-06-19)

- 参考文献数

- 23

- 被引用文献数

- 22 25

To obtain a general cooling transformation kinetics of steels from its isothermal transformation kinetic data, a bainite transformation has been investigated in present study. The main results obtained are as follows:(1) The isothermal transformation behaviour of bainite for the steel used in present investigation (JIS, SUJ2) can be expressed by the Johnson-Mehl type equation.(2) The bainite trasformation is retarded with an increase in the austenite grain size. The nucleation site of bainite is mainly on austenite grain surface but some homogeneous nucleations in the matrix are also found.(3) The equation expressing the transformation bahaviour of bainite during continuous cooling has been derived from the experimentally obtained isothermal transformation kinetics. It is examined that this equation well expresses the actual continuous cooling transformation behaviour.(4) The above result showing that additivity rule for transformed fraction is hold for bainite transformation during continuous cooling and cooling transformation behaviour can weell be predicted using the isothermal transformation kinetics.

1 0 0 0 OA 電磁熱流体力学の基礎と応用(II)

- 著者

- 棚橋 隆彦

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.79, no.4, pp.N263-N281, 1993-04-01 (Released:2009-06-30)

- 被引用文献数

- 1 2

1 0 0 0 OA 耐熱軸受鋼および耐食軸受鋼

- 著者

- 小柳 明

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.62, no.3, pp.414-423, 1976-03-01 (Released:2010-02-22)

- 参考文献数

- 35

- 被引用文献数

- 1

1 0 0 0 OA 二相混合組織をもつ鉄合金の強度と延性について

- 著者

- 田村 今男 友田 陽 山岡 幸男 金谷 三郎 小沢 正俊 赤尾 明

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.59, no.3, pp.454-468, 1973-03-01 (Released:2010-10-12)

- 参考文献数

- 21

- 被引用文献数

- 40 15

The strength and ductility of two-phase iron alloys with a ductile second phase were studied. The alloys used in this investigation were classified in three groups, that is, Fe-Cr-Ni alloys composed of austenite and ferrite, Fe-Ni-C alloys composed of austenite and martensite, and Fe-C alloys composed of ferrite and martensite; these phases had various volume fractions.The main results obtained are as follows:(1) In case of Fe-Cr-Ni alloys having different volume fractions of phases, when the same heat treatment was given, the better combination of strength and elongation was obtained in two-phase alloys than in single-phase alloys of austenite or ferrite. The main cause of this behavior was the difference in grain size. The coarsening of grains in two-phase alloys was much slower than that in single-phase alloys.(2) The effects of grain size on strength were shown by Petch type relations even in two-phase alloys as well as in single phase ones.(3) The effect of the volume fraction of phases on tensile properties with nearly the same grain size depended on the difference between the tensile properties of the second phase and the matrix. As the ratio of the 0.2% proof stress of the second phase to that of the matrix became larger than about 3, the relationb etween 0.2% proof stress and the volume fraction became to deviate from a linear relationship; this is known as the law of mixture. This may be caused by the difference of strains in the second phase and the matrix which becomes larger with an increase of the ratio.

1 0 0 0 OA 冷延鋼板のリン酸塩処理性に及ぼすCuとSnの影響

- 著者

- 大澤 紘一 濱田 紘一 峯 恭一 冨田 邦和 土谷 康夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.90, no.7, pp.494-501, 2004-07-01 (Released:2009-05-29)

- 参考文献数

- 15

- 被引用文献数

- 2 3

低C-Alキルド鋼をベースとして,Cu含有量を0.52mass%,Sn含有量を0.052mass%の範囲内で変化させた鋼種を用い,N,-3%H,雰囲気および1.3×10-2Pa以下の真空中で焼鈍した冷延鋼板におけるディップタイプのリン酸亜鉛化成処理性へのCuおよびSnの影響を調査し,つぎの結論を得た.(1)N2-H2雰囲気で焼鈍した冷延鋼板においては,052mass%まではCu含有量が増加しても化成処理性は若干低下する程度であるが,翫含有量の増加にともなって著しく化成処理性が低下する.(2)真空中で焼鈍した冷延鋼板においては,Cu,Sn共含有量の増加により著しく化成処理性が低下する.(3)焼鈍雰囲気が異なる場合の冷延鋼板の化成処理性へのCu,Snの影響に対して,焼鈍によるCu,Sn,Mn,Cなどの元素の表面濃化の寄与が大きいものと推察される.(4)スクラップの再利用により冷延鋼板を製造するに当たっては,Cu含有量に加えて,化成処理性を著しく低下させるSn含有量の上限管理が重要である.