- 著者

- 永塚 公彬 田中 宏宜 肖 伯律 土谷 敦岐 中田 一博

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.33, no.4, pp.317-325, 2015 (Released:2015-11-19)

- 参考文献数

- 37

- 被引用文献数

- 6 23

Dissimilar materials joining of an A5052 plate and a carbon fiber reinforced thermoplastic (CFRTP), which consisted of polyamide 6 (PA6) with 20 wt% carbon fiber addition, was performed using friction lap joining (FLJ) with the Al alloy plate as a top and the CFRTP plate as a bottom. The joint characteristics were evaluated to investigate effects of the surface treatment by the silane coupling treatment for A5052 and the joining speed on the joining properties. The joint strength was increased by inducing the silane coupling treatment for the A5052 plate surface. The tensile shear fracture load of the silane coupling treated FLJ joint increased with increasing the joining speed up to 6.67mm/s, and then decreased. The maximum tensile shear fracture load of 5.0kN was obtained at the joining speed of 6.67mm/s, and the fracture occurred at the CFRTP base plate with the joint efficiency of 97%. The shear strength of the joint interface of the joint formed at the joining speed of 1.67mm/s, which fractured at the joining interface by the tensile shear test, was estimated about 19MPa. The covalent bondings between the A5052 plate and the silane coupling layer, and the silane coupling layer and the CFRTP plate were indicated by inducing the silane coupling treatment.

- 著者

- 前中 浩 佐久間 正明 松岡 一祥

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.4, no.1, pp.95-101, 1986-02-05

The stress relief phenomena in pre-loading on butt welded plates and the changes of material properties owing to the pre-loading were investigated theoretically and experimentally. A over-matching welded joint composed of a 50 kgf/mm^2 class weld metal by automatic CO_2 welding and a mild steel of 16 mm thickness was tested. The strain distributions measured by strain gages showed the same tendency to those calculated by FEM, under pre-loadings in directions perpendicular and parallel to the weld line. The perpendicular loading was superior to the parallel loading in terms of reducing the plastic strains caused of the stress releaving. Strain aging embrittlement of weld metal, HAZ and base metal obtained by 2 mm V notched Charpy test was quite proportional to prestrain, and significant difference among them could not be found. The equations for estimation of the brittle fracture initiation temperature were checked. The rise in the temperature caused by the pre-loading was less than that due to the weld residual stress. It was concluded that the effective pre-loading method recommended in the present paper was sufficiently safe.

1 0 0 0 OA 原子炉圧力容器肉盛溶接部における溶接及び溶接後熱処理による残留応力分布評価

- 著者

- 宇田川 誠 勝山 仁哉 西川 弘之 鬼沢 邦雄

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.28, no.3, pp.261-271, 2010 (Released:2010-07-29)

- 参考文献数

- 19

- 被引用文献数

- 2

Austenitic stainless steel is welded as a cladding on the inner surface of a reactor pressure vessel (RPV) made of low alloy steel. In order to assess the structural integrity of the RPV precisely, the residual stress distribution caused by weld-overlay cladding and post-weld heat treatment (PWHT) is evaluated. Since the cladding layer is very thin compared to vessel wall, it is necessary to evaluate the residual stress distribution around the weld fusion line can be very steep. In this study, cladded specimens were fabricated using different welding methods. Residual stress measurements using both sectioning and deep hole drilling (DHD) methods were then performed to evaluate the residual stress distributions through the weld fusion line. Three-dimensional thermal-elastic-plastic-creep analyses based on finite element method were also conducted to evaluate the residual stress caused by weld-overlay cladding and PWHT. It was shown that analytical results provided reasonable agreements on weld residual stress with experimental results. It was also clarified that the main cause of residual stress due to welding and PWHT was the difference of thermal expansion between weld and base metals.

