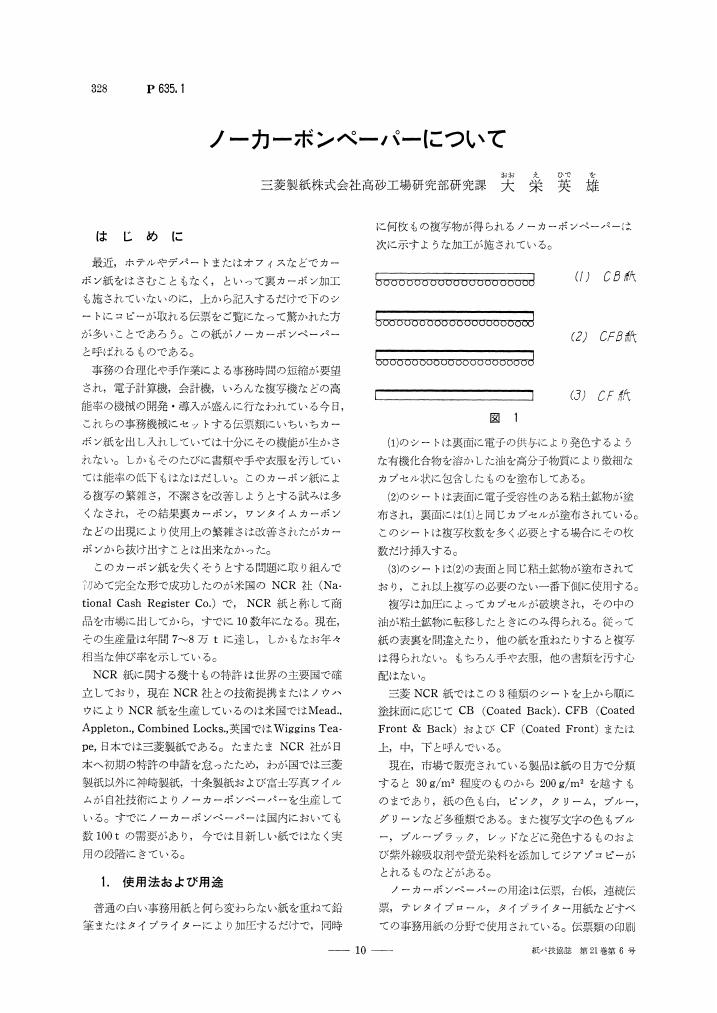

1 0 0 0 OA ノーカーボンペーパーについて

- 著者

- 大栄 英雄

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.21, no.6, pp.328-332, 1967-06-01 (Released:2009-11-11)

- 参考文献数

- 16

1 0 0 0 OA 高填料充填紙について

- 著者

- 小泉 正弘

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.42, no.11, pp.1022-1028, 1988-11-01 (Released:2009-11-16)

- 参考文献数

- 11

- 被引用文献数

- 1

1 0 0 0 OA 制御技術 / 理論の歴史と現在とこれから

- 著者

- 広井 和男

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.51, no.3, pp.514-527, 1997-03-01 (Released:2010-02-22)

- 参考文献数

- 14

Effectiveness of the plant control systems depends on the level of the control technologies built in the systems. In the twenty first century, more advanced control technologies will be indispensable in areas of safe and flexible plant operations, energy and resources saving, and environment maintenance.This paper reviews the history of control technologies and theories, the development and interaction of them, and presents the author's view on the current results and the future issues. In the sixty years since the introduction of PID control, various other control technologies and theories were tried but none has replaced PID nor taken the the lead in control. In the present age of digital control, the PID control is still in dominant use with more than 90% of all controls, and no immediate change is anticipated.From these facts, in order to achieve more advanced operation of plants, it will be necessary to further refine the PID control and apply non-PID control in more effective and Practical ways. I have pointed out that in the PID control, which is the basis of the control system, there are still unknown areas and those portions that need further refinements, and as an example of advanced PID control, explained the two-degree of freedom PID control. Since the characteristics of control object often vary considerably in the process control, the refinement of control can be said to be a fight against the change of characteristics of the control object. With these facts in mind, I have explained that, to further advance the plant control, many sided approaches are required including the refinement of classical control and the wide and practical applications of modern control, knowledge control, and other new control theories. In developing them, realization of control technologies that are both effective and user-friendly is strongly desired.

