3 0 0 0 OA 溶融亜鉛めっきスパングルの結晶方位および元素分布

- 著者

- 福居 康 甲田 満 広瀬 祐輔

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.77, no.7, pp.939-946, 1991-07-01 (Released:2009-06-19)

- 参考文献数

- 21

- 被引用文献数

- 5 5

Spangles formed at hot-dip galvanized steel were classified and the distribution of Pb and Al, which were impurity and additional element respectively in molten zinc bath, on the spangle surface was investigated. The hot-dip galvanized Al-killed steel was produced with gas reduction type hot dipping testing aparatus in which steel sheet was cleaned by heating in reducing atmosphere and dipped into molten zinc bath which contained 0.25 wt%Pb and 0.17 wt%Al. X-ray Laue method was used for determination of crystal orientation and EPMA was used for the measurement of distribution of Pb and Al at the spangles.The main results of the study are follows:(1) The spangles are classified from the point of view of the crystal orientation and the appearance into the seven types as follows, Fern I, Fern II, Mirror, Frost, Half fern, Feather, Triangle.(2) The direction of the straight boundary of the spangles coincide with the projected direction of preferred crystal growth orientation (<1010>) on the spangle surface.(3) Spangles are classified into α type and β type from the point of view of the inclination of c-axis (<0001>). The c-axis of α type spangle is inclined to the straight boundary of the spangles and the c-axis of β type spangle is inclined to the reverse direction.(4) The amounts of Pb and Al at the spangle surface vary with the types of the spangle.(5) The spangle with the larger amounts of Pb and Al has less brilliance.

3 0 0 0 OA 知っておきたい金属凝固の基礎(IV)

- 著者

- 郡司 好喜

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.7, pp.N371-N385, 1994-07-01 (Released:2009-06-19)

- 参考文献数

- 29

- 被引用文献数

- 1 3

3 0 0 0 OA 主要元素に基づいた古代遺跡出土鉄滓の識別

- 著者

- 松本 建速

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.55-61, 2005-01-01 (Released:2009-06-19)

- 参考文献数

- 14

To identify the process of iron production, some indicators are proposed by using the chemical components of excavated slag. Especially, the ratio of Ti/Fe and V/Fe are useful for this purpose. All indicators, however, are not always appropriate for the distinguishable procedure between bowl-shaped slag and other slag. It is not yet fundamentally explained that major elements of iron-making slag caused from any materials.In this article, ten major elements which are constituent of iron-making slag as Silicon (Si), Iron (Fe), Aluminium (Al), Titanium (Ti), Manganese (Mn), Magnesium (Mg), Calcium (Ca), Sodium (Na), Potassium (K) and Phosphorus (P) are considered by using the released analytical data. Every element has been normalized against Si, and the correlation diagrams are plotted. The correlation diagram with Si can be distinguished as 3 groups.( 1 ) Elements Al, Ca, Na, K and P have positive correlation with Si.( 2 ) Elements Ti, Mn, and Mg do not correlate with Si.( 3 ) Fe has negative correlation with Si.Elements of group (1) as Ca, Na, K and P increase the content in any slag during the smelting, refining and forging processes. Thus, it is obvious that these four elements can not be utilized for the distinguishable procedure of ancient iron-making slag.On the other hand, elements of group (2) as Ti, Mn and Mg are appropriate to be indicators for the distinguishable procedure of two types slag between forging slag (sometimes in refining process) and other slag (normally in smelting process). On the basis of concentration of the 3 elements, it is indicated that bowl-shaped slag is formed in forging (sometimes in refining), and other slag is done in smelting.As the result of this study, the ratio of element as Mn/Ti, Mn/Si, Mg/Ti and Mg/Si are suggested to be useful as indicators for the distinguishable procedure between bowl-shaped slag and other slag.

3 0 0 0 OA 薄板技術の100年 −自動車産業と共に歩んだ薄鋼板と製造技術−

- 著者

- 高橋 学

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.1, pp.82-93, 2014 (Released:2013-12-31)

- 参考文献数

- 74

- 被引用文献数

- 8 41

Development in sheet steels has progressed with a strong relation with automotive industry in Japan. To meet with the requirements from automotive industry, various types of sheet steels including high and ultra-high strength steel sheets have been developed. Progresses in three types of steel series will be discussed by checking the historical facts and technologies and their contributions. Introductions of interstitial free (IF) steel and continuous annealing system are the important events in mild steel developments for panels. Extensive work on finding the optimum mixtures of hard and soft phases to improve elongation of steels contributed to improve the crashworthiness of autobodies. Continuous annealing system also played an important role in producing these advanced high strength steels. Precipitation is used in characteristic ways which is to scavenge solute carbon and nitrogen and to prevent coarse cementite particle precipitation. It is also worth to point out that the strong collaborative activities particularly characteristic in Japan between steel manufacturers and auto companies have affected on the progress in advanced sheet steels.

