2 0 0 0 OA 熔銑爐操業に於ける低炭素セミスチール製造に關する基本的研究(第 2 報)(I)

- 著者

- 堀切 政康

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.16, no.9, pp.935-960, 1930-09-25

The present author investigated the improvements of physical and mechanical properties of cast iron from a practical foundry work and attained to the next conclusions : -The properties of cast iron vary with the cupola melting conditions remarkably, consequently, if we want to produce a high quality cast iron, it is necessary to get a suitable melting condition, say, high and slow melting for the first time. And also if we want to get a high quality cast iron, it is necessary to lowering the total carbon content of cast iron, according to the rate of cooling for the purpose of producing a cast iron with a uniform and an excellent mechanical property. But the lowering of carbon content necessitates an addition of a resultant amount of Silicon, if we want to produce a sound casting with uniform structures. Thus it is presumed that there is a relation between the total C%+Si%, and the size of casting on the condition of a reasonable melting. By these conclusions, the present author produced high grade cast irons (T.C 2.5%∿2.8%, Si 3.0%∿2.0%, Mn 1.0%∿2.0%, P, S trace) for the large and complex cast iron by the cupola direct melting Semi-Steels. But in the cupola melting, if we want to produce a low carbon Semi-Steels it is necessary to determine the cupola conditions for the restriction of carbon absorption and high temperature melting. For these Purposes, the present author already investigated the whole conditions for a cupola melting by the aid of small cupola. Its contents are as follows : - 1 tuyere problems 2 blast volume problems 3 on the effects of carboneous matter 4 on the condition of cupola melting zone 5 on the depth of cupola hearth. 6 on the relations between the combustion gas (CO_2 CO O_2) and the change of cupola operation, etc. After that the present author continued the same investigations on a large cupola and attained to the same conclusions, so that in this paper, he wants to make public these results, that is, the whole conditions for the mode of production of low carbon Semi-Steels by a large cupola melting.

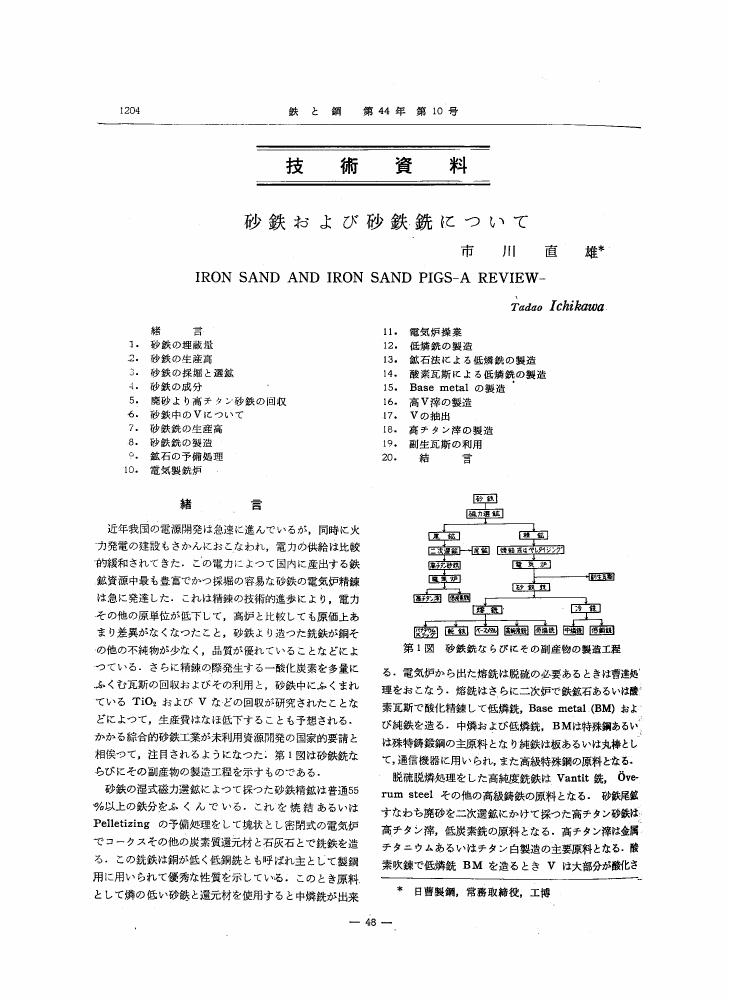

2 0 0 0 OA 砂鉄および砂鉄銑について

- 著者

- 市川 直雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.44, no.10, pp.1204-1216, 1958-10-01 (Released:2009-05-26)