1 0 0 0 OA 非木材繊維利用の現状と将来

- 著者

- 森本 正和

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.51, no.6, pp.895-914, 1997-06-01 (Released:2009-11-19)

- 参考文献数

- 40

- 被引用文献数

- 2

Aspects of the global utilization of nonwood plant fiber pulp are reviewed compared with that of woodpulp and waste paper, referring the data from FAO Yearbook 1994 and PPI July 1995. The ratio of nonwood pulp produced in the world attained to ca. 12% of all pulp produced in 1994. Characteristic differences between nonwood pulp and wood pulp, which are important to paper making use of them, are also reviewed on the point of morphological features of component cells and chemical composition of each pulp.

1 0 0 0 OA ペーパーコーティング用薬剤について

1 0 0 0 OA 塗布・製紙工程の流動シミュレーション

- 著者

- 安原 賢

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.71, no.7, pp.786-798, 2017 (Released:2017-10-01)

- 参考文献数

- 38

化学工学の分野で塗布は重要な要素技術であり,日本の産業界ではVOF 法を用いた塗布ビードの自由表面解析が盛んに行われてきた。この解析手法にて,空気同伴,リビング,リビュレット,段ムラ,塗布エッジ膜厚不均一等の各種塗布故障が解析結果として再現された。また,これら塗布故障の発生状況と塗布条件の相関を定量的に整理したコーティングウィンドウにおいても,実際の塗布試験結果と良好な一致が見られた。このように,塗布解析を活用した塗布故障発生原理の解明,未知の操業条件における塗布故障発生予測が実用化され,近年では主に電子材料分野の塗布最適設計に役立っている。現状この分野では,スロット塗布方式による単層塗布が一般的だが,多層同時塗布技術の応用も期待されている。他方,製紙業界の分野では,流体構造連成解析によってブレード塗工挙動を表現し,ブレードやゴムロールという弾性体にニップされつつ塗工膜を形成する挙動が再現されたが,ここでは紙基材への染み込みまでは考慮しきれていない。但し,印刷プロセス解析では,染み込みモデルによってポーラスな紙面へ液体が染み込む挙動が既に再現されており,ブレード塗工との同時考慮が今後の課題である。また,流体粒子連成解析を応用した塗工液中の固体微粒子挙動の解明,更には粒子を数珠状に軟連結した微細繊維挙動解析による抄紙工程の繊維挙動解明も期待される。

1 0 0 0 OA 最近の計装技術 (VII)

- 著者

- 本間 忠一

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.44, no.6, pp.686-698, 1990-06-01 (Released:2010-04-23)

This scrial report describes current topics in pulp and paper process instrumentation rechnology, and this paper focuses on the automation technology that Yokogawa Electric Co. provides for the pulp and paper industry.

1 0 0 0 OA 本邦SCP工業の現状並びに今後の問題点

- 著者

- 満永 道夫

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.11, no.5, pp.298-306, 1957-05-10 (Released:2009-11-18)

- 参考文献数

- 8

1 0 0 0 OA 紙の平滑度と印刷適性について

- 著者

- 畑 幸徳

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.14, no.2, pp.90-98, 1960-02-10 (Released:2009-11-17)

In order to establish the standard printability testing method, printing experiments were carried out conbined with orthogonal array which composed with 18 papermaking factors and 7 printing factors .48 samples, consist of finepaper, photo-gravure and newspaper, were made on the test fourdriniermachine.Some parts of each sample were tested physical properties, and the rest were printed by letterpress, lithography or rotogravure on a test rotary printing machine.Each printed sample was determined ink transfer number, printed opacity, and reflection index, specular gloss and uniformity of printed surface, and the results were analysed statistically in order to obtain the relation between printing results and papermaking factors, printing factors or physical properties of sheet.Some experiments were carried out to printing results.Smoothness of paper were tested by 4 types of tester, all the results indicated that smoothness highly correlated with printing results.Among the contributions of all factors on printing results, in the case of fine paper, printing factors are generally greater than others, but in the case of newspaper and photogravure, paper making factors are dominant.Generally speaking, printing factors have greater effect to the ink transfer number and reflection index of printed surface than paper making factors.For the printed opacity and specular gloss of printed surface, this relationship is reversal.Among paper making factors, smoothness is the greatest for any printing results, so that smoothness is the most important in the printability of paper.