3 0 0 0 OA ディープラーニングによる組織識別率の検証

- 著者

- 足立 吉隆 田口 茂樹 弘川 奨悟

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.12, pp.722-729, 2016 (Released:2016-11-30)

- 参考文献数

- 9

- 被引用文献数

- 21

Deep learning by convolution neural network (CNN) was applied to recognize a microstructure of steels. Three typical CNN-models such as LeNet5, AlexNet, and GoogLeNet were examined their accuracy of recognition. In addition to a model, an effect of learning rate, dropout ratio, and mean image subtraction on recognition accuracy were also investigated. Through this study, the potency of deep learning for microstructural classification is demonstrated.

3 0 0 0 OA DP鋼の応力−ひずみ曲線を支配する組織因子のスパース学習

- 著者

- 弘川 奨悟 田口 茂樹 松下 康弘 足立 吉隆

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2017-003, (Released:2017-04-26)

- 参考文献数

- 12

- 被引用文献数

- 1

Screening important microstructure factors dominantly controlling a stress-strain curve of a dual phase steel was studied by three kinds of sparse modelling approach; Sensitive analysis, data transformation & variable selection, and Bayesian inference. In addition, an effect of data noise on descriptor screening in sparse modelling was also investigated.

3 0 0 0 OA 最近の高張力鋼について(II)

- 著者

- 山木 正義

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.45, no.5, pp.528-542, 1959-05-01 (Released:2009-05-26)

- 参考文献数

- 91

- 被引用文献数

- 1

3 0 0 0 OA サイクル熱処理したSUJ2鋼における微細組織と機械的性質

- 著者

- 酒井 久裕 落合 鍾一 上野 學

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.4, pp.657-664, 1989-04-01 (Released:2009-06-19)

- 参考文献数

- 22

- 被引用文献数

- 2

The purpose of this work is to present results on the mechanical properties of SUJ 2 bearing steel improved by a cyclic heat treatment. The structure of thermally cycled steel consists of fine-grained ferrite particles of the size under about 2 μm containing fine cementite particles of the size about 0.2μm. Thermally cycled steel was found to be superplastic at 710°C, just below A1 temperature, at an initial strain rate of 1.67 × 10 -4s -1, i.e. elongation to failure was about 500% and the strain rate sensitivity, m value, was about 0.4. The activation energy of about 180 kJ/mol, which is nearly equal to that of grain boundary diffusion of Fe atoms in α-iron, was obtained for this plastic deformation. Furthermore the rolling contact fatigue life test was performed at room temperature under constant load. The fatigue life of SUJ 2 steel thermally cycled was found to be prolonged (about 2.5 times) as compared with that of conventional one.

3 0 0 0 OA 低温用鋼の引張変形特性に及ぼすニッケル量の影響

- 著者

- 古谷 仁志 田川 哲哉 石川 孝司

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.5, pp.678-687, 2014 (Released:2014-04-30)

- 参考文献数

- 23

- 被引用文献数

- 2

Tensile behaviors of cryogenic steels, which contain 0 to 12wt% nickel, were examined to obtain the fundamental knowledge related to the role of retained austenite in the improvement of fracture toughness. Although retained austenite of 8% and 12% nickel steel, which were manufactured by the special heat treatment composed of quenching, intermediate heat treatment, and tempering, was stable under the deep cooling at –196 ºC, it transformed to martensite by straining around 10% at –196 ºC. The strain hardening behavior was divided into two categories. One is that the maximum strain hardening appears just after yielding, then the strain hardening gradually decreases with increasing strain. It was related to 0% to 2% nickel steels, which include less retained austenite. Another is that the strain hardening increases just after yielding with the increase of strain, then it gradually decreases. In this case, higher strain hardening was derived. It was related to 5% to 12% nickel steels which included a certain amount of retained austenite. The increase of strain hardening under low temperature was attributed to the solute nickel and the formation of martensite, which act as a hard second phase, by the work induced martensitic transformation.

