- 著者

- 田中 義信 井川 直哉

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.26, no.302, pp.149-154, 1960

The authors have made investigations about diamond wheel grinding in which plunge cut method by plain cup diamond wheels of bronze bonded was adopted. In this paper the influences of the diamond concentration of the wheel on stock removal is discussed theoretically and experimentally. And surface roughness produced in the grinding tests is also described.<BR>Theoretical investigation shows the tendency that stock removal decreases with the increase of the diamond concentration of the wheel if assumed the wheel having the abrasive grains whose tip has spherical shape, and the similar tendency was recognized in the grinding tests to some extent.<BR>Characteristics of the stock removal-normal grinding force (or contact pressure between the wheel and work surface) for a diamond wheel was clarified.<BR>It is also known that surface roughness <I>H</I><SUB>max</SUB> decreases with the increase of the diamond concentration of the wheel.

1 0 0 0 パイレツクスガラスの粗研削法の研究

- 著者

- 小林 昭 田中 一成

- 出版者

- The Japan Society for Precision Engineering

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.20, no.231, pp.208-216, 1954

- 被引用文献数

- 1

8. 1. 砥石の選択<BR>(1) 砥粒としてはGCが良い。<BR>8. 2. 研削条件の選定<BR>(1) 砥石の種類にかかわらず研削条件を変えれば正常研削範囲が存在する。<BR>(2) 鋼研削の場合に比べ,重研削が可能である。<BR>(3) 研削液は相当豊富に供給した方がよい。<BR>8. 3. 最適粗研削条件の目安<BR>表6に示すものである。<BR>8. 4. 久本の実験結果との比較(表6)<BR>3種のガラス(BK,F,S)の平面研削め実験から次の結論を得ている。<BR>(1) 溶融を起さないための切込限度を提案し,<BR>(イ) C砥粒の方がA砥粒よりも大きい。<BR>(ロ) 粒度の粗い方が大きい。<BR>(ハ) C砥粒の場合,結合度H,QよりもLの方が大きい。<BR>(ニ) 砥石周速の小さい方が大きい。<BR>(ホ) 砥石送り速度の小さい方が大きい。<BR>パイレツクスガラスの外周円筒研削では研制液が充分かゝるようにして研削すれば溶融摩耗を起さない。別に加工物を回転しないで砥石送りだけ与えて研削して平面研削に近づけて見ても溶融摩耗は起さなかつたので,パイレツクスガラスについては溶融摩耗を基にした切込限度による良否の判定は無意味と思われる。研削抵抗を基にした筆者の判定と比べ,(イ)(ロ)(ニ)は一致し,(ハ)については結合度により研削条件を変えれば,適正使用範囲が存在することが判り,(ホ)は逆で300φのガラスボビンについて砥石送り速度を小さくしたときにむしろ溶融摩耗を起すことがあつた。<BR>(2) 研削抵抗について砥石送り速度と切込み深さとの関係は,傾向としては一致している。<BR>(3) 比研削抵抗については前述したように疑問の点がある。

1 0 0 0 OA 4-6黄銅板の圧延による残留応力の測定

- 著者

- 浅枝 敏夫 西本 廉

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.24, no.279, pp.243-248, 1958-05-05 (Released:2009-06-30)

- 参考文献数

- 8

This paper describes how the magnitude and distribution of residual stresses in cold-rolled 4-6 brass sheets are affected by the reduction and the annealing temperature before rolling. For this purpose the residual stresses in the traverse direction as well as in the rolling direction are measured.The results obtained are summarized as follows :(1) The distributions of the residual stresses in the rolling direction are of the same type ; tension in the surface and compression in the inner layer.(2) The annealing temperature of 600°, 650° and 700°C causes nearly the same residual stresses in the rolling direction.(3) The residual stresses in the traverse direction are changed remarkably by the annealing temperature ; the stress caused by the rolling after annealing at 600°C is much greater than that at 650° and 700°C. And the type of stress distributions is oscillation type, in which compressive and tensile stresses exist alternately.(4) The rate of reduction is almost independent of the residual stresses in both directions.

