1 0 0 0 OA 抄録

1 0 0 0 OA 高温におけるクリープおよび疲労

- 著者

- 大谷 隆一

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.14, pp.2106-2118, 1980-12-01 (Released:2009-06-19)

- 参考文献数

- 57

- 被引用文献数

- 3 5

1 0 0 0 OA 複合サイクル腐食試験における有機複合被覆鋼板の腐食挙動

- 著者

- 筋田 成子 望月 一雄 森戸 延行

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.84, no.11, pp.777-784, 1998-11-01 (Released:2009-06-19)

- 参考文献数

- 26

- 被引用文献数

- 3 3

Organic composite coated steel sheets show their excellent corrosion resistance during cyclic corrosion tests (CCT). To clarify corrosion behavior of these sheets, changes in corrosion products and elements of plating, chromate and organic resin layers during CCT were examined. Formation of crystalline ZnCl2·4Zn(OH)2 and superficial amorphous zinc carbonate were detected by X-ray diffraction, fourier transform infrared spectroscopy and Raman spectroscopy. And besides it was found by electron probe micro analysis, chemical analysis and fourier transform infrared spectroscopy that the corrosion products formed on organic resin layer contained silicon as zinc silicate from silica in organic resin layer.Consequently, weight of zinc in plating layer and silica in organic resin layer decreased, while that of nickel in plating layer, chromium in chromate layer and carbon in organic resin layer remained constant, and the corrosion products formed on organic resin layer contained zinc and silicon dissolved from each layer during CCT.

- 著者

- 川上 正博 永田 和宏 山村 稔 坂田 直起 宮下 芳雄 後藤 和弘

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.63, no.13, pp.2162-2171, 1977

- 被引用文献数

- 16

Local temperature and voltage in the molten flux and metal pool beneath the electrode of ESR porcesses were measured directly by a bare hot junction of W-WRe thermocouple.<BR>The temperature in the flux during remelting was almost uniform at 1750±30°C. No temperature gradient was found at the metal pool-flux interface. The temperature in the metal pool decreased smoothly downward in the pool with a platea at 1500°C which was the liquidus temperature of the steel used.<BR>The iso-voltage line was densely distributed at the electrode-flux interface and broadened toward the metal pool-flux interface. Most of the “Joule heat” in the flux was generated very close to the electrode. However, Faradaic heat generation at the electrode-flux interface was hardly found.<BR>It is suggested from the experimental results that refining processes, not only slag-metal reaction but also inclusion removal take place mainly at the metal pool-flux interface. Because the temperature in the flux was uniform even with the localized heat generation, a violent convection should exist in the flux.<BR>One of the driving forces for the convertion, the pinch effect of the current, was calculated. The selection of the proper voltage and current in order to have a good shape of the metal pool was suggested on an I-V diagram.

1 0 0 0 OA 50年間大気暴露試験における溶融Alめっき鋼板の腐食挙動

- 著者

- 真木 純

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.7, pp.759-766, 2019 (Released:2019-06-30)

