1 0 0 0 OA ドイツクラウスタール大学の思い出

- 著者

- 野田 龍彦

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.65, no.12, pp.1814-1815, 1979-10-01 (Released:2010-02-22)

1 0 0 0 OA 極低温における金属, 合金の機械的性質

- 著者

- 福島 英二

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.61, no.10, pp.2501-2513, 1975-08-01 (Released:2010-10-12)

- 参考文献数

- 54

- 被引用文献数

- 1 1

1 0 0 0 OA 5%Mn鋼における残留オーステナイトの機械的特性に及ぼす影響

- 著者

- 棗田 浩和 北原 周 橋本 俊一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.9, pp.525-533, 2016 (Released:2016-08-31)

- 参考文献数

- 31

- 被引用文献数

- 9 14

Recently, 5% Mn steel has been focused on as one of the promising candidates for third generation AHSS by showing an excellent TS-El relationship. The excellent TS-El relationship is brought about by a large volume fraction of retained austenite through the enrichment of austenite stabilizing elements such as C and Mn in reverted austenite. The effect of the microstructure of mother hot band on the changes in microstructure and mechanical properties was compared with the intercritical annealing time in this study. The steel containing about 10% of retained austenite in a mother hot band exhibited a higher volume fraction of retained austenite and higher strength. On the other hand, the steel which did not contain retained austenite in a mother hot band exhibited excellent strength-elongation combination. The difference of work hardening behavior in these steels was analyzed and thought to be brought about by the difference of transformation behavior during deformation determined by the stability of retained austenite affected by Mn concentration.

1 0 0 0 OA 初歩的な人工知能によるDP鋼の高次元組織データ駆動型応力−ひずみ曲線の予測

- 著者

- 足立 吉隆 新川田 圭介 奥野 晃弘 弘川 奨悟 田口 茂樹 定松 直

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.1, pp.47-55, 2016 (Released:2015-12-31)

- 参考文献数

- 19

- 被引用文献数

- 6 6

Prediction of a stress-strain curve of ferrite-martensite DP steels was studied by a combined technique of Bayesian inference and artificial neural network. To screen a descriptor to be used for neural network analysis, material genomes such as volume fraction, micro-hardness, handle, and void of martensite phase, and micro-hardness of ferrite phase were examined by Bayesian inference. In a case of small data set, a machine learning method to predict mechanical properties reliably was proposed.

1 0 0 0 OA DP鋼の応力−ひずみ曲線を支配する組織因子のスパース学習

- 著者

- 弘川 奨悟 田口 茂樹 松下 康弘 足立 吉隆

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.103, no.8, pp.468-474, 2017 (Released:2017-07-31)

- 参考文献数

- 12

- 被引用文献数

- 1 1

Screening important microstructure factors dominantly controlling a stress-strain curve of a dual phase steel was studied by three kinds of sparse modelling approach; Sensitive analysis, data transformation & variable selection, and Bayesian inference. In addition, an effect of data noise on descriptor screening in sparse modelling was also investigated.

1 0 0 0 製鉄工業と輸送問題

- 著者

- 嘉村 平八

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.47, no.12, pp.1663-1664, 1961

1 0 0 0 OA 氷の破壊靱性

- 著者

- 浦辺 浪夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.7, pp.908-916, 1981-05-01 (Released:2009-06-19)

- 参考文献数

- 26

1 0 0 0 OA 予備還元処理および物理選鉱による高リン鉄鉱石からのリン除去

- 著者

- 久保 裕也 丸岡 伸洋 佐藤 嘉将

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.9, pp.871-876, 2019 (Released:2019-08-31)

- 参考文献数

- 12

- 被引用文献数

- 3

Fundamental experiments were conducted with the aim of crude separation of the phosphorus contained in high-P iron ore prior to the ironmaking process. By reducing high-P iron ore with lime and graphite at an appropriate blending ratio and temperature, a reduction product was obtained consisting of a P-concentrated phase, metallic Fe with low P, and an Fe oxide-containing phase. The reduction product was pulverized by electrical pulse disintegration, and a magnetic separation experiment was performed for each particle group. As a result, 57.5% of the P contained in the reduction product was removed by removing particles of 250 μm or less. Samples simulating the constituent phases of the reduction products were synthesized and subjected to magnetization measurement. It was assumed that the Fe oxide-containing phase was paramagnetic and the P-concentrated phase was diamagnetic. We calculated the magnetic and drag forces acting on the paramagnetic particles in wet magnetic separation. When the magnetic field gradient was low, the magnetic forces acting on the fine particles were low, and attraction was difficult due to the drag force of water.

