1 0 0 0 OA サテライトミルによる平線およびT形異形線の