- 参考文献数

- 17

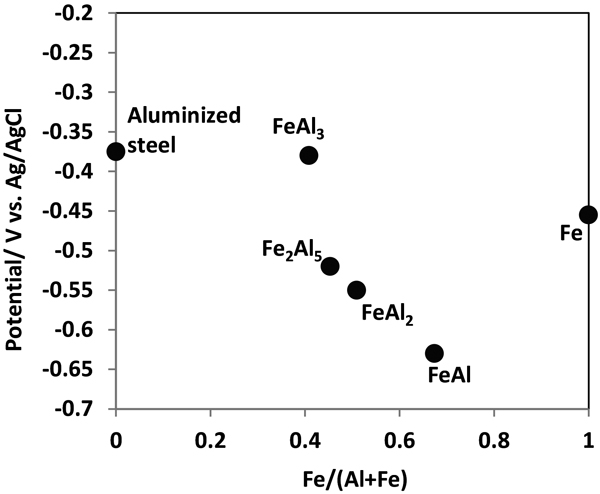

Aluminized steel sheets are very resistant to corrosion in the outdoor exposure environment. We evaluated the corrosion behavior of aluminized steel sheets with a Type1 coating containing around 10%Si but also a Type2 coating not containing Si in a 50-year outdoor exposure test. Both specimens had strong perforation resistance, but those with Type2 coating had superior perforation resistance. The Type2 aluminized steel sheets had two sublayers composed of Fe2Al5 and FeAl2 as the intermediate layer between the aluminized layer and the steel substrate. The FeAl2 phase has less noble potential than steel substrate and the Fe2Al5 phase in an artificial rain water environment. As a result, this layer provided sacrificial corrosion protection for the steel substrate. That was why the specimens with the Type2 coating had better perforation resistance than those with Type1 coating.

1 0 0 0 OA 円柱鋼材の冷却過程における熱応力の計算

- 著者

- 坂井 一男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.12, pp.1591-1598, 1974-10-01 (Released:2010-10-12)

- 参考文献数

- 12

- 被引用文献数

- 3 4

The paper presented a calculation of thrmal stress in a cylindrical steel induced during cooling by introduction of strain-history into Hara's calculation method.Calculation was based on elastic-plastic theory and total strain was calculated by non-linear integral equation through a successive integration. Plastic strain was calculated by total strain theory and stress-strain diagram.A calculation was made for a cylindrical steel bar with 1500mm in diameter quenched in mist from 850°C, and the results are as follows.(1) Tensile stresses (δt, δz, ) at surface of bar are the largest, when temperature difference between surface and core was the largest.(2) Stresses (δt, δz) at starting point of transformation always show the maximum tensile values.(3) Reverse of stresses (δr, δt, δz) takes place after completion of transformation of core.(4) At final stage of cooling, core has tensile stresses (δr, δt, δz) and surface layer has compressive stresses (δt, δz) of characteristic pattern.