3 0 0 0 OA 粒子モデル予測制御による鋼板温度のばらつき制御

- 著者

- 大角 洸平 大塚 敏之 平田 光男 塩谷 政典

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.99, no.4, pp.275-282, 2013 (Released:2013-03-26)

- 参考文献数

- 16

- 被引用文献数

- 1

In this paper, a control problem of temperature dispersion in steel cooling is formulated as model predictive control (MPC) of a probability density function (PDF). The input of MPC is optimized for dynamics of the PDF approximated by the Monte Carlo method, which is called particle MPC (PMPC). Simulation results of PMPC are presented to show the potential effectiveness of dispersion control.

3 0 0 0 OA 計算材料科学の進展と展望

- 著者

- 小野寺 秀博 阿部 太一 下野 昌人 小山 敏幸

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.10, pp.1207-1219, 2014 (Released:2014-09-30)

- 参考文献数

- 116

- 被引用文献数

- 2 3

Computational materials science is an exciting field which holds much future potential. In this article, at first, the dramatic advances of the computational methodologies are briefly summarized at scales from the atomistic to macroscopic levels. Then, each coauthor introduces the three research fields in detail, (1) CALPHAD modeling supported by key experiments and first-principles calculation, (2) Studies on the phase transformation in alloys based on the MD simulations, and (3) Predictions of the microstructure evolution and the mechanical properties based on the phase-field method, where remarkable progresses have been attained.

3 0 0 0 宇宙線ミュオン測定による高炉の炉内検知

- 著者

- 篠竹 昭彦 松崎 眞六 国友 和也 内藤 誠章 橋本 操 圃中 朝夫 長根 利弘 永嶺 謙忠 田中 宏幸

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.95, no.10, pp.665-671, 2009

- 被引用文献数

- 1 7

The visualization of the inner state of a blast furnace was investigated by exploiting the feature of cosmic-ray muon that attenuates according to the density and the thickness of the object through which it penetrates. The distribution of the cosmic-ray muon accumulated in an object in a blast furnace during a certain period has been determined by a probing system provided with two sets of a pair of panels with plastic scintillation counters segmented in parallel along each direction of both sides. First, measurement was performed in the furnace hearth structure that had been taken out after the shutdown of Oita No. 2 Blast Furnace repaired in 2004. Next, another measurement was performed in the same manner in the renewed furnace hearth of Oita No. 2 Blast Furnace which had just started working after its repairs. The density of the material at the iron-rich portion inside the hearth was estimated from the accumulation ratio obtained from the relation between the intensity of the muon channel passing through the iron-rich part in the hearth and that passing through its opposite channel symmetric to the coordinate origin. Then, the level of the furnace bottom brick, meaning its eroded thickness, was estimated from those accumulation ratios in relation to each channel crossing both the iron-rich part and the furnace bottom brick. The possibility of the density distribution of the material inside a blast furnace and the remaining thickness of bricks being estimated by this measurement method was identified.

2 0 0 0 OA 新技術開発部会直接還元法分科会報告日本における鉄鉱石直接還元技術の推移

- 著者

- 遠藤 勝治郎 松下 幸雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.48, no.6, pp.796-802, 1962-05-01 (Released:2010-02-22)

- 参考文献数

- 1

- 被引用文献数

- 1

2 0 0 0 OA 加速器質量分析(AMS)による和釘の14C年代と製造年代

- 著者

- 永田 和宏 古主 泰子 松原 章浩 國分(齋藤) 陽子 中村 俊夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.4, pp.488-491, 2019 (Released:2019-03-31)

- 参考文献数

- 16

- 被引用文献数

- 1 1

The Japanese nails had been produced by the traditional ironmaking way of Tatara until the Edo period since the late of 6 Century. The Tatara is characterized as the ironmaking using very fine iron sand as the resources and is distinguished from the pre-modern ironmaking way in Europe using lump iron ore. The quality of the Japanese nails is affected from steel produced by Tatara in each age. The 14C ages of 3 Japanese nails were measured with accelerator mass spectrometry and calibrated to calendar years. Each 14C age provided plural calendar year periods with definite probabilities, and one of the periods determined in comparison with the history of temples and their repair records. The production ages of nails used in the Daibutuden of the Todaiji temple, the living quarters of the Manshuin temple and the Zaoudo of the Yoshino-Kinpusenji temple are before 1692, the 12 Century and before 1592, respectively, when they were repaired or reconstructed.