2 0 0 0 OA 日本刀の研磨法に就き

- 著者

- 俵 國一 本間 清人

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.6, no.2, pp.171-189, 1920-02-25 (Released:2009-07-09)

2 0 0 0 OA 製鋼スラグを利用した藻場再生技術における腐植物質の鉄溶出への影響

- 著者

- 山本 光夫 福嶋 正巳 劉 丹

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.97, no.3, pp.159-164, 2011-03-01 (Released:2011-03-01)

- 参考文献数

- 16

- 被引用文献数

- 16 17

Barren grounds in coastal area are serious problems in Japan and throughout the world. Although several factors have been proposed to account for barren grounds, we have especially focused on lack of dissolved iron for restoring seaweed beds. It has been developed a method that the mixture of steelmaking slag and humus materials, such as composts, were supplied in seawater. A concentration of dissolved iron can be increased by using the method, since complexes, iron-humates, are produced from iron in steelmaking slag and humic substances in compost. In this study, we evaluated the effect of humic substances in this method for increasing dissolved iron concentration. A laboratorial iron elution test by using actual seawaters was attempted. Three kinds of samples for iron elution, only steelmaking slag, only humus materials, and a mixture of steelmaking slag and humus materials, were prepared. The change of iron concentration in each small tank had been monitored. We found that iron elution rate in the case of the mixture of steelmaking slag and compost was faster than that in the case of only steelmaking slag. Furthermore, it was expected that the characteristic of the structure of humic substances were related to increase iron elution from steelmaking slag. The mixture of steelmaking slag and humus materials was more effective not only for increasing iron concentration in seawater and but also for extending the life time of Fe elution.

2 0 0 0 OA 鋼材の火花試驗に關する研究(II)

- 著者

- 三島 徳七 三橋 鐵太郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.28, no.9, pp.959-968, 1942-09-25 (Released:2009-07-09)

- 参考文献数

- 2

Die Untersuchungen erstreckten sick auf C-Stähle, Cr-Stähle, Cr-Ni-Stähle, Cr-Mo-Stähle, die in Form von geschmiedeten and gegossenen Rundstangen sind. Versuche uber den Einfluss von Schmieden auf Funkbarkeit von C-Stähle. Versuche uber den Einfluss allerleien Warmebehandlungen auf Funkbarkeit von Ni-Cr-Stäble. Versuche über die Wirkung des Cr-, Mooder Ni-gehaltes auf Funkbarkeit der C-Stähle.

2 0 0 0 連続鋳造機鋳型内の溶鋼流動制御技術の変遷(鋳造・凝固)

- 著者

- 高谷 幸司

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.90, no.10, pp.751-757, 2004-10-01

- 参考文献数

- 41

- 被引用文献数

- 8

電磁撹〓と電磁ブレーキは,その基本的な動作として,電磁撹〓は能動的で流動促進作用,電磁ブレーキは受動的で流動抑制作用を特徴とするが,両者ともに近年の連続鋳造設備の多くに設置され,高生産性かつ高品質の鋳片製造に効果を発揮している。その選択は状況次第であるが,その動作特性から考えて,薄スラブマシンに代表されるより高速な連続鋳造の実現には電磁ブレーキ,表面品質が問題となる比較的低速なマシンにはメニスカス電磁撹〓の採用が適切な選択と考えられる。また,浸漬ノズルの形状についても,今なお多くの改善が継続されており,ノズル閉塞防止技術と併せて今後の進展が期待される。さらに,今後の技術として軟接触鋳造の商用化に期待がかかるものの解決すべき課題は多い。<BR>適切な流動制御を行うには,磁場の効果を含めて,鋳型内の流動・伝熱現象と鋳片に発生する種々の欠陥との定量的関係のさらなる解明が必要である。複雑な現象の解明と新たなアイデアで,更なる高生産性かつ高品質な鋳片製造技術が確立されることを願ってやまない。

2 0 0 0 OA 特種鋼材の二三の性質に就て

- 著者

- 佐々川 清

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.15, no.3, pp.201-224, 1929-03-25 (Released:2009-07-09)