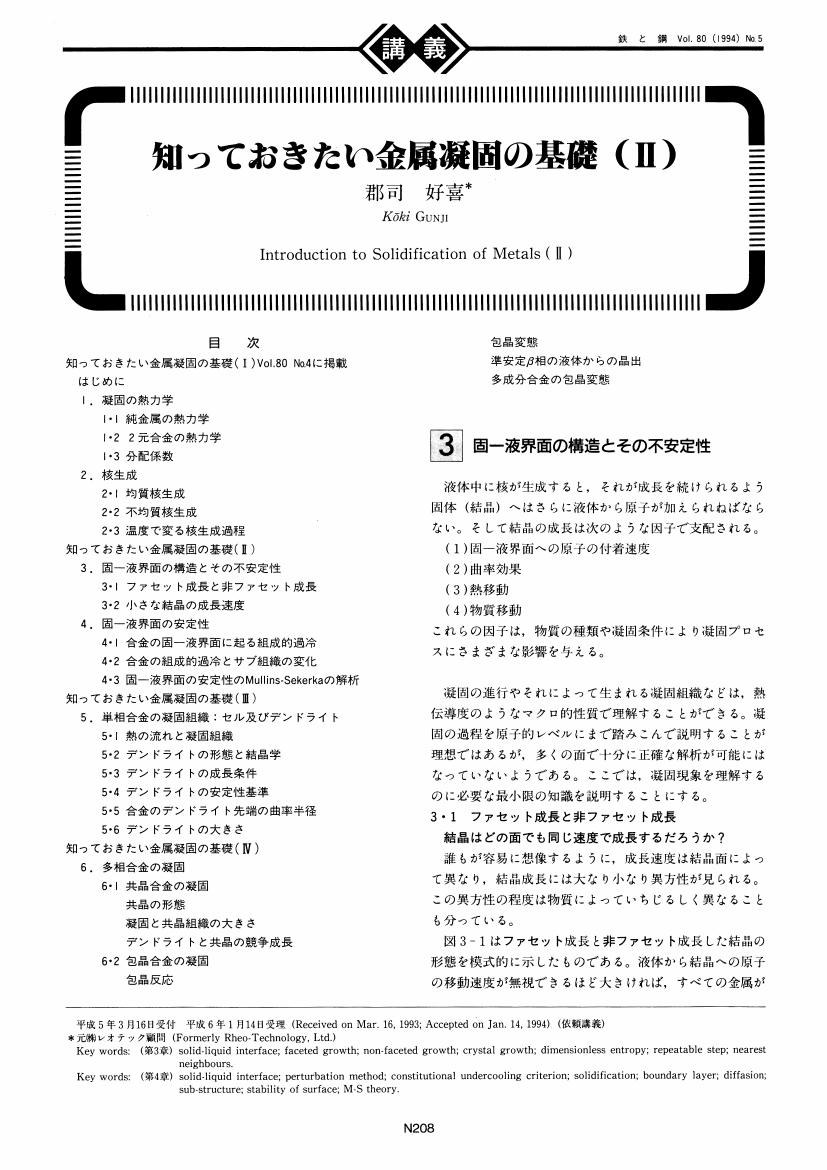

1 0 0 0 OA 知っておきたい金属凝固の基礎(II)

- 著者

- 郡司 好喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.5, pp.N208-N221, 1994-05-01 (Released:2009-06-19)

- 参考文献数

- 27

- 被引用文献数

- 2

1 0 0 0 OA 燃焼の基礎技術(II)

- 著者

- 水谷 幸夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.8, pp.774-784, 1984-06-01 (Released:2009-06-30)

- 参考文献数

- 11

- 被引用文献数

- 1 1

1 0 0 0 OA 日本鉄鋼業における計算機制御の進歩

- 著者

- 野坂 康雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.59, no.5, pp.557-569, 1973-04-01 (Released:2010-10-12)

- 参考文献数

- 5

- 被引用文献数

- 1 1

1 0 0 0 高炉製銑法,直接製鉄-電気炉法,溶融還元法のエクセルギー解析

- 著者

- 秋山 友宏 八木 順一郎

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.74, no.12, pp.2270-2277, 1988

- 被引用文献数

- 3 14

Exergy analysis was conducted on three ironmaking systems which were conventional ironmaking, direct reduction-electric furnace and smelting reduction systems. The exergy analysis is better than an enthalpy balance or a heat balance because exergy can express the quality of energy and evaluate different forms of energy like chemical, thermal, pressure and mixing energy by a unified measure.<BR>According to the calculated results for the specified conditions, the smelting reduction system was the lowest in net exergy loss, however, the highest in overall output exergy. The development of the efficient heat recovery process is therefore required for this system. The direct reduction-electric furnace system was the highest in net exergy loss. However, nonfired pellets were found to be effective to reduce net exergy loss. In the conventional ironmaking system, net exergy loss of its constituent processes significantly depended on the injection rate of pulverized coal and on the charging amount of nonfired pellets.

1 0 0 0 OA 鉄鉱石の全鉄を含む蛍光X線分析 −ISO/WD 9516-2規格案と検証結果−

- 著者

- 片岡 由行 森川 敦史 古主 泰子 牧田 正弘 吉永 亨二 木戸 直範

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.5, pp.560-565, 2019 (Released:2019-04-30)

- 参考文献数

- 4

An accurate quantitative analysis method including total iron had been proposed for the iron ore analysis by wavelength dispersive X-ray fluorescence spectrometry using fusion method and was accepted at ISO TC 102 meeting in 2010. The project has been proceeded in ISO TC 102/SC 2/WG54 as ISO/WD 9516-2 project. Number of covered elements is 19, and 14 elements among them including total iron are for referee analysis. The calibration discs are prepared only from reagents and the calibration equation includes coexisting component correction, overlap correction, flux/sample and oxidizer/sample mixing ratio corrections. The coexisting component correction method is based on the absorption/enhancement correction coefficients obtained by a FP (fundamental parameter) method so that LOI (loss on ignition) and GOI (gain on ignition) during fusion do not affect to analyzed results. In the verification experiments with 20 certified reference materials, the accuracy obtained by root mean square of the difference between certified values and analyzed values using proposed method was 0.14 mass%, which indicated analytical accuracy could be greatly improved compared with the existing method. For the other components, the values of accuracy obtained were almost same as the existing method. We are conducting final round-robin test in foreign laboratories and have a plan to set the method as an ISO standard.