1 0 0 0 OA 金属切削機構の力学的解析(第3報) 切削応力の解析

- 著者

- 谷口 和雄

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.29, no.338, pp.209-219, 1963-03-05 (Released:2010-02-16)

- 参考文献数

- 4

(1) The orthogonal machining tests on lead were performed at different cutting conditions to measure the horizontal and vertical components of the cutting forces.According as the increase of rake angles ranging from 20° to 40°, the shear strain at a shear plane and the horizontal component of cutting force decreased, but the shear stress at a shear plane increased a little.According as the increase of cutting velocities ranging from 50 to 4, 000 mm/min, the shear strains varied very little, but the shear stresses increased some amount. These effects of cutting velocities were considered that the higher the cutting velocities, the greater the strain rates which accompanied strain hardening.(2) The angle between the cutting force and the direction of cutting, φR was expressed as follows.tan φR=Ft/Fc;φR=βf-α.The relation of shear angle φs with φR was expressed as φs+φR= 45° according to Leeshaffer, that is, φs=45°-βf+α, but the experimental results for lead revealed φs+φR<45°, and φo+φR_??_45°.φo is an ideal shear angle which was explained in Report 1.(3) The contact length of tool-chip was considered a very important factor to determine the shear strain and the shear stress of a chip at the rake surface of a tool.The contact length was measured experimentally by the observations of the wear land on the rake surface. On the other hand, the contact length was calculated theorically for the complex model of chip formation.The experimental value of the contact length was larger than the theoritical one which was used to determine the strain and stress of a chip at the rake surface in this report.(4) The equilibrium equation was treated between input energy and output energy for the orthogonal cutting system which contained material, a chip and a tool.Being based on the equilibrium equation, the cutting energy was analized mathematically for the complex model of chip formation which was explained in Report 1.(5) It was assumed that the cutting energy could be divided in some factors independently to each other, and that it was replaced by one shear strain and one shear stress.The assumptions are shown as follows :Wc{1-E(ω)/Wc}=τ1·γ1+τ2·γ2+τf·γfγt=γ1+γ2+γfτt=Wc/γt{1-E(ω)/Wc}_??_Wc/γtIn this report the relations of Wc(τ1·γ1+τ2·γ2+τf·γf) and γtτt, were checked experimentally for lead.

- 著者

- 清水 浩

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.51, no.2, pp.290-293, 1985

かつて,レーザプレイボーイ説ということが関係者の間でささやかれた時期があった.レーザは研究に大きな費用を要する割に,応用上の成果が生まれにくいという意味である.これは,レーザの実験室レベルの研究成果にたいして,工業的に使用できるレーザの開発が追いつかなかったことが最大の原因であったと考えられる.ところが,基礎的技術が進んだことにより,最近になって,レーザは,微細加工に,光通信に,医学にと,どんどん応用分野を広げている.<BR>レーザレーダも,この恩恵をこうむり,このごろやっと実用の域に達しつつあるというのが,15年間この分野にたずさわってきた私の実感である.今後は,レーザレーダによる全国の環境や気象のモニタリング網の開発や,スペースシャトル等宇宙からの計測などの応用分野の開発に向けて研究が進むものと期待している.

1 0 0 0 OA 電池の小型化と軽量化

- 著者

- 杉本 幸一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.44, no.517, pp.82-86, 1978-01-05 (Released:2010-02-16)

- 参考文献数

- 4

1 0 0 0 OA 切りくず形状の幾何学 切りくず形状の研究(第1報)

- 著者

- 中山 一雄

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.38, no.450, pp.592-598, 1972-07-05 (Released:2010-02-16)

- 参考文献数

- 9

- 被引用文献数

- 1

以上で切りくずがとるらせんの形状と位置に関するすべての情報がただ三つの量によって一義的にきまることが示された.すなわち,たとえば流出角η,上向きおよび横向きカールの曲率半径ρxとρzの3者が与えられれば,らせんの半径ρとピッチp,およびらせんの軸の傾角θとx-z面からの距離eが上記諸式で与えられる.ただし以上は切りくず分離線を基準にして表示したものであり,実際には切れ刃に対する位置が問題になるので,さらに切りくず-すくい面接触長さと分離線傾角ψを知る必要がある.前者はあまり問題にならないが,ψは高送り切削ではかなり大きくなり,切りくずの折れやすさに影響する.