1 0 0 0 溶込み不足つき角継手の疲労強度について

- 著者

- 寺崎 俊夫 福田 貴生 北村 貴典 増本 展祥

- 出版者

- JAPAN WELDING SOCIETY

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.19, no.3, pp.564-569, 2001

This paper deals with a fatigue strength of corner joint without backing plate using experimental data and numerical method. A lack of penetration is usually found at the root of the corner joint. The fatigue strength generally depends on the lack of penetration. From comparing between experimental data of fatigue strength and numerical results, it is shown that a stress intensity factor is useful for predicting the fatigue strength of the corner joint. The stress intensity factor is calculated under condition with changing main factors of corner joint. It is suggested that the plate thickness and the length of lack of penetration are main factors of the fatigue strength of the corner joint.

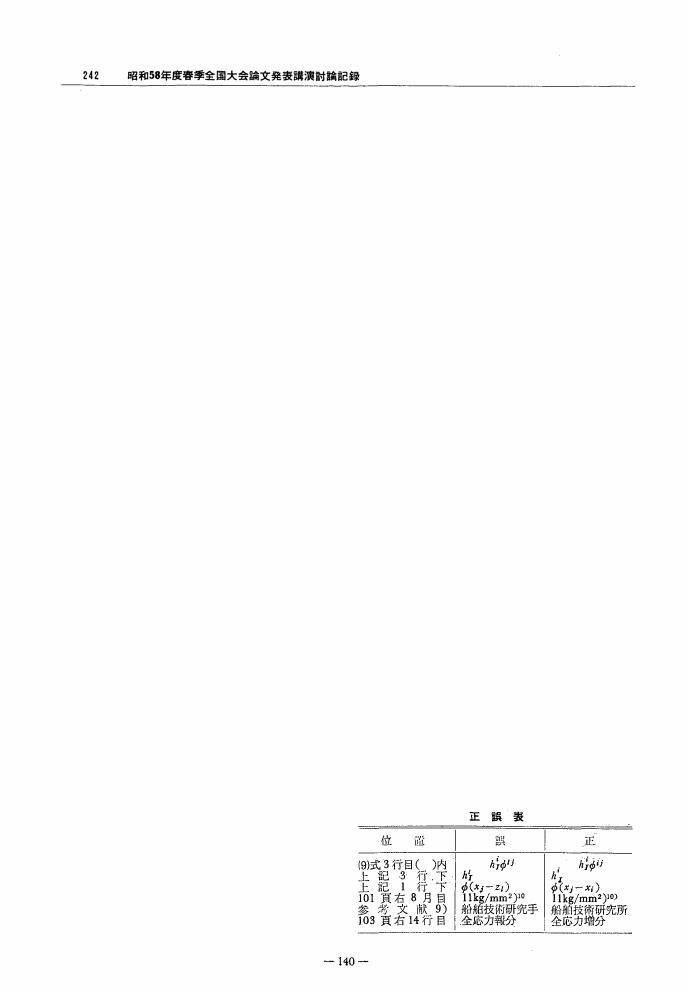

1 0 0 0 OA 正誤表

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.1, no.2, pp.242-242, 1983 (Released:2009-12-10)

1 0 0 0 溶接残留応力の機械的除去に伴う材質変化の評価

- 著者

- 前中 浩 佐久間 正明 松岡 一祥

- 出版者

- JAPAN WELDING SOCIETY

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.4, no.1, pp.95-101, 1986

The stress relief phenomena in pre-loading on butt welded plates and the changes of material properties owing to the pre-loading were investigated theoretically and experimentally. A over-matching welded joint composed of a 50kgf/mm<SUP>2</SUP> class weld metal by automatic CO<SUB>2</SUB> welding and a mild steel of 16 mm thickness was tested.<BR>The strain distributions measured by strain gages showed the same tendency to those calculated by FEM, under pre-loadings in directions perpendicular and parallel to the weld line. The perpendicular loading was superior to the parallel loading in terms of reducing the plastic strains caused of the stress releaving.<BR>Strain aging embrittlement of weld metal, HAZ and base metal obtained by 2 mm V notched Charpy test was quite proportional to prestrain, and significant difference among them could not be found. The equations for estimation of the brittle fracture initiation temperature were checked. The rise in the temperature caused by the pre-loading was less than that due to the weld residual stress. It was concluded that the effective pre-loading method recommended in the present paper was sufficiently safe.