1 0 0 0 OA 蒸気タービン誘導発電機の導入

- 著者

- 早坂 大助

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.55, no.5, pp.621-625,022, 2001-05-01 (Released:2010-10-27)

2000年8月, 小型蒸気タービン誘導発電機を導入した。当工場では, これまで発電設備がなく電力は全て購入電力であったため, 電力料金の工場のエネルギーコストに占める割合は非常に大きなものとなっていた。蒸気タービン発電機を導入したことにより当工場の第一号発電機となり, ここに岩渕工場発電所が誕生した。構内で蒸気を最も多く使用する設備は工場の主力である3, 4マシンであり, ボイラーより蒸気圧力1.1MPaで供給し直前にて減圧弁で蒸気圧力0.3MPaに下げて使用していた。この減圧による熱落差のエネルギーロスを有効利用すべく出力385k Wの蒸気タービン誘導発電機を設置した。導入効果としては予定通り全使用電力の約3%を自家発電することとなり, エネルギーコストも目的通り節減が計られた。今回こうした導入経緯, 設備概要, 効果等, エネルギーコスト削減の一例とし紹介する。

1 0 0 0 OA 海外技術ニュース

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.33, no.5, pp.Preface2-Preface8, 1979-05-01 (Released:2009-11-10)

1 0 0 0 OA 微生物によるリグニン分解

- 著者

- 西田 友昭

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.43, no.11, pp.1071-1084, 1989-11-01 (Released:2009-11-16)

- 参考文献数

- 79

- 被引用文献数

- 1 1

1 0 0 0 王子マテリア株式会社 名寄工場

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.68, no.6, pp.679-684, 2014 (Released:2014-09-01)

- 被引用文献数

- 1

1 0 0 0 OA 紙の発生から普及まで (14)

- 著者

- 伊藤 通弘

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.50, no.10, pp.1445, 1996 (Released:2009-11-16)

1 0 0 0 欠陥検査システムのデータ管理とオープン・アクセス

- 著者

- 黒崎 篤

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.60, no.8, pp.1167-1172, 2006

コグネックス社の欠陥検査システム「SmartView®(スマート・ビュー)」は,Windows PCサーバを中心としネットワークでオープン化されている。OPC/ODBCや独自のソフトウェア・ツールを利用して,各工程・各セクションにおいて必要な検査データを自由に取り出し活用することができる。例えば,(1)欠陥種類や位置情報に基づきワインダーを自動停止させる,(2)加工部門において小巻ロールごとに欠陥情報を編集する,(3)品質管理部門において欠陥のトレンドやプロファイルを解析し発生原因を解明する,など。欠陥検査システムの持つ豊富な情報をいかに活用していくかの視点から,「SmartView®(スマート・ビュー)」が持つ情報技術を説明する。

It has been known that molding characteristics were important factors which contributes to compressive properties among various ones forming the compressive properties of a corrugated fiberboard container. In this study, sources of the vibration on the high-low corrugation as well as the relation between the high-low corrugation and physical properties of corrugating medium were investigated.<BR>The results showed that the resonance of the vibration clearly existed at the velocity of 130 m/ min on the single-facer, and that the vibration remarkably influenced a high-low corrugation. It was also found out that the bite of corrugator rolls mainly caused the vibration. The frequency (f) of the vibration is represented as f=n (number of the gear) × (revolution of the corrugator roll), here n is integer. It was clarified that the resonance occured when the frequency became near or agreed with the natural frequency of the corrugator roll.<BR>The evaluation of high-low corrugation aptitude for various corrugating medium becomes possible when evaluation system of high-low corrugation was estabished. It was found that physical properties of corrugating medium greatly influenced high-low corrugation. And further, caliper inversely related to the density of corrugating medium, and related to the thickness of it.

1 0 0 0 OA マグネタイトを利用したCO2の分解除去と燃料化

- 著者

- 玉浦 裕

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.45, no.5, pp.540-547, 1991-05-01 (Released:2009-11-19)

- 参考文献数

- 5

CO2 was decomposed completely (100%) at 290-350°C with the oxygen deficient magnetite which had been prepared by passing the H2 gas through the magnetite powder at 290-350°C. In this reaction, oxygen in CO2 is transferred into the spinel structure of the oxygen-deficient site, and carbon is deposited on the surface of the magnetite. The activation energy estimated from Arrhenius plot is 75.0 kJ. When the carbon deposited on the magnetite was reacted with H2O (400°C) and H2 (300-500°C), H2 and CH4 were generated, respectively. The reactions found in this study will open the door to construct the chemical heat pump which can be applied to the power station to reduce the CO2 emission.

