- 著者

- 岡本 強一 遠山 岳史

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会講演会論文集 22 (ISSN:24241628)

- 巻号頁・発行日

- pp.247-249, 2016-05-26 (Released:2019-09-28)

1 0 0 0 OA 船舶建造工程シミュレーションを用いた生産計画立案手法の現場適用に関する研究

- 著者

- 大久保 友結 満行 泰河

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会論文集 (ISSN:18803717)

- 巻号頁・発行日

- vol.37, pp.115-123, 2023 (Released:2023-08-03)

- 参考文献数

- 18

Shipbuilding is one of the most complex production systems in the manufacturing industry because of the incredible variety of parts and highly complex processes. However, production plans are currently prepared manually depending on the experience of expert workers. In this paper, a production planning method based on shipbuilding process simulation is proposed for use in actual shipyards, which simultaneously satisfies the needs of both production managers, who require on-time delivery plans, and field workers, who aim to minimize waiting time and improve operating rates. Specifically, the authors developed a hybrid method that combines backward and forward simulation for planning front-loading to meet deadlines and reduce waiting time. In the case study, the method was applied to a sub assembly conveyor line in an actual shipyard to demonstrate the validity and feasibility of the simulation results.

1 0 0 0 OA 世界最大船型のRO/RO船"TONSBERG"(<シリーズ>新造船紹介SOY2011)

- 著者

- 江熊 寿典

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.43, pp.47-49, 2012-07-10 (Released:2018-02-24)

1 0 0 0 OA 実船の操縦性能推定法に関する研究

- 著者

- 青木 伊知郎 貴島 勝郎 古川 芳孝 名切 恭昭

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会論文集 (ISSN:18803717)

- 巻号頁・発行日

- vol.3, pp.157-165, 2006 (Released:2006-12-26)

- 参考文献数

- 9

- 被引用文献数

- 5 4

Since International Maritime Organization (IMO) has adopted "The Standards of Ship Maneuverability" as IMO Resolution MSC.137(76), the ship maneuverability is evaluated under this standard. Therefore, we have to know the accurate ship maneuvering characteristics at the design stage, especially the initial design stage. On the prediction method of ship maneuverability, there are many papers for estimating method of the maneuverability of a ship based on the model test, but there are few papers for predicting the maneuverability of a full-scale ship practically. The authors have already proposed the simple, accurate and practical prediction method for the ship maneuverability of model ship. So, we need to develop the practical prediction method for ship maneuverability of a full-scale ship in the deep water. In this paper, we propose the approximate formula of the interaction coefficient, γ and ωR0, obtained by comparing the predicted maneuvering motion with the measured results of the sea trial for twelve full-scale ships. We confirm the effectiveness of the practical prediction method using the approximate formula of the interaction coefficient for ship maneuverability of a full-scale ship. Though this approach must be validated in many kinds of ship as the next step, it will be expected that this method is very useful for predicting ship maneuvering characteristics at design stage on conventional ship.

1 0 0 0 OA 列車酔いに影響する振動成分とその評価法

- 著者

- 鈴木 浩明 大野 央人

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.69, pp.29-32, 2016-11-10 (Released:2022-10-28)

- 参考文献数

- 7

1 0 0 0 OA CFRP製プロペラの研究開発

- 著者

- 山磨 敏夫 櫻井 貴哉

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.86, pp.7-13, 2019-09-10 (Released:2023-01-25)

- 参考文献数

- 9

1 0 0 0 OA 深海潜水調査船しんかい6500の耐圧殻の設計・製作

- 著者

- 高川 真一 森鼻 英征 下田 廣一郎 山内 裕 神野藤 保夫 井上 和也

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 関西造船協会誌 214 (ISSN:03899101)

- 巻号頁・発行日

- pp.177-185, 1990-09-25 (Released:2018-04-01)