- 著者

- 大橋 修 菅 誠一郎

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.10, no.1, pp.53-58, 1992-02-05

- 被引用文献数

- 8

The purpose of this study is to investigate the effect of twist angle on tensile strength of diffusion-welded joints by using molybdenum single crystals with (121) and (025) surfaces. Relation between the twist angle and strength is tried to explain with the coincidence site lattice model and a theoretical model calculation. The results are as follows : Single crystals could be welded without recrystallization. Tensile strength of the joints depended on the twist angles. The joints with twist angles up to 10 degree were as strong as the base metal. In case of the twist angles above 10 degree, there were peaks in tensile strength of the joints around the certain twist angles where a number of common lattice points were formed at welding interface. From the calculation, it was shown that the binding energy between the crystals decreased with decreasing the number of common lattice points. Twist angle widths of peaks in tensile strength were estimated with the Brandon's equation.

1 0 0 0 OA すみ肉溶接で生じる面外変形の高精度予測

- 著者

- 金 裕哲 李 在翼 猪瀬 幸太郎

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.23, no.3, pp.431-435, 2005-08-05

- 被引用文献数

- 13 23

In order to predict the distortion generated by welding with high accuracy, distortion with fillet welding was measured by three-dimensional photographic measurement. Then, the experiment was simulated by three-dimensional thermal elastic-plastic analysis by FEM. The important matters that should be noted on predicting the distortion with high accuracy were shown by comparing with the results of the experiment and those of the analysis. The results of measuring temperature could be accurately simulated by non-steady state thermal conduction analysis based on FEM. In carrying out the elastic-plastic analysis, four conditions (equilibrium equation, constitutive equation, condition of compatibility and yield condition) should be satisfied. In welding, the temperature largely changed from a melting temperature to a room temperature. So, yield stress of materials largely changed, too. In particular, yield stress becomes about zero above 700℃. The analysis should be carried out under the yield condition that equivalent stress generated in temperature increment ΔT did not exceed yield stress of materials at high temperature above 700℃. It should be sufficiently recognized that the obtained results were not reliable if the yield condition was not satisfied. Angular distortion generated in fillet welding could be accurately predicted by regarding the weld metal as a deposited metal not assuming that a deposited metal zone was a simple triangle. Specifying an influence factor on longitudinal bending distortion was difficult because the absolute value was small. However, it was indicated that the reasonable result could be obtained by regarding the weld metal as a deposited metal because the absolute value of longitudinal bending distortion at pass (2) (the second pass) of which restraint was severer became smaller than that at pass (1) (the first pass).

1 0 0 0 OA ガストンネル型プラズマ溶射装置による溶射粒子の付着特性とセラミックス皮膜特性

- 著者

- 小林 明 栗原 摂 羽原 康裕 荒田 吉明

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.8, no.4, pp.21-27, 1990-11-05

- 被引用文献数

- 2

The deposit characteristics of ceramic powder sprayed onto a substrate by the gas tunnel type plasma spraying apparatus were studied, and it was found that the special spraying distance L^* can be determined by the deposit characteristics. The relation between the deposit characteristics and the coating quality such as the Vickers hardness and porosity was discussed and it was clarified that the special spraying distance L^* governing deposit characteristics corresponded to the critical spraying distance L_c which indicated the largest distance in order to obtain the good coating quality.

1 0 0 0 OA レールテルミット溶接部の疲労強度向上に関する検討

- 著者

- 上山 且芳 深田 康人 山本 隆一 辰巳 光正 坂下 積 杉野 和男 鈴木 理三郎 大原 宗行

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.21, no.1, pp.87-94, 2003 (Released:2004-06-30)

- 参考文献数

- 23

Thermite welding is widely used in the world. In the Japan railway company group, the application ratio of this method is approximately 40 % every year. The reasons why the thermite welding method is widely used are that the equipment has good mobility and the total working time of that is shorter than that of the enclosed arc welding method on site. Moreover, the operating skill, which is required for thermite welding, is less than that for enclosed arc welding. This welding method used now was introduced into Japan from Germany in 1979. After that, the thermite welding technique has been improved and developed. A wide gap method is one of newly proposed thermite welding in Japan. The root gap of this method is three times for that of conventional method. Therefore, it is feared that welds produced by wide gap method have less fatigue strength than those by conventional method. Because a welding heat input of wide gap method is much larger than that of conventional method. In this investigation, a new process with rail head air cooling for wide gap thermite welding is proposed in order to improve fatigue strength of thermite welded joint on rails.