- 著者

- 山崎 安彦

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.72, no.2, pp.182-186, 2018

<p>製紙工場内での保守・保全活動の一環で聴音検査というものがある。ステンレスの長い棒で回転機器のハウジングなどにあて,反対側に玉を溶接したものがあり,それを耳に当てて音を聞き回転体の状態を判断するというものだ。このときの判断は,測定者の経験がかぎになる。それを他の人々がシェアできない。IOT(モノインターネットInternet of Things)が求められている時代に入った今でも人による聴音確認で検査をされているのが製紙会社の現状である。</p><p>その聴音で確認されるの情報の中の「潤滑の状態」をいかに可視化するか,またその可視化されたものに対しての対応方法,すなわち改善の対策案などを有効に議論できるものにするかが重要になる。そこで今回はその「潤滑の状態」の音について取りあげる。</p>

- 著者

- 栗田 利雄 三橋 重信 金綱 久明 井口 正俊 代田 忠 トリフイジョ エレラ

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.36, no.2, pp.301-310, 1982

<I>Agave Tequilana</I> has been cultivated in Mexico for the manufacture of an alcoholic drinks well known as “Tequila”. For this purpose, the root stock of the plant is commercially used by cutting off leaves from the plant.<BR>In the course of “Tequila manufacture process”, a large quantity of fibrous residue is expelled out of the process as waste by pressing the cooked root stock. The leaves of the plant have not been utilized and left in the plantation as waste material.<BR>In this paper, both of the fibers obtained by decorticating from the leaves (sample A) and fibrous residue (sample B) were investigated for their pulping and paper-making properties, mainly on physical properties in relation to beating.<BR>From the results of this investgation, it was found that : <BR>(1) The fibrials in sample A showed parallel orientation to the fiber axis, and those in sam-ple B showed helical arrangement with respect to fiber axis.<BR>(2) The average length and width in fiber cells were in value of 1.7 mm, 10.3 um for sample A and 0.8 mm, 25.5 pm for sample B, respectively.<BR>(3) The fiber cell in sample A had a thicker cell wall and a narrower lumen compared with those in sample B.<BR>(4) sample A contained a very high quantity of soluble material in 1% NaOH solution, however, the contentes of total-cellulose, α-cellulose and lignin were in low value. In contrast, sample B contained high contents of total-cellulose, α-cellulose, pentsan and lignin.<BR>(5) Alkaline sulfite cooking process was applicable successfully to the both samples. But more rigorous condition was required in these samples than would be expected from the chemical constituents of both samples.<BR>(6) The pulp yield of sample A was very low compared with sample B. It was attributed to the low contents of total-cellulose and a-cellulose of raw material.<BR>(7) The brightness of pulp from sample B was low. It might suggest that some lignin remains in this pulp.<BR>(8) The water retention values and the bulk densities of the pulps from sample A increased rapidly on beating. It might suggest that an internal fibrillation in pulp fiber of sample A occurs more easily on beating.<BR>(9) The opacity of papers made from both samples decreased slowly on beating, and the tendency was not so remarkable. As a whole, these values remained at a high level compared with papers made from beaten conventional chemical wood pulps.<BR>(10) The breaking length, burst factor and tear factor of papers from sample A were in a high values than those of sample B. The breaking length and burst factor of papers from sample A were in comparable with papers made from beaten conventional chemical wood pulps, and the tear factors were superior to them.

1 0 0 0 においの知覚器官と環境行政動向

- 著者

- 富永 恭和

- 出版者

- 紙パルプ技術協会

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.63, no.12, pp.1459-1464, 2009-12-01

- 参考文献数

- 2

においは臭・匂と感覚の影響が大きく100人100様であり,色々な研究からも個人差の大きい器官を有している事が証明されている。<BR>近年,臭気苦情の発生は大きな様変わりを見せている。昭和40年代は畜産等第1次産業を中心に苦情の発生が多かったが,住宅地近辺からの移動により苦情は減少に転じた。そして第2次産業の公害対策(騒音・振動・水質等)が進むにつれ,臭気問題が表面化する。住民の移動(マンション・住宅街の造成)による工場周辺を囲むような街づくりが新たな苦情を起こしていることも要因の一つであると考える。第3次産業といわれるサービス業からの苦情対策は現状の悪臭防止法では追いきれない部分があり今後の課題になっている。<BR>本報では,嗅覚の仕組みと特性,悪臭防止法の制定から改正にいたる流れ,三点比較式臭袋法による臭気の数値化(臭気指数)とパネラー(三点比較式臭袋法被験者)選定による資格,更には紙パルプ及び他分野の発生臭気と対策,環境省の薦める感覚環境の街づくりといったにおいを利用した取組み等を報告する。