1 0 0 0 OA 知っておきたい金属凝固の基礎(III)

- 著者

- 郡司 好喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.6, pp.N266-N280, 1994-06-01 (Released:2009-06-19)

- 参考文献数

- 53

- 被引用文献数

- 1 3

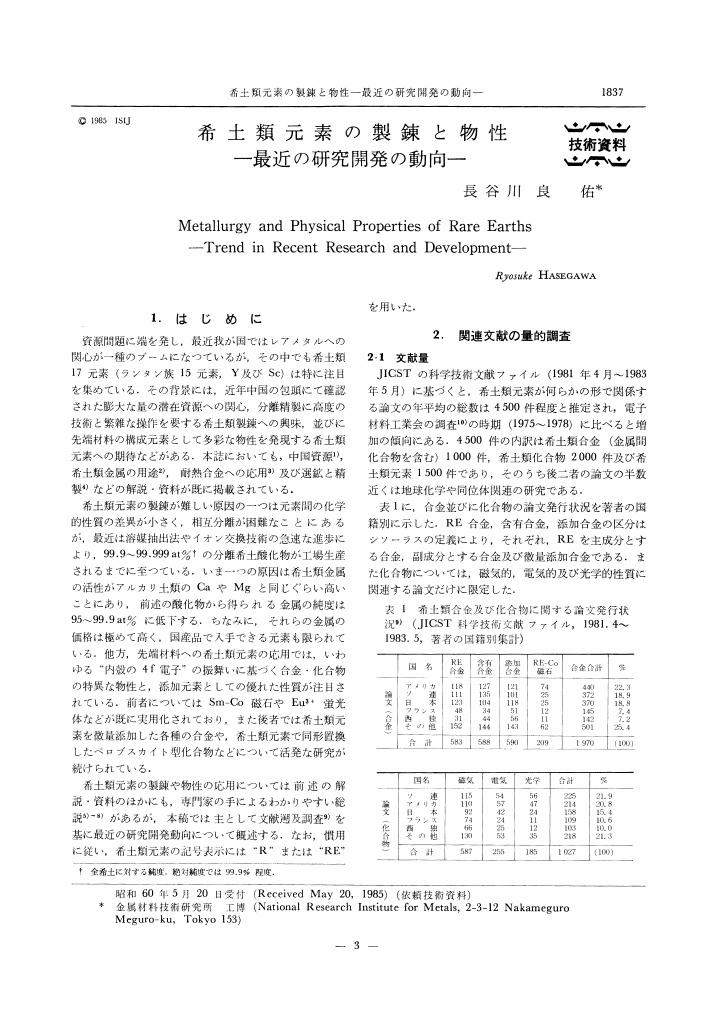

1 0 0 0 OA 希土類元素の製錬と物性

- 著者

- 長谷川 良佑

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.16, pp.1837-1845, 1985 (Released:2009-06-19)

- 参考文献数

- 34

1 0 0 0 OA 鉄仏の製作年代と古伝書「古今鍛冶備考」からみた銑押し法と〓押し法の成立期の検討

- 著者

- 鈴木 卓夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.97-102, 2005-01-01 (Released:2010-01-19)

- 参考文献数

- 15

- 被引用文献数

- 1 1

"Tatara" is a traditional box-type furnace in Japan and had produced iron from iron sand and charcol. In this Tatara there were two techniques which were called Zuku-Oshi and Kera-Oshi. Zuku means pig-iron and Kera means steel. The Tatara started in the latter half of six century and is continuing up to today. I am interested in when did the two techniques establish. So I tried to investigate the question with data of iron (pig-iron) image of Buddha making age and old document which is called "Kokon-Kajibiko". It is concluded that Zuku-Oshi has established regularly in Kamakura period (1192-1333). In Kera-Oshi case is the latter half of Muromachi period (1392-1573).