1 0 0 0 OA PWMインバータによる連続フラッシュ制御法

- 著者

- 佐藤 之彦 石田 宗秋

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.22, no.3, pp.424-429, 2004 (Released:2005-08-01)

- 参考文献数

- 3

- 被引用文献数

- 1 1

In previous study, flashing phenomena in square wave alternating current have been discussed for flashing control. The results give a suggestion that PWM inverter has possibility to control flashing phenomena in half a cycle. In this study, flashing phenomena control strategy for flash welding is discussed by use of PWM inverter power supply. The results are summarized as follows : 1 PWM inverter enables to control flashing phenomena in half a cycle. 2 PWM inverter control for continuous flashing is proposed.

1 0 0 0 OA すみ肉T継手に生じる縦収縮・縦曲り変形に関する研究

- 著者

- 寺崎 俊夫 北村 貴典 城戸田 巌 石村 知樹 浜島 志伸

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.21, no.1, pp.81-86, 2003 (Released:2004-06-30)

- 参考文献数

- 10

- 被引用文献数

- 8 12

This paper deals with experimental data and a predictive method of longitudinal shrinkage and bending distortion which are important in the development of the high accuracy production system of the large welding structures. The longitudinal shrinkage and bending distortion can be calculated from the inherent force, namely Tendon Force, which is related to the total of the inherent strain. First the experimental values of the longitudinal shrinkage, longitudinal bending distortion and the inherent strain were obtained under various welding conditions. Next, the theoretical equation was proposed to calculate the longitudinal shrinkage and bending distortion from the inherent strain. As the results, the validity of the theoretical equation on the longitudinal shrinkage and bending distortion is shown by the comparison between values predicted from inherent force and experimental values.

1 0 0 0 OA TiAl金属間化合物と構造用鋼の拡散接合部の強度特性

- 著者

- 瀬戸 佐智生 松本 浩司 増山 智将 廣島 美佐 石川 博俊

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.16, no.1, pp.59-65, 1998-02-05

- 被引用文献数

- 1

In this research, diffusion bonding of the intermetallic compound TiAl containing Fe, V, B and SACM645 steel was investigated. Relationships between strength characteristics and bonding parameters were analyzed. Main results obtained are as follows, (1) Direct diffusion bonding of TiAl and SACM645 was possible, high strength joints were obtained by selecting short bonding time with the bonding temperature in the range of 1223〜1283K.(2) In the bonding interface, two or three inter-layers were formed as diffusion process proceeded. Decarburized layer at the steel side, Fe-Al-Ti type layer and TiC layer at the TiAl side were formed.(3) High strength joints were obtained by suppressing the formation of TiC compound in the bonding interface and by controlling total width of inter-layers within 5μm.

1 0 0 0 OA 走査電子顕微鏡による二次電子放出特性を用いた立体像の構築とその応用

- 著者

- 村田 雅人 向井 喜彦 田口 佳男 堀田 昌直

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.9, no.3, pp.134-139, 1991-08-05

- 被引用文献数

- 7

Intensity of secondary electron induced by incident electron beam depends on a degree of inclination of surface. In the present work, 3-dimensional image for fracture surface was tried to constitute by applying this secondary elecron property with improved type SEM equipment which had four secondary electron detectors to remove a image distortion caused by observating direction. As the results, we could obtain 3-dimensional image and measured direction depth of fracture surfaces by real time treatment with 32 bit personal computer. In the case, the calculation time for one fractograph analysis was about only 5 minutes.