1 0 0 0 OA 自動車車体用薄鋼板とその成形技術の動向

- 著者

- 吉田 清太

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.63, no.9, pp.1588-1596, 1977-08-01 (Released:2010-03-15)

- 被引用文献数

- 2

1 0 0 0 日本鉄鋼協会第95回講演大会講演概要:加工

- 著者

- 宮島 明 山田 健夫 安藤 静吾 国岡 計夫 杉山 峻一 神尾 寛 島田 勝彦 角崎 周市 富川 隆信 山田 正義 小峰 勇 米谷 捻 角崎 周市 山田 正義 田辺 英也 森田 博之 入谷 正夫 宇野 義雄 手塚 栄 吉田 謙吾 小橋 正満 山田 信男 宮崎 四郎 西出 輝幸 浜田 一明 小西 敏弘 藤原 洋一 上田 正美 東 良学 片山 知行 高橋 昭夫 吉村 清信 土屋 安夫 天野 虔一 佐藤 俊彦 桑島 英明 浜島 吉男 高橋 亮一 川野 晴雄 横井 玉雄 成合 靖正 高力 満 鎌田 晃郎 高野 道典 山口 久 寺本 和啓 中山 武典

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.64, no.4, pp.S245-S256, 1978

1 0 0 0 OA フェライト/セメンタイト積層体の延性に関する結晶塑性解析:界面の転位吸収能力の影響

- 著者

- 安田 洋平 下川 智嗣 大橋 鉄也 新山 友暁

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2018-082, (Released:2018-11-01)