According to the industrial progress, it is evident that the demand is going up to get large steel mass having the great stiffness and toughness. This problem will be solved by using some alloy steels in spite of plain carbon steel. To have good alloy steel it is necessary that the large mass is thoroughly uniform.Some special properties of alloy steels are investigated and described here.1) Mass effect;: -Steels used are plain C-steel, Ni-steel, Cr-steel, Ni-Cr-steel, Ni-Cr-mo steel, long rods of various diameters are forged from ingots, Annealed and quenched in water and in oil from hardening temperature. Hardeness change through the sectional area is measured, Theoretical interpretation is made on the phenomene of mass effect, concerning to the chemical composition, cooling velocity and the mass, 2) Residual stresss due to heat treatment;: -Several methods to measure the internal stress are described, Some experiments are made to research the residual stress due to heat treatment in using large mass of alloy steels, Some methods to eliminate the residual stress are discussed, 3) Temper-brittleness;: -The phenomene of temper-brittleness is described, To ascertain the relation between the temper-brittleness and tempering temperature, some experiments are made, Conclusion;: -To have good alloy steels of large mass, it is necessary to select the steel without or least mass effect. To avoid the effect of residual stress due to tempering, it must be reheated to a high temperature for some hours, but the temperature must be selected that no temper-brittleness well occur.

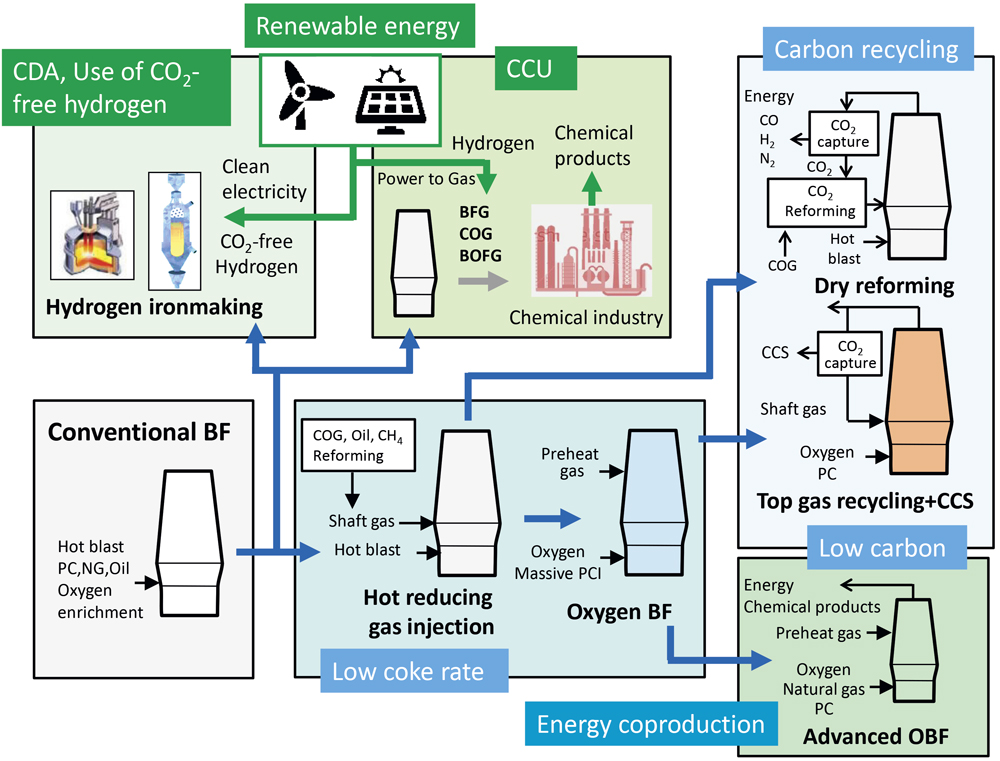

2 0 0 0 OA 鉄鋼における二酸化炭素削減長期目標達成に向けた技術展望

- 著者

- 有山 達郎

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.6, pp.567-586, 2019 (Released:2019-05-31)

- 参考文献数

- 81

- 被引用文献数

- 4 16

Global warming has been regarded as a crucial issue in every industry. Since long term global goal was set on the basis of Paris Agreement, a considerable evolution toward CO2 mitigation in 2050 is desired even in steel industry. Until now, many various technology developments were carried out in the ironmaking area; however, the innovative progress beyond the past progressive developments is required to attain the long-term goal in 2050. This review focuses on the current technology development on CO2 mitigation to date and the design of an ambitious ironmaking process for the future. In particular, the directions for low carbon and decarbonization are discussed from the viewpoints of technological aspects and the comprehensive consistency with sustainability in steel industry. Moreover, the perspectives on CCU (CO2 Capture and Utilization) and hydrogen ironmaking process based on the renewable energy aiming for carbon direct avoidance are described.