1 0 0 0 OA 高Mn非磁性鋼と炭素鋼との溶接継手の継手特性と疲労強度

- 著者

- 中地 映司 池田 惣一 金 裕哲 中辻 義弘 堀川 浩甫

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.15, no.3, pp.535-540, 1997-08-05

- 参考文献数

- 7

The dissimilar materials welded joints of high manganese non-magnetic steel/carbon steel(hereafter refered to as DMW joints), in which weld defects such as hot crack or blowhole are not found, were the good quality. Tensile strength of DMW joints was 10% higher than that of the base metal of carbon steel. In the bend tests, the DMW joints showed the good ductility without crack. Charpy absorved energy at 0 (℃) of the DMW joints was over 120 (J) in the bond where it seems to be the lowest. Large hardening or softening was not detected in the heat affected zone. Fatigue strength of the DMW joints is almost the same with that of the welded joints of carbon steel/carbon steel. As the fatigue strength of the DMW joints exceeds the fatigue design standard curve of JSSC for carbon steel welded joints, the DMW joints can be treated the same as the welded joints of carbon steel/carbon steel of which strength is lower than that of high manganese non-magnetic steel, from the viewpoint of the fatigue design.

- 著者

- 篠崎 賢二 羅 湘軍 有吉 秀文 黒木 英憲 白井 誠

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.17, no.2, pp.286-293, 1999-05-05

- 被引用文献数

- 11

This study was carried out quantitatively to evaluate the hot cracking susceptibilities of various Ni-base superalloys and the effect of grain size on hot cracking susceptibility during laser welding. Ni-base superalloys used were Inconel 718,Inconel X-750,Inconel 617,Inconel 625,Nimonic 90 Waspaloy, Hastelloy X. The grain size of Inconel 718 varied from about 10 to 110 μm. In this study, the hot craking susceptibility was evaluated by a modified U-type hot cracking tester during CO_2 laser welding. Samples were solution heat-treated before welding and welded with laser powers of 3 and 5 kW and with a traveling speed of 0.5 to 3 m/min. The hot cracking occurring in the weldment during the bead on plate test was reproduced on the U-type hot cracking test. Consequently, the liquation cracking susceptibilities of various Ni-base superalloys decreased in the order of Waspaloy, Inconel 617,Inconel 718,Hastelloy X, Inonel 625,Inconel X-750 and Nimonic 90. Liquation cracking susceptibility of Inconel 718 increased with an increase in grain size.

- 著者

- 松田 福久 上山 智之

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.11, no.1, pp.95-101, 1993-02-05

- 被引用文献数

- 6

Solidification crack susceptibility in partially-melted bead-on-plate laser beam weld metal of 6 mm trick 0.2C-1.8Ni-0.55Cr-0.2Mo low alloy steel has been investigated with change of S and P contents in steel using maximum 5 KW CO_2 laser facility beam welder. Effect of weld bead configuration and amount of S and P on crack length in crosssectional bead have been mainly investigated. Estimation of crack length in weld metal was tried by means of regression analysis of data, using bead configuration and impurities of S and P. Moreover, effect of restraint of weld bead during welding on crack susceptibility was investigated. Main results obtained are as follows ; 1) Weld bead configuration is gradually changed from winecup-type to well-type with changing to higher power and higher welding speed in laser beam welding (LBW) within the welding condition in this investigation. 2) With an increase in weld power and welding speed solidification crack susceptibility in weld bead is increased. 3) Solidification cracks have been seen both winecup-and well-type weld bead. However, the cracks were much more in well-type bead than in winecup-type bead in general. 4) S and P impurities in steel have a detrimental effect for the cracks. However, S is 1.8 times more detrimental than P according to statistical investigation. 5) According to statistical investigation the cracks increase with an increase in length of side wall fused and of d_<B1/2> (bead width in 1/2 penetration) 6) The equation which can estimate the crack length in weld bead is introduced from the statistical investigation using the factors of bead configuration and impurities (S, P) in steel. 7) The restraint of the specimen during welding increases the crack susceptibility in weld bead in comparison with the restraint free bead.