2 0 0 0 OA ステンレス鋼の常温におけるクリープ変形挙動

- 著者

- 天藤 雅之 竹下 哲郎 中澤 崇徳 木村 英隆 安保 秀雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.79, no.1, pp.98-104, 1993-01-01 (Released:2009-06-30)

- 参考文献数

- 14

- 被引用文献数

- 14 21

Room temperature creep behavior has been investigated for typical stainless steels (SUS304, SUS430, SUS410L). The mechanism of creep is discussed in comparison with creep data on a carbon steel (SM400).The results are summerized as follows:1) Stainless steels showed creep deformation at a stress around 0.2% proof stress. Though creep rate decreased monotonously with increase in time, deformation did not ceased even at a time 1000 h. The creep curve of SUS304 steel followed a logarithmic creep law.2) No creep was observed in steel SM400 below a critical strain rate at around 10-8S-1.3) The facts that interstitial free steels showed room temperature creep, and that SUS304 steel showed no creep at 300°C suggest that the suppression of creep can be attributed to the dynamic strain aging due to the interaction between dislocation and interstitial carbon and nitrogen atoms.

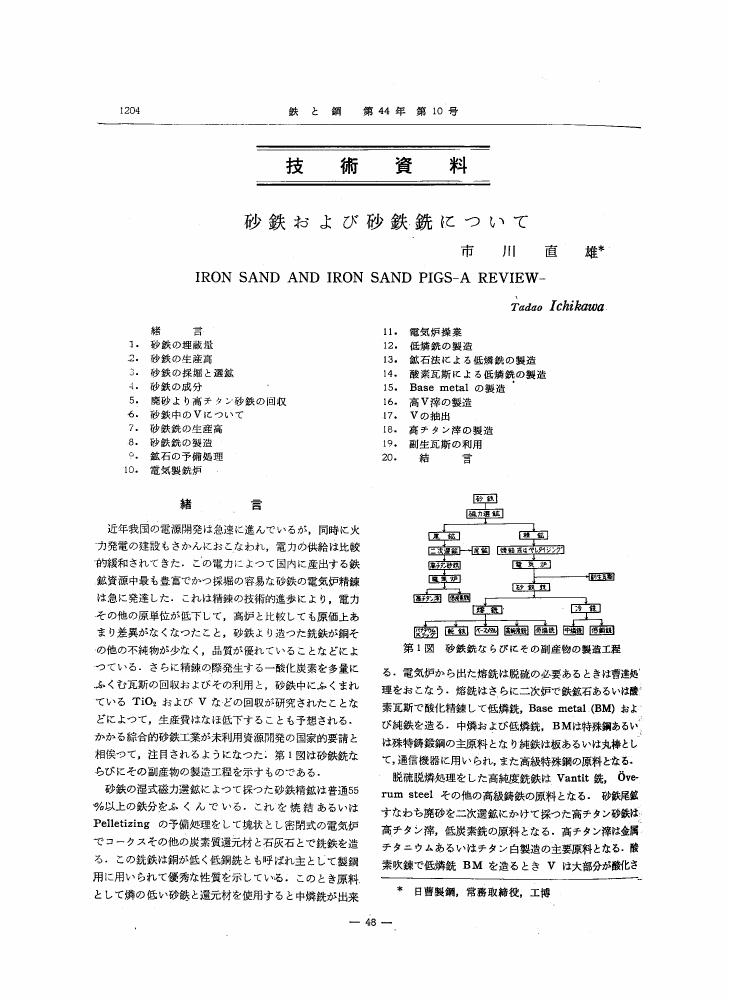

2 0 0 0 OA 砂鉄および砂鉄銑について

- 著者

- 市川 直雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.44, no.10, pp.1204-1216, 1958-10-01 (Released:2009-05-26)

2 0 0 0 OA 製鋼スラグを利用した藻場再生技術における腐植物質の鉄溶出への影響

- 著者

- 山本 光夫 福嶋 正巳 劉 丹

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.97, no.3, pp.159-164, 2011-03-01 (Released:2011-03-01)