The pressure hull of deep submergence research vehicle is an utmost important structure that secures the safety of crew members against the hydrostatic pressure in deep sea, and should be as compact in size and light in weight as possible in order to obtain easy operation and high maneuverability of the vehicle. In design and fabrication of the pressure hull, the application of high strength material which has reliable characteristic for practical use, of design method suitable for such material and fabrication procedure which satisfies the quality requirement of the highest degree have been encouraged. In the develoment of the 6500m deep submergence research vehicle "SHINKAI 6500", which is the latest submergence research vehicle following the 2000m deep submergence research vehicle "SHINKAI 2000" in Japan, the investigation in various fields was carried out in order to adopt titanium alloy, which has superior strength/weight ratio, for the pressure hull. The production procedure of heavy thickness and large size plate and forging material, and the fabrication procedure of the pressure hull were investigated by the fabrication of the full scale model made of titanium alloy and by material tests with specimens cut from the model. The collapse behaviour was examined by collapse tests using scale models of titanium alloy and by nonlinear behaviour analysis with FEM procedure. Finally, in order to confirm both the fabrication procedure and design method in total, the cyclic loading test and collapse test using scale model fabricated according to the procedure equivalent to that for the actual pressure hull. This paper presents the design and fabrication of the pressure hull of "SHINKAI 6500".

- 著者

- 佐藤 千昭 川村 昭宣

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.841, pp.512-529, 1999-07-25 (Released:2018-03-28)

1 0 0 0 OA 浮体型振り子式波力発電装置の研究(第一報) -規則波中発電特性試験-

- 著者

- 豊田 和隆 永田 修一 今井 康貴 瀬戸口 俊明 小野 圭介

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会論文集 (ISSN:18803717)

- 巻号頁・発行日

- vol.13, pp.67-74, 2011 (Released:2011-09-08)

- 参考文献数

- 7

- 被引用文献数

- 2 1

Fixed type pendulum wave energy converter is a kind of movable body type wave energy converter and it was invented by Kondo with Muroran Institute of Technology in Japan. Some researches on this device were carried out experimentally and theoretically, and its high energy conversion efficiency was shown. However, this device was not practical used yet, because the initial cost is so expensive as it needs heavy construction in the sea. And also, it is difficult to keep it safety under the critical weather condition like a typhoon is another main reason. So, as a solution strategy for above problems,Furusawa proposed the uplifting type pendulum wave energy converter. Furthermore Watabe proposed the floating type pendulum wave energy converter (FPWEC) which is moored to the seabed with some lines as another solution. Changing from fixed type device to floating type device, we can expect the reduction of initial costs and emergency measures. Watabe carried out some research on FPWEC, but it is not enough to say that the design method for this device was established.In this paper, we have made a test model of FPWEC for tank test and some tests were carried out as a first step of development for this device.To estimate the performance of this device, we have measured power output and body motion in regular waves.