- 参考文献数

- 27

- 被引用文献数

- 2

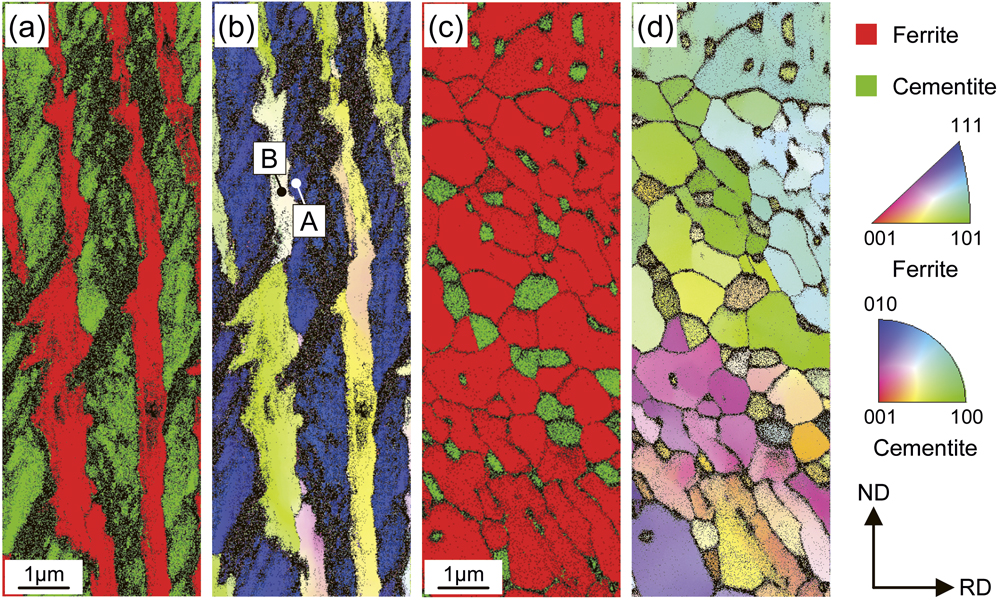

Strain hardening behavior of ferrite layers in the microstructure of drawn pearlite wire is studied theoretically and numerically. It is shown that stress field associated to dislocations could diminish quickly if the dislocations enter the phase or grain boundaries and decompose into smaller segments to distribute along the boundary. Some atomistic simulations of single-phase media validate this phenomenon; dislocations show to pass, decompose or accumulate on tilt-type grain boundaries depending on their atomistic configuration. Mechanical responses of nine-layered pearlite models subjected to tensile load are analyzed by a strain gradient crystal plasticity finite element code, where possible passage or absorption of dislocations is expressed in the model of dislocation mean free path. The critical resolved shear stress for slip systems consists of the lattice friction, the Taylor and Orowan terms and the strain hardening is given by the Taylor one. The density evolution of accumulated dislocations is evaluated by the model of Kocks and Mecking where the dislocation mean free path plays a major role. Results show that the smaller the dislocation absorption ability of the phase boundary and thinner the layer thickness, larger the strain hardening becomes. Slip localization in cementite layers is shown to be suppressed when the strain hardening of ferrite layers is higher, and this trend is consistent with results obtained in previous studies by molecular dynamics simulation and classical elasto-plasticity analyses. Scale sensitive phenomena taking place at phase boundaries in layered structure are briefly discussed in views of atomistic process and continuum mechanics.

1 0 0 0 OA パーライトにおける内部応力の動的緩和と結晶方位関係の選択

- 著者

- 雨宮 雄太郎 中田 伸生 諸岡 聡 小坂 誠 加藤 雅治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.2, pp.314-323, 2019 (Released:2019-01-31)

- 参考文献数

- 28

- 被引用文献数

- 5

For deeper understanding of a dynamic accommodation mechanism of internal stress in pearlite originated from the lattice misfit between ferrite and cementite phases, the lattice parameter ratios of cementite, bθ/aθ and cθ/aθ, were locally analyzed in detail by using the electron backscatter diffraction (EBSD) technique. The EBSD analysis has revealed that lattice parameter ratios of cementite lamellae obviously differ from those of spheroidized cementite particles, which demonstrates that pearlite has a certain amount of internal stress as long as it maintains lamellar structure. The internal stress in pearlite gradually decreased during isothermal holding at 923 K after pearlitic transformation due to interfacial atomic diffusion of iron atoms. However, comparing with theoretical values under Pitsch-Petch orientation relationship, it was understood that large amount of internal stress had been already accommodated upon pearlitic transformation by introduction of misfit dislocations and structural ledges on ferrite/cementite lamellar interfaces. That is, the internal stress of pearlite is dynamically reduced by two different processes; built-in accommodation upon pearlitic transformation and additional time-dependent relaxation after pearlitic transformation. On the other hand, EBSD analysis and neutron diffraction technique gave remarkably different lattice parameters of cementite. From this result, it is concluded that various crystallographic orientation relationships between ferrite and cementite coexist in pearlite. Furthermore, elastic strain energy analysis suggests that the invariant-line criterion on ferrite/cementite interface plays an important role for the selection of orientation relationships in pearlite.

1 0 0 0 OA わが国のばね鋼の進歩発展について

- 著者

- 阿部 芳平

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.76, no.12, pp.2059-2064, 1990-12-01 (Released:2009-06-30)

The report discusses the recent development of spring steel in Japan during last 40 years. There has been a great increase in this steel production with the increase of production of automobiles. The technical trends of spring steel and springs are discussed in connection with hardenability, fatigue, high-stressed design and productivity. Especially, ways of improvement of performance of springs for suspention of automobiles were studied in respect to chemical composition, heat-treatment and manufacturing process.

1 0 0 0 OA 流れにおける渦の生成

- 著者

- 亀本 喬司

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.76, no.3, pp.320-328, 1990-03-01 (Released:2009-06-30)

- 参考文献数

- 26

- 被引用文献数

- 2 2

流れの中に渦が発生するメカニズムは,流れの初期条件や境界条件によってかなり相違があるが,本質的には渦度がどのように供給され,それらがどのように流れるかによっていることは本文に説明したとおりである. 自然界における空気や水の流れを見ても,渦を伴わないものはほとんど無いと言っても過言ではない.技術の粋を集めて作られた航空機でもひとたび設計条件からはずれると,Fig.7に示したような流れの剥離により失速状態に陥ることもあり,渦とはこれほど発生しやすいものと考えたほうが良さそうである.流れにおける渦の生成を,さまざまな条件下で意のままにコントロールできたとすれば,それは正に人間にとって夢の実現に値するものである.鳥や魚のように,渦無しの流れと渦放出を巧みに使い分けることもできるし,台風やたつ巻の,発生や進路を自由に制御することもできるようになる.流れにおける渦の生成に関する研究を行っていると,流体が時として生き物のように感じられ,「流れは, 自身の姿を自由に変え,常に流れやすいように流れている」ように見えてくる.要は,「流れの気持ち」が理解できるようになることであろうか.溶けた鉄の流れがどのような性質を持つ生き物なのかについては,ご専門の技術者や研究者の方々が解き明かしてくださるものと楽しみにしている.この分野の方々にとって,本文が多少なりともご参考になれば幸いである.