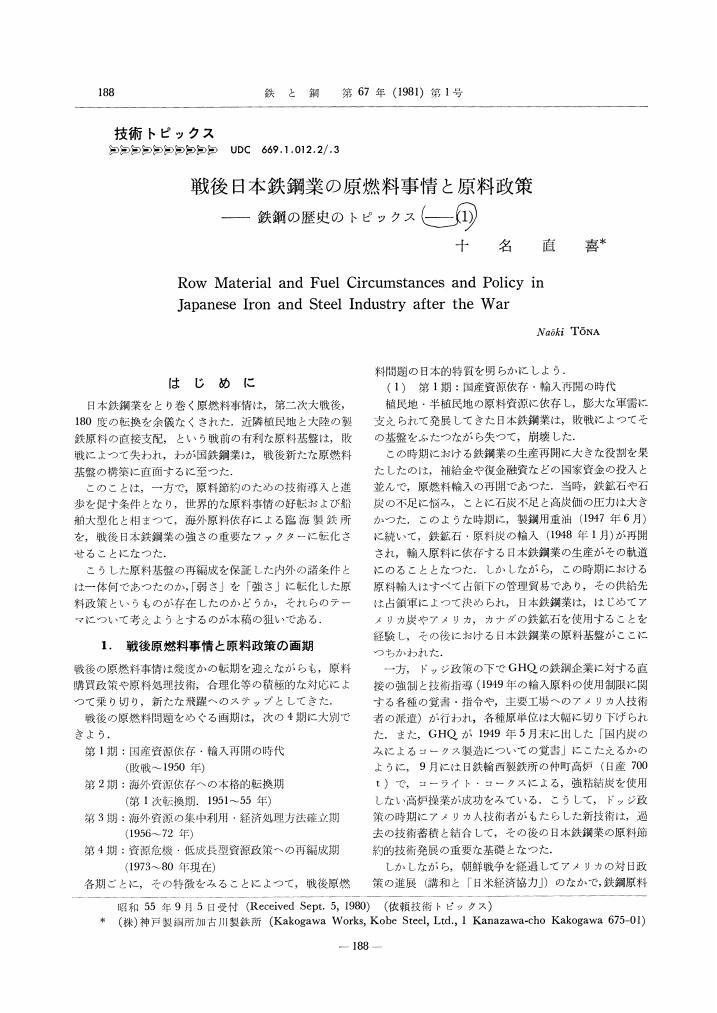

1 0 0 0 OA 戦後日本鉄鋼業の原燃料事情と原料政策

- 著者

- 十名 直喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.1, pp.188-191, 1981-01-01 (Released:2009-06-19)

- 被引用文献数

- 1

1 0 0 0 OA 低温度に於ける鋼材の特性

- 著者

- 長谷川 正義

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.41, no.4, pp.451-468, 1955-04-01 (Released:2010-01-19)

- 参考文献数

- 117

- 被引用文献数

- 1 1

1 0 0 0 OA 各種チタン合金の破壊靱性におよぼす温度と加工誘起変態の影響

- 著者

- 小林 俊郎 新家 光雄 稲垣 育宏

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.3, pp.537-544, 1989-03-01 (Released:2010-01-18)

- 参考文献数

- 16

- 被引用文献数

- 1 1

It is highly expected that the ductility and toughness of titanium alloys bearing unstable β phase may be developed by the stress relaxation caused by strain-induced transformation. In this study, tensile test, Charpy impact test, static and dynamic fracture toughness tests were carried out at various temperatures on typical titanium alloys bearing unstable β phase. The strain-induced α″ martensitic transformation occurred in the (α+β) type Ti-6Al-2Sn-4Zr-6Mo alloy and the dynamic fracture toughness of this alloy increased considerably at 223 K. The strain-induced α' martensitic transformation occurred in the (α+β) type Ti-6Al-4V alloy, and the static and dynamic fracture toughness increased considerably at 123 and 223 K respectively and strength increased at low test temperatures in this alloy. The mechanical twin occurred in the β type Ti-15V-3Al-3Sn-3Cr alloy and the elongation of this alloy increased considerably at 123 K.

1 0 0 0 OA 溶銑予備処理技術の開発,発展の歴史と将来展望

- 著者

- 小川 雄司 丸岡 伸洋

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.4, pp.434-444, 2014 (Released:2014-03-31)

- 参考文献数

- 92

- 被引用文献数

- 8 15

Progress of hot metal treatment technology in Japan and scientific researches which supported the technology are outlined.To meet the increasingly severe customer requirements for steel properties, integrated steelmakers developed technologies for purifying molten steel, centering on the divided refining process, consisting of hot metal treatment, BOF decarburization and secondary refining. The hot metal treatment processes were put into practice at almost all steelworks in the 1980 s.Since the 1990 s, all companies have improved and restructured the hot metal treatment facilities, aiming at not only improvement of refining efficiency so as to achieve a higher degree of purity steel with higher productivity at lower cost, but also reduction in slag volume with the environmental problems taken into consideration.The directions in which hot metal treatment technology is to be pursued in the future are also commented briefly.