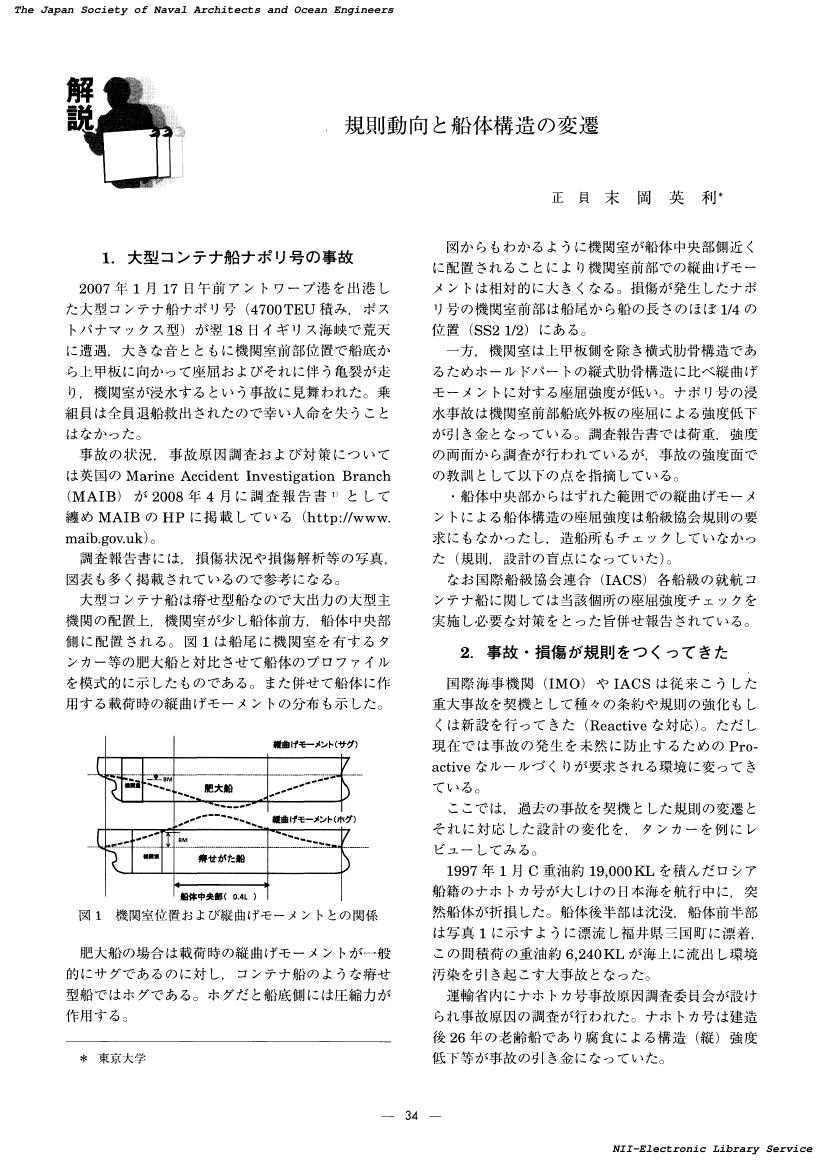

1 0 0 0 OA 規則動向と船体構造の変遷

- 著者

- 末岡 英利

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.20, pp.34-38, 2008-09-10 (Released:2018-03-30)

1 0 0 0 OA 16世紀17世紀の帆船 : 慶長派遣欧使節船の復元に因んで

- 著者

- 寳田 直之助

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.778, pp.20-28, 1994 (Released:2018-02-25)

- 参考文献数

- 24

1 0 0 0 OA スーパーエコシップ(SES)の普及促進に関する鉄道・運輸機構の取組み

- 著者

- 西川 康士

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.66, pp.7-12, 2016-05-10 (Released:2017-01-26)

- 参考文献数

- 1

1 0 0 0 OA 「マスカー,プレリー」

- 著者

- 北島 郁夫

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本造船学会誌 (ISSN:03861597)

- 巻号頁・発行日

- vol.728, pp.125, 1990-02-25 (Released:2018-04-05)

1 0 0 0 OA 第4回 係留索の切断事故と係留問題

- 著者

- 山本 一誠

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会誌 KANRIN(咸臨) (ISSN:18803725)

- 巻号頁・発行日

- vol.81, pp.51-56, 2018-11-10 (Released:2023-01-06)

- 参考文献数

- 17

1 0 0 0 OA 翼付双胴高速船SUPERJET-30"瑞光"

- 著者

- 日立造船株式会社船舶・防衛事業本部

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- らん:纜 (ISSN:09160981)

- 巻号頁・発行日

- vol.28, pp.22-23, 1995-06-30 (Released:2018-02-25)

1 0 0 0 OA 1 操縦運動シミュレーションの数学モデル(<特集>操縦性)

- 著者

- 貴島 勝郎 古川 芳孝

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.869, pp.553-556, 2002-09-10 (Released:2018-03-28)

- 参考文献数

- 7

1 0 0 0 OA 貨客船浮島丸について

- 著者

- 関西汽船株式会社工務部

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 関西造船協会誌 98 (ISSN:03899101)