1 0 0 0 OA B添加鋼のγ/α変態および析出挙動に及ぼすMoの影響

- 著者

- 藤城 泰志 原 卓也 重里 元一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.101, no.5, pp.300-307, 2015 (Released:2015-04-30)

- 参考文献数

- 25

- 被引用文献数

- 2 12

Effect of the combined addition of molybdenum (Mo) and boron (B) on austenite (γ) to ferrite (α) transformation and precipitation behavior were investigated using low-alloy steels. B-added steel and Mo-B combined steel were held at 923 K (γ region) in order to precipitate boride. B content as precipitates increased and γ to α transformation was promoted with holding time at 923 K. In B-added steel, both M23(C,B)6 and M2B were observed. The transition from M23(C,B)6 to M2B caused by the increase in holding time at 923 K. By contrast, in Mo-B combined steel, no M2B was observed regardless of the holding time. Mo addition suppresses not only the M23(C,B)6 formation but also the M2B formation. M2B contains larger amounts of B than M23(C,B)6. B content as precipitates in Mo-B combined steel was much lower than that in B-added steel due to the suppression of M2B precipitates. The effect of Mo for B containing steel suppresses the precipitation of M23(C,B)6 and M2B and increases more segregated B in austenite grain boundary that contributes to γ to α transformation.

- 著者

- 植森 龍治 向井 俊夫 谷野 満

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.77, no.11, pp.2060-2067, 1991-11-01 (Released:2009-06-19)

- 参考文献数

- 20

- 被引用文献数

- 1 1

Partition of alloying elements between spinodally-decomposed phases in Fe-Cr-Co-Si alloys was examined by Atom-Probe Field-Ion Microscope (AP-FIM). The results showed that the ferromagnetic particle (α1) is rich in Fe and Co, and the weak-ferromagnetic matrix (α2) rich in Cr and Si. The enrichment of Si in the α2 phase was explained through thermodynamical considerations. Si is more strongly bonded to Cr than to Fe. The improvement of hard magnetic properties by Si additions was found and discussed in terms of the changes in saturation magnetization of the α1 and α2 phases. The increase in coercive force may be mainly attributed to the reduction of saturation magnetization of the α2 phase by the addition of Si.

1 0 0 0 OA 二相ステンレス鋼のσ相析出挙動

- 著者

- 前原 泰裕 小池 正夫 藤野 允克 邦武 立郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.3, pp.577-586, 1981-03-01 (Released:2010-01-18)

- 参考文献数

- 33

- 被引用文献数

- 11 27

Precipitation of σ phase in an Fe-25Cr-7Ni-3Mo alloy with a duplex structure of α and γ phases, has been studied systematically by means of optical microscopy, X-ray diffraction, hardness measurement, tensile test, SEM observation and dilatometric measurement. The results obtained in this study are as follows: (1) TTT diagram for the precipitation of σ phase was a C-type with a nose at about 820°C and 2030 min. (2) σ phase nucleated on the α/γ boundaries and grew into α grains, and thereafter the nucleation of σ and new γ phases began also in α grains. Volume fraction of α phase decreased and that of γ phase increased with increasing σ phase. Precipitation of σ phase occurred by the reaction, α→σ+γ. It was found that Cr, Mo and W were concentrated into α phase. (3) Increase of hardness with precipitation of α phase was not so large, on the contrary, impact value decreased drastically even at a few percent precipitation of α phase. α phase was also found to be harmful for hot ductility. (4) The precipitation range during cooling were about 700900°C and a phase precipitation could be avoided if cooling rate were larger than about 20°C/min after solution treatment. It was clarified from the above results that α embrittlement during production of duplex phase stainless steels could be avoided by selecting adequate manufacturing conditions.