2 0 0 0 OA 歐洲に於ける熔鑛爐の酸性操業に就て

- 著者

- 嘉村 平八

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.25, no.7, pp.535-543, 1939-07-25

In this paper, the recent development of acid smelting of the blast furnace is discussed. The working results with acid slag at the Corby Works in England and the Gutehof-fnungshutte in Germany are briefly described. In the Corby works, it has been previously very difficult to smelt Northamptonshire ore for the manufacture of basic pig iron for steel making purposes, on account of the high proportion of alumina to silica. The difficulties encountered with high alumina slag has been successfully overcome with the basicity ratio of about 0.93 in the slag, which is the ratio of lime to silica for obtaining a minimum melting point and a minimum viscosity. In the Gutehoffnungshutte, the idea is to reduce the amount of slag produced and the quantity of coke consumed in the smelting of low grade German ore for the production of basic bessemer pig iron with acid slag which has the basicity ratio 0.8. It is an unsuitable and inefficient method for the elimination of sulphur, and no attention is paid to the sulphur content of the pig iron. The sulphur is removed by subsequent treatment with soda.

2 0 0 0 OA 橋梁における高力ボルトの遅れ破壊

- 著者

- 松山 晋作

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.8, pp.903-912, 1983-06-01 (Released:2009-06-30)

- 参考文献数

- 16

- 被引用文献数

- 6 8

実橋における高力ボルトの遅れ破壊に関する事例解析結果をまとめると次のようになる.1) 橋梁の桁構造別にみると箱桁における損傷例が多かつた.これは桁内部に水が溜まるために日照時には高温高湿条件となり腐食反応が生じやすいためである.したがつて,箱桁には水抜き孔を設けて桁内部が乾燥状態を保つようにすることが破損防止上必要である.2) 橋梁によつて破損が上フランジ,ウェブ,下フランジなどのある箇所に集中する傾向が認められた.この原因は明らかではないが,ボルトの遊びねじ長さ,水滴の溜まりやすさ,温度上昇度など,ボルトの製造ロット別に生ずる材質的差異以外の要因が考えられる.3) ボルトの破断部位は不完全ねじ部が一般的には多いが,橋梁によつては首下破断が多発する場合もあつた.規格上は首下はねじ部より強い筈であるから,首下破断を生ずる理由には,第一に頭が下向きの場合首下に水滴が溜まりやすいこと,第二に首下の丸み部に座金の角があたり荷重が集中したことが考えられる.とくに後者の場合には座金が遅れ破壊してボルト孔内部への水の浸入を容易にすることもある10)ので,座金の内側隅は十分面とりする必要がある.4) F 13T (No.4)を適用した唯一の橋梁で約15年間にわたりボルトの破損傾向を追跡調査した.その結果ボルト破損の確率分布は二母数ワイブル分布に従うことが認められた.継手のすべりに対する安全率を考えると,破損の補修をしなかつた場合にはこの橋梁は約40年で変状を生ずると推定された.5) F 11Tを使用した橋梁で最初の破損を生ずるまでの寿命分布も二母数ワイブル分布で表され,故障率が時間と共に低下する傾向を示した。現在F 11Tの使用は中止されているから,すでにF 11Tを使用している既設の橋梁での遅れ破壊事例は今後減少傾向にあると推定される.6) 高力ボルトを適用した初期の橋梁や遅れ破壊を発生した橋梁についてボルトを採取して軸部の鉄さびの分析を行つた.直接雨に曝された箇所や箱桁ではボルトが湿つた状態にあるものが多かつたが,鉄さびの組成からも水の存在が認められた.遅れ破壊は水の存在下で腐食反応の結果生ずる水素により誘起されるもので,乾燥状態で使用されていれば遅れ破壊は生じない.7) 破面の破壊起点部には旧オーステナイト粒界割れがみられた.材料によつては破壊途中で圧延方向にミクロ偏析帯に沿つて粒界割れを生ずる縦割れが認められた.8) 遅れ破壊を生じたボルトの最小硬さはHRC 37.5であつた.従来の実験から得られた遅れ破壊を生ずる限界硬さはHRC 41であるから,HRC<41で破損したボルトは材質的鋭敏化原因があつたと考えられる.その原因として,浸炭による表面硬化, Pの粒界偏析, Bの粒界における存在などが考えられた.これらの原因の検討から,熱処理炉の雰囲気は脱炭傾向にすること,可能な限り低燐の高純度鋼を用いること, B添加は必要最少量にすることなどが高力ボルトの信頼度を高めるために必要であると結論される.しかし市販鋼では高純化には限度があるから粒界炭化物が十分凝集するまで焼もどし温度を高めることが必要である.9) 一般に炭素量が多いと焼もどし軟化曲線の勾配が急になり,焼もどし温度変化の硬さへの影響が大きくなるから,炭素量の多い鋼種で高強度化するのは望ましいことではない.またバッチ型焼もどし炉のように装入方法によつては温度むらを生ずる場合には,一部に焼もどしが不十分で硬さの高い製品が混入する可能性があるので注意が必要である.