- 参考文献数

- 16

- 被引用文献数

- 16 17

Barren grounds in coastal area are serious problems in Japan and throughout the world. Although several factors have been proposed to account for barren grounds, we have especially focused on lack of dissolved iron for restoring seaweed beds. It has been developed a method that the mixture of steelmaking slag and humus materials, such as composts, were supplied in seawater. A concentration of dissolved iron can be increased by using the method, since complexes, iron-humates, are produced from iron in steelmaking slag and humic substances in compost. In this study, we evaluated the effect of humic substances in this method for increasing dissolved iron concentration. A laboratorial iron elution test by using actual seawaters was attempted. Three kinds of samples for iron elution, only steelmaking slag, only humus materials, and a mixture of steelmaking slag and humus materials, were prepared. The change of iron concentration in each small tank had been monitored. We found that iron elution rate in the case of the mixture of steelmaking slag and compost was faster than that in the case of only steelmaking slag. Furthermore, it was expected that the characteristic of the structure of humic substances were related to increase iron elution from steelmaking slag. The mixture of steelmaking slag and humus materials was more effective not only for increasing iron concentration in seawater and but also for extending the life time of Fe elution.

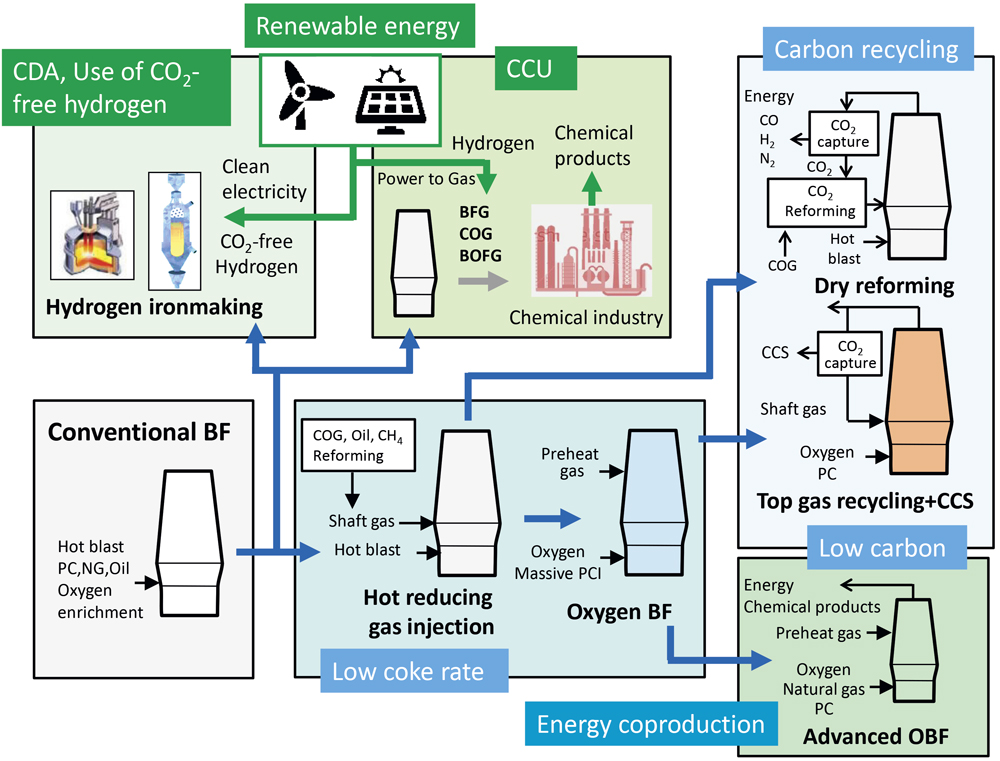

2 0 0 0 OA 鉄鋼における二酸化炭素削減長期目標達成に向けた技術展望

- 著者

- 有山 達郎

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.6, pp.567-586, 2019 (Released:2019-05-31)

- 参考文献数

- 81

- 被引用文献数

- 4 16

Global warming has been regarded as a crucial issue in every industry. Since long term global goal was set on the basis of Paris Agreement, a considerable evolution toward CO2 mitigation in 2050 is desired even in steel industry. Until now, many various technology developments were carried out in the ironmaking area; however, the innovative progress beyond the past progressive developments is required to attain the long-term goal in 2050. This review focuses on the current technology development on CO2 mitigation to date and the design of an ambitious ironmaking process for the future. In particular, the directions for low carbon and decarbonization are discussed from the viewpoints of technological aspects and the comprehensive consistency with sustainability in steel industry. Moreover, the perspectives on CCU (CO2 Capture and Utilization) and hydrogen ironmaking process based on the renewable energy aiming for carbon direct avoidance are described.