1 0 0 0 OA 機械要素専門委員会報告/軸受及び潤滑専門委員会報告

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.25, no.290, pp.130-162, 1959-03-05 (Released:2009-06-30)

1 0 0 0 OA 精密旋削面の虹むら

- 著者

- 藤本 定正

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.491, pp.1117-1121, 1975-12-05 (Released:2009-06-30)

- 参考文献数

- 6

The iridescent unevenness of a precisely turned surface is investigated by a ray-tracing procedure with reference to the pitch unevenness of turned grooves. The surface is illuminated at an oblique angle with a linear light source which is crossed at right angles to the cylindrical axis of the surface, and the image of the light source focussed by the surface is observed in the direction of diffraction. The image is smooth parabolic when no pitch unevenness is present on the surface. The image calculated on the assumption of sinusoidal pitch unevenness arises disturbance of the image corresponding to the change of pitch. When the surface is illuminated with a white light source, this disturbance turns into iridescent unevenness. A surface having sinusoidal unevenness of pitch is worked by a lathe provided with a periodically variable feed device connected to the tool slide, and the theoretical result is confirmed. The pitch unevenness tolerable in the existence of iridescent unevenness differs depending to the intensity of iridescence on the surface.

1 0 0 0 OA 工作機械の技術提携

- 著者

- 岡崎 松三

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.29, no.342, pp.485-491, 1963-07-05 (Released:2009-06-30)

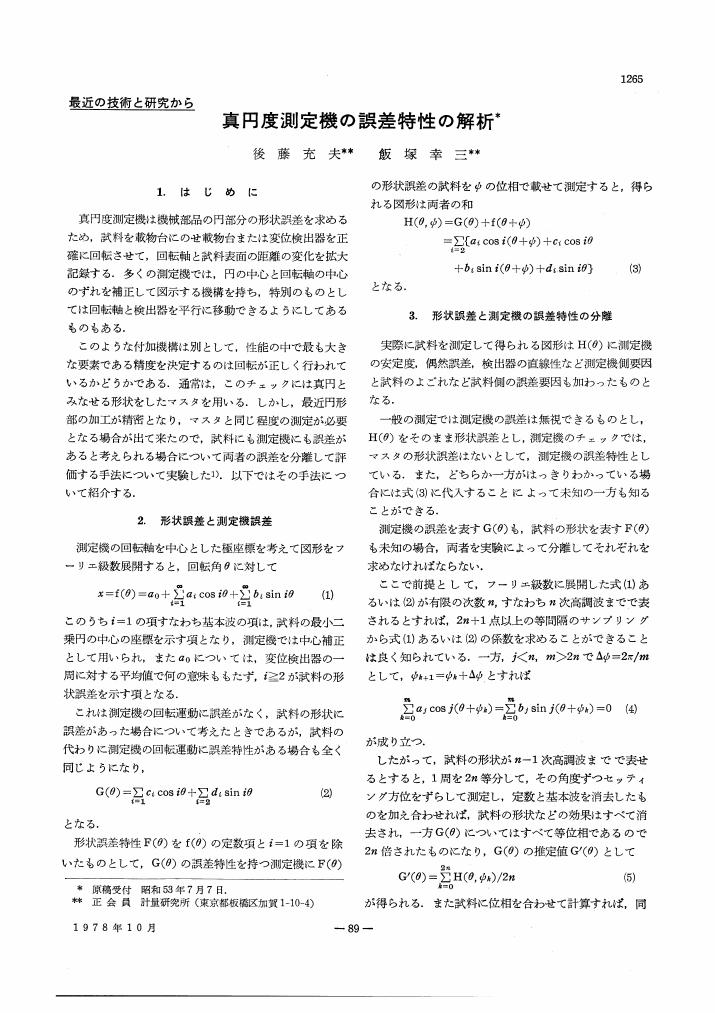

1 0 0 0 OA 真円度測定機の誤差特性の解析

- 著者

- 後藤 充夫 飯塚 幸三

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.44, no.526, pp.1265-1267, 1978 (Released:2009-06-30)