2 0 0 0 OA ボルトの遅れ破壊

- 著者

- 中里 福和

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.88, no.10, pp.606-611, 2002 (Released:2009-06-19)

- 参考文献数

- 54

- 被引用文献数

- 12 14

This review article on delayed fracture of bolts covers the following topics: general features of delayed fracture, case histories of in-service failures of high-strength bolts, existing demands for higher-strength bolts and their background, increasing needs for standardization of delayed fracture susceptibility evaluation method, and approaches so-far taken to prevent delayed fracture. The author emphasizes that, thanks to the recent intensive R&D activities, overcoming delayed fracture is now very close to the reality.

2 0 0 0 OA Cu含有ステンレス鋼の抗菌性

- 著者

- 鈴木 聡 宮楠 克久 佐藤 嘉洋 菊地 靖志 川上 洋司

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.8, pp.1021-1028, 2014 (Released:2014-07-31)

- 参考文献数

- 17

- 被引用文献数

- 2 4

Antimicrobial ability of Cu contained stainless steels was investigated. Antimicrobial ability increased with elute fraction of Cu ion from stainless steel surface into antimicrobial test medium. It is necessary to promote eluting fraction of Cu ion, that is, to achieve giving antimicrobial ability to Cu contained stainless steel that sub-micron order or larger size ε-Cu phases are dispersed in stainless steel, surface of stainless steel has high electrode potential and dissolved oxygen exist in the test medium.

2 0 0 0 OA たたら製鉄の炉内反応機構と操業技術

- 著者

- 永田 和宏 鈴木 卓夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.86, no.1, pp.64-71, 2000-01-01 (Released:2009-06-19)

- 参考文献数

- 8

- 被引用文献数

- 7 6

"Tatara" was a traditional box-type furnace in Japan and had produced steel and pig iron directly until 1923. After then, because of the low productivity, Tatara was not commercially operated but only for producing the materials of Japanese sword in little. In 1977 with the blank ages after the World War II, Japan Institute of Art Japanese Sword reconstructed the Tatara furnace, called "Nittoho Tatara". Then, Mr. Yoshizo Abe as a leader "Murage" realized his own technique for the Tatara operation because of the technique transfer only by oral instruction to the Murage's family. The 3rd Tatara operation in 1999 winter has been studied on the effect of fire flame (so called "Hose") and sound from furnace, the color and viscosity of slag (so called "Noro") flowed out from furnace and the condition of tuyers to the productivity of "Kera" including steel (so called "Tamahagane") and pig iron (so called "Zuku"), etc. This operation met the trouble of air blowing to the furnace in the final stage. Though many efforts had been made to recover the stable operation, the activity of furnace was stopped in shorter operation time than the other two operations. From the experiences of the recover, the fundamental treatments to make the operation stable have been cleared and also the reaction mechanisms to produce.

2 0 0 0 OA 自動車車体外板の樹脂化の動向

- 著者

- 井出 正 佐野 実 新井 重男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.72, no.11, pp.1674-1680, 1986-09-01 (Released:2010-02-15)

- 参考文献数

- 16

2 0 0 0 OA 希土類元素の選鉱と精製

- 著者

- 向井 滋

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.6, pp.633-644, 1985-04-01 (Released:2009-06-19)

- 参考文献数

- 18

- 被引用文献数

- 3

2 0 0 0 OA 支那事變に於ける日本刀の威力

- 著者

- 蒔田 宗次

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.24, no.12, pp.1106-1112, 1938-12-25

Participated in work of the party engaging specially in the repair of Japanese swords in the front, the author observed the superiority of Japanese swords in the light of the present Sino-Japanese fighting. It is a well-acknowledged fact that the Japanese sword has an excellent sharpness. Its splendid effect has invariably been shown in action at the present crisis, there being many instances to be quoted from numerous exploits in the actural occasions. A large number of Japanese swords being used in the front, sword makers are naturally very busy at present. We know the physical effect of the Japanese sword from its sharpness as well as the user's skill. Besides the most important matter is our strong faith for the Japanese sword. Consequentty, the mental effect of it against the enemy is very powerful with the action of the "Japanese spirit" in it. Therefore, we observe the Japanese sword not only materially but also spiritually. In short, the Japanese sword is considered to be a spiritual material, which stands to guard strongly and to prosper eternally the Land of Our Mikado.