1 0 0 0 OA 韓国の鉄スクラップ需要予測

- 著者

- 玉城 わかな 五十嵐 佑馬 藤巻 大輔 林 誠一 友田 陽 松野 泰也 長坂 徹也

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.92, no.5, pp.340-345, 2006-05-01 (Released:2009-06-19)

- 参考文献数

- 20

- 被引用文献数

- 6 6

1.91 milliont of steel scrap was exported from Japan to Korea in 2003, which accounted for more than 30% of the total steel scrap exported to other countries from Japan. Change in steel scrap demand in Korea in the future will make a great influence on the amount of Japan's steel scrap domestic consumption and export. In this work, quantitative data about the steel production, steel scrap demand and consumption during 1977-2003 in Korea were collected to analyze the amounts of inhouse, industrial and obsolete scrap generation, and total steel accumulation in Korea. Then, the steel scrap demand in Korea in the future was estimated. The total accumulation of steel in Korea was estimated as 380 million t in 2003 and 548 million t in 2010, respectively. The amount of obsolete scrap generation in Korea was 7.1 million t in 1996 and 9.0 million t in 2003, which was about 3.0% and 2.4% of the total steel accumulation in each year. Supposing that the amount of crude steel production, scrap consumption percentages in B.O.F and E.A.F will be stable, the obsolete scrap generation in Korea in 2010 were estimated as 13-17 million t. This significant increase in obsolete scrap generation in Korea could exceed the current amount of the scrap import. So, self-sufficiency of steel scrap could be achieved in around 2010 in Korea.

1 0 0 0 OA 神戸第2高炉(3次)の吹き止め操業及びN2冷却保存

- 著者

- 西田 功 田中 孝三 上原 輝久 矢場田 武 高野 成

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.2, pp.189-196, 1985-02-01 (Released:2009-06-19)

- 参考文献数

- 14

- 被引用文献数

- 1

No. 2 blast furnace in Kobe Works was blown in on February 4, 1981 and because of the economic conditions it was blown out on April 22, 1983. Since its working period was very short (about 2.2 years), it was banked with the expectation of blowing in after several years.The methods employed were :(1) to lower the stock line down to just above the level of the SiC brick lining (lower shaft) with the burden being replaced by coke, (2) to cool the furnace by N2 gas, (3) to preserve the furnace brick under N2 atmosphere.Two samples of SiC brick at lower shaft part were collected just after and at 8 months after blowing out, and then they were investigated. It was found that there was no impairment in the SiC brick during this 8-month period.Hot stoves were cooled by the natural cooling method with keeping airtight and their cooling periods were about 3 months. After cooling them, the observations inside them were done and it was confirmed that the damage of the brick was very little, so the reoperation of them would be of no trouble.

1 0 0 0 OA 鉄鋼技術の進歩発展と将来展望

- 著者

- 三好 俊吉

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.81, no.11, pp.N534-N540, 1995-11-01 (Released:2009-06-19)

- 著者

- 横井 龍雄 首藤 洋志 池田 賢一 中田 伸生 土山 聡宏 大村 孝仁 峯 洋二 高島 和希

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.5, pp.244-252, 2016 (Released:2016-04-30)

- 参考文献数

- 38

Dual Phase (DP) steel is used in automotive body parts for weight saving and crashworthiness, however there is an issue of DP steel in low stretch flange ability evaluated by hole expanding tests. In order to improve stretch flange ability of DP steel, it is important to estimate the damage of punching quantitatively and to clarify the change of microstructure before and after punching because the hole expansion ratio is decided in the ductility remained after pre-strain equivalent to punching. Therefore we tried to measure the damage of punching by unique techniques of Electron Backscatter Diffraction (EBSD), nano-indentation and micro-tensile testing and to observe fracture surface by Scanning Transmission Electron Microscope (STEM). Average EBSD-Kernel Average Misorientation (KAM) value and pre-strain damage have strong correlation, thus average KAM value can become the index of the damage. The nanohardness and tensile strength using micrometer-sized specimens increased with increasing average KAM value in the ferritic phase as approaching the punching edge. A shear type fracture occurred without necking in the specimen cut out in the area of the edge. The ultrafine-grained ferritic microstructure was observed in the sample cut out in the same area with STEM. It seems that the ductility loss of the punched DP steel was probably attributed to localized strain into the ultrafine-grained ferritic microstructure.

1 0 0 0 OA 昭和35年を鉄鋼技術躍進の年とせよ

- 著者

- 絹川 虚舟

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.46, no.4, pp.453-454, 1960-04-01 (Released:2010-10-12)