- 参考文献数

- 1

- 被引用文献数

- 1 1

1 0 0 0 OA 超精密加工技術 歴史的発展と今後への期待

- 著者

- 小林 昭

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.50, no.2, pp.347-356, 1984-02-05 (Released:2010-02-16)

- 参考文献数

- 38

1 0 0 0 OA くさび・円筒押込みにおける内部応力分布の解析

- 著者

- 神宮 利夫

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.482, pp.280-286, 1975-03-05 (Released:2009-06-30)

- 参考文献数

- 3

It has been experimentally suggested that the plastic deformation beneath any indenter is similar in pattern to the stress distribution obtained by the theoretical elastic analysis. When it is attempted to theoretically analyze the stress distribution beneath the wedge and the circular cylinder indenters, it is seen that the discontinuity occurs in the process of analysis. But, the logical development is revived the validity by introducing the result of rectangular block into the analysis. This paper is to be said that such an approach is useful for the stress analysis of two dimensional indentation.

1 0 0 0 有機機能材料

- 著者

- 斎藤 省吾

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.46, no.6, pp.715-720, 1980

1 0 0 0 星形車切削用ホブ歯形について

- 著者

- 森田 鈞

- 出版者

- The Japan Society for Precision Engineering

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.23, no.273, pp.524-528, 1957

In this study star-shaped wheel means the wheel with triangular teeth. The object of this study is to decide the positions of the pitch circle to generate the hob profiles for cutting starshaped wheels. By calculation the envelope of the teeth of wheel on rack which makes rolling contact with the pitch circle of the wheel was obtained, and under the condition in which the envelope can exist the allowable range of the position of the pitch circle was decided.<BR>The graph showing the relation among tooth angle, number of teeth, root circle radius and pitch circle radius of the wheel was drawn to faciliate to decide the position of the pitch circle.

1 0 0 0 レーダを用いる動物

- 著者

- 下沢 楯夫

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.47, no.9, pp.1088-1095, 1981

1 0 0 0 OA シンクロトロン放射光とX線リソグラフィ

- 著者

- 鳳 紘一郎

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.50, no.11, pp.1741-1746, 1984-11-05 (Released:2009-06-30)

- 参考文献数

- 14

1 0 0 0 OA データ処理装置用入出力装置

- 著者

- 岩井 麟三

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.32, no.375, pp.247-256, 1966-04-05 (Released:2009-06-30)

1 0 0 0 OA 銅およびアルミニウムの真空中の切削挙動

- 著者

- 上原 邦雄 檀原 袈裟男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.490, pp.1043-1049, 1975-11-05 (Released:2009-06-30)

- 参考文献数

- 9

This paper deals the cutting behavior of copper and aluminum in vacuum machining in which the materials were turned by specially made lathe at 40 m/min of cutting speed and under the reduction of pressure up to 10-4 mmHg. It was found that the cutting characteristics such as cutting force, cutting ratio etc. are not influenced by the degree of vacuum in machining tough pitch copper, oxygen free copper and 98% aluminum, however, they are affected in machining high purity aluminum. This is a contrasting result compared with the former paper in which the cutting behavior of carbon steel and titanium was examined. In order to clarify the cause of above phenomena, the experimental data were examined in detail basing on five factors which would affect the state of cutting in vacuum machining. As the result, it is cleared that the constancy of the cutting force in machining tough pitch copper and oxygen free copper is due to the nearly equal shear strength of adsorption layer or oxide film at the tool-chip interface compared with that of metallic contact part of the interface. Further, it is concluded that the cutting behavior of aluminum is affected strongly by the existence or the formation of γ alumina at tool-chip interface.

1 0 0 0 OA 磁気浮上車の研究開発の現状

- 著者

- 山村 昌

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.45, no.533, pp.626-631, 1979-05-05 (Released:2009-06-30)

- 参考文献数

- 7

- 被引用文献数

- 1 1