- 巻号頁・発行日

- pp.39-45, 1960-08-20 (Released:2018-02-24)

1 0 0 0 OA 2020S-OS3-1 鄭和西洋下りの宝船に関する一考察

- 著者

- 小嶋 良一

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- 日本船舶海洋工学会講演会論文集 30 (ISSN:24241628)

- 巻号頁・発行日

- pp.69-72, 2020 (Released:2023-03-18)

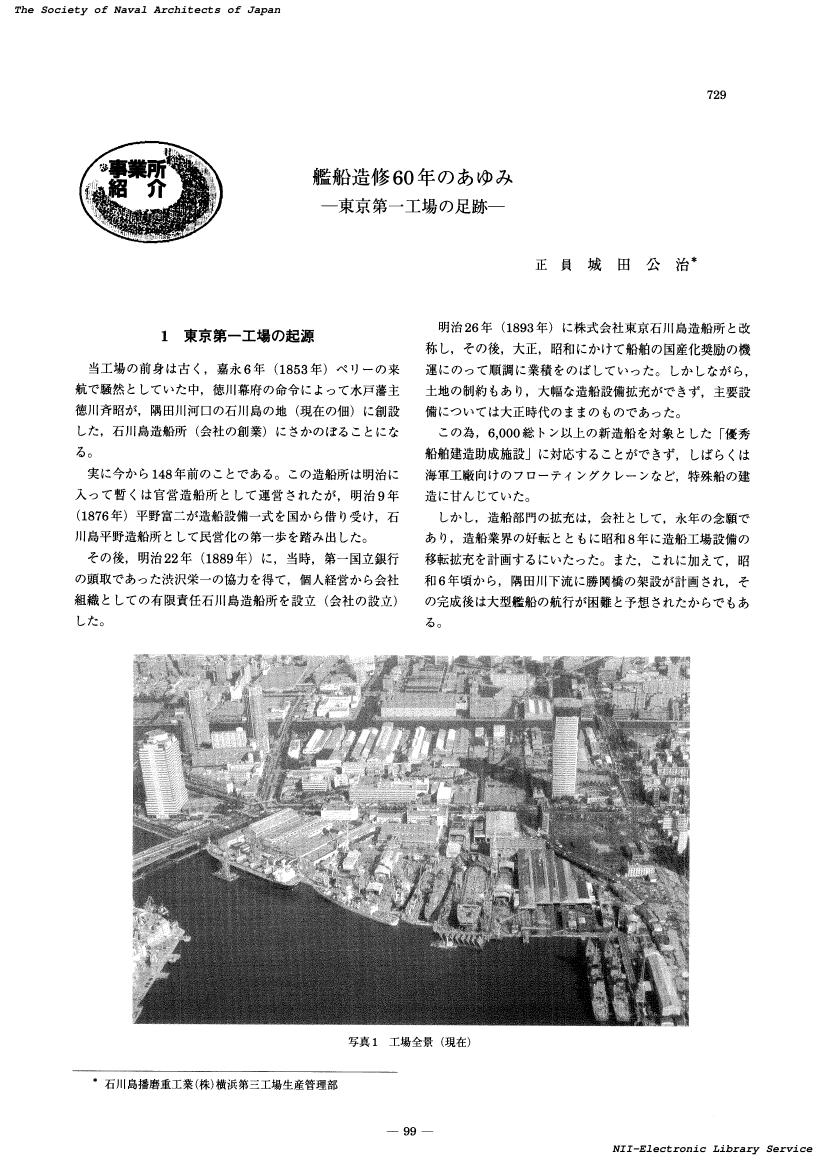

1 0 0 0 OA 艦船造修60年のあゆみ : 東京第一工場の足跡

- 著者

- 城田 公治

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.864, pp.99-103, 2001-11-10 (Released:2018-03-28)

1 0 0 0 OA 船舶流体力学小史 : (その10)

- 著者

- 池畑 光尚

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.865, pp.62-68, 2002-01-10 (Released:2018-03-28)

- 参考文献数

- 7