1 0 0 0 OA 低変態温度溶接材料を用いた角回し溶接継手の疲労強度向上

- 著者

- 太田 昭彦 渡辺 修 松岡 一祥 志賀 千晃 西島 敏 前田 芳夫 鈴木 直之 久保 高宏

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.18, no.1, pp.141-145, 2000-02-05

- 参考文献数

- 18

- 被引用文献数

- 22

The fatigue strength of developed box welds was improved about two times of the conventional box welds. The improved welds used the low transformation temperature welding material which contains 10% Cr and 10% Ni. The expansion of the developed welding material was 0.55% due to the transformation from austenite to martensite. This expansion induced the compressive residual stress around welds. On low stress range condition, the stress ratio effect by this compressive residual stress avoids the fatigue crack initiation at the weld toe. On high stress range condition, the fatigue crack initiated from weld toe and the fretting was observed on the fractured surface. While in the conventional welds, no trace of fretting was observed.

- 著者

- 中村 照美 平岡 和雄

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.19, no.1, pp.44-53, 2001-02-05

- 被引用文献数

- 19

Narrow gap welding (NGW) joints offers many advantages over conventional welding methods, such as good mechanical properties of joints, high welding efficiency and low residual stress. As the groove gap width becomes narrower, the arc heat input can be reduced and the merits in narrow gap welding increases more. Generally, GMA welding method has been never applied to less than 5 mm groove gap, because it is guessed that it is arc instability and lack of fusion at the groove bottom area occur. In this paper, first of all, arc behavior under narrower gap joints is discussed, and it was concluded that the arc in MIG arc welding irregularly perturbates up-to-downwards along the groove wall under less than 5 mm gap, but CO_2 arc was stable under narrower gap. Next, penetrations at the groove bottom area in CO_2 arc welding were discussed. Characteristics of bead formation phenomena in CO_2 buried arc welding of bead-on-plate were analyzed. From the results, the relationship between hydrostatic potential of molten metal and arc force corresponding with welding current was estimated. Furthermore, the width of gauging region of penetration by arc force was measured and the relationship between the melting width at groove bottom and welding conditions (welding current and welding speed) can be suggested. With these results, numerical simulation model was proposed and the optimum welding conditions to melt the groove bottom area sufficiently and to minimize heat input were searched by numerical simulation. And then narrow gap welding with 5 mm groove gap was carried out using these simulated welding conditions. In the experimental results, the weld bead was obtained without lack of fusion at groove bottom, but the convex surface bead was formed which is disagreeable in multi-pass welding. The new welding process was proposed from numerical simulations in order to prevent this convex bead and to obtain sufficient melting at bottom area. In the new process, the wire extension can be controlled by welding current waveform and then arc regularly oscillated up-to-downwards along the groove wall. In this arc oscillation, arc heating distribution along groove wall 1ed to both sufficient penetration at groove bottom and concave surface bead shape.

1 0 0 0 OA 宇宙ステーション軌道圧力でのGHTA溶接実験

- 著者

- 吹田 義一 正箱 信一郎 佐藤 順子 黒川 哲平 高井 大輔 佃 芳行 寺嶋 昇 藤澤 正一郎 黄地 尚義 増渕 興一

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会論文集 : quarterly journal of the Japan Welding Society (ISSN:02884771)

- 巻号頁・発行日

- vol.21, no.1, pp.33-38, 2003-02-05

- 被引用文献数

- 6 8

As a welding method in space, the authors have proposed the GHTA (Gas Hollow Tungsten Arc) welding method in the previous papers, where some GHTA welding experiments have been conducted under the condition of low pressure (10^-2 Pa) and/or the micro-gravity. In the present paper, a feasibility study has been conducted whether the method can be used under such a high vacuum condition (10^-5 Pa) as on the space station orbit. As a result, it is made clear that the GHTA method is quite feasible under the high vacuum condition and its melting process strongly depends on the operating gas species such as Ne, Ar and Kr. Increasing the flow rate of operating gas decreases the mass of metal vapor from molten pool and the use of a heavy operating gas such as Kr also decreases the mass of metal vapor.