2 0 0 0 OA 橋梁における高力ボルトの遅れ破壊

- 著者

- 松山 晋作

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.8, pp.903-912, 1983-06-01 (Released:2009-06-30)

- 参考文献数

- 16

- 被引用文献数

- 6 8

実橋における高力ボルトの遅れ破壊に関する事例解析結果をまとめると次のようになる.1) 橋梁の桁構造別にみると箱桁における損傷例が多かつた.これは桁内部に水が溜まるために日照時には高温高湿条件となり腐食反応が生じやすいためである.したがつて,箱桁には水抜き孔を設けて桁内部が乾燥状態を保つようにすることが破損防止上必要である.2) 橋梁によつて破損が上フランジ,ウェブ,下フランジなどのある箇所に集中する傾向が認められた.この原因は明らかではないが,ボルトの遊びねじ長さ,水滴の溜まりやすさ,温度上昇度など,ボルトの製造ロット別に生ずる材質的差異以外の要因が考えられる.3) ボルトの破断部位は不完全ねじ部が一般的には多いが,橋梁によつては首下破断が多発する場合もあつた.規格上は首下はねじ部より強い筈であるから,首下破断を生ずる理由には,第一に頭が下向きの場合首下に水滴が溜まりやすいこと,第二に首下の丸み部に座金の角があたり荷重が集中したことが考えられる.とくに後者の場合には座金が遅れ破壊してボルト孔内部への水の浸入を容易にすることもある10)ので,座金の内側隅は十分面とりする必要がある.4) F 13T (No.4)を適用した唯一の橋梁で約15年間にわたりボルトの破損傾向を追跡調査した.その結果ボルト破損の確率分布は二母数ワイブル分布に従うことが認められた.継手のすべりに対する安全率を考えると,破損の補修をしなかつた場合にはこの橋梁は約40年で変状を生ずると推定された.5) F 11Tを使用した橋梁で最初の破損を生ずるまでの寿命分布も二母数ワイブル分布で表され,故障率が時間と共に低下する傾向を示した。現在F 11Tの使用は中止されているから,すでにF 11Tを使用している既設の橋梁での遅れ破壊事例は今後減少傾向にあると推定される.6) 高力ボルトを適用した初期の橋梁や遅れ破壊を発生した橋梁についてボルトを採取して軸部の鉄さびの分析を行つた.直接雨に曝された箇所や箱桁ではボルトが湿つた状態にあるものが多かつたが,鉄さびの組成からも水の存在が認められた.遅れ破壊は水の存在下で腐食反応の結果生ずる水素により誘起されるもので,乾燥状態で使用されていれば遅れ破壊は生じない.7) 破面の破壊起点部には旧オーステナイト粒界割れがみられた.材料によつては破壊途中で圧延方向にミクロ偏析帯に沿つて粒界割れを生ずる縦割れが認められた.8) 遅れ破壊を生じたボルトの最小硬さはHRC 37.5であつた.従来の実験から得られた遅れ破壊を生ずる限界硬さはHRC 41であるから,HRC<41で破損したボルトは材質的鋭敏化原因があつたと考えられる.その原因として,浸炭による表面硬化, Pの粒界偏析, Bの粒界における存在などが考えられた.これらの原因の検討から,熱処理炉の雰囲気は脱炭傾向にすること,可能な限り低燐の高純度鋼を用いること, B添加は必要最少量にすることなどが高力ボルトの信頼度を高めるために必要であると結論される.しかし市販鋼では高純化には限度があるから粒界炭化物が十分凝集するまで焼もどし温度を高めることが必要である.9) 一般に炭素量が多いと焼もどし軟化曲線の勾配が急になり,焼もどし温度変化の硬さへの影響が大きくなるから,炭素量の多い鋼種で高強度化するのは望ましいことではない.またバッチ型焼もどし炉のように装入方法によつては温度むらを生ずる場合には,一部に焼もどしが不十分で硬さの高い製品が混入する可能性があるので注意が必要である.

2 0 0 0 OA ボルトの遅れ破壊

- 著者

- 中里 福和

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.88, no.10, pp.606-611, 2002 (Released:2009-06-19)

- 参考文献数

- 54

- 被引用文献数

- 12 14

This review article on delayed fracture of bolts covers the following topics: general features of delayed fracture, case histories of in-service failures of high-strength bolts, existing demands for higher-strength bolts and their background, increasing needs for standardization of delayed fracture susceptibility evaluation method, and approaches so-far taken to prevent delayed fracture. The author emphasizes that, thanks to the recent intensive R&D activities, overcoming delayed fracture is now very close to the reality.