2 0 0 0 OA ピアノ線製造法に関する研究

- 著者

- 虎岩 頼夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.29, no.7, pp.614-618, 1943-07-25 (Released:2009-07-09)

The author has experimentally manufactured various kinds of piano wire since Showa 15 (1940) from the necessity of the domestic manufacture of piano wire. In the present report, some properties of different kinds of domestic wire were compared with the imported products. It was confirmed that the quality as good as the imported products are now available in the wholly domestic wire, although more efforts are expected for the manufacture of better qualities. Above all, he mentioned of the brittleness appearing in the low-temperature heating and laid stress on its preventive methods. As the fundamental data, the result of the test on the effect of drawing speed, was described with special reference to the prospect of the X-ray study necessary therefor.

2 0 0 0 OA 鋼の加工熱処理の変遷と今後の動向

- 著者

- 牧 正志 古原 忠 辻 伸泰 森戸 茂一 宮本 吾郎 柴田 曉伸

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.9, pp.1062-1075, 2014 (Released:2014-08-31)

- 参考文献数

- 72

- 被引用文献数

- 24 30

After ausforming appeared as the first thermomechanical processing of steels in the first half of the 1960 s, various thermomechanical processings have been developed for the improvement of mechanical properties over the last fifty years. Their application was mainly to martensitic steels in the 1960 s such as ausforming and TRIP, and moved to ferrite (+ pearlite) structures by the development of controlled rolling and accelerated cooling of HSLA steels in the 1970~1980 s. However, recently, interest has returned to martensite (and also bainite) because of the demand for higher strength, and the ausforming and TRIP have been revived and successfully applied to commercial practice. Very recently, severe plastic deformation (SPD) is the focus of attention as a new method of producing a very fine-grained structure with grain size of less than 1 μm. By the application of SPD, dynamic phenomena such as dynamic recrystallization and dynamic ferrite transformation occur in the process. We need more systematic studies on such phenomena for the development of new type of thermomechanical processing in steels.

2 0 0 0 OA 連続溶融亜鉛メッキにおけるドロス生成反応について

- 著者

- 山口 洋 久松 敬弘

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.1, pp.96-103, 1974-01-01 (Released:2010-10-12)

- 参考文献数

- 12

- 被引用文献数

- 13 13

A study has been carried out on the dross formation in continuous galvanizing in relation to the aluminiumcontent in the bath.Iron and aluminium concentrations in drosses formed in conventional galvanizing lines are determined.In the laboratory, Zn alloys containing 0.22% Pb, 0.13-4.60% Al and 0.066-0.24% Fe are molten ingraphite crucibles and held at 465°C for 40hrs before cooling. Using the sectioned ingots, spectroscopic analysisof the portions free from dross and quantitative microscopy analysis of dross compounds are performed:On the basis of these results, the amount of dross and that of aluminium consumed in the dross formationreaction in conventional processes are estimated. Conclusions derived are as follows:Drosses contain two compounds, namely δ and Fe2Al5.When the aluminium content in the bath is in the range of 0.09-0.14%, δ and Fe2Al5 can coexist. Inthis case the higher the aluminium content, the lower the fraction of δ-compound. When the aluminiumcontent is higher than 0.15% the δ-compound can not be found.The amount of the bottom dross is estimated to decrease rapidly with increasing the aluminium contentin the bath up to 0.14% and becomes negligible above 0.15% Al. The amount of the top dross, however, increasesrapidly with increasing the aluminium content up to 0.14% and decreases gradually above 0.15% Al.The amount of aluminium consumed in the dross formation reaction is estimated proportional to the amount of iron dissolved from sheets.

2 0 0 0 OA 鋼の表面硬化法としての窒化

- 著者

- 高瀬 孝夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.9, pp.1423-1434, 1980-08-01 (Released:2009-06-19)

- 参考文献数

- 48

- 被引用文献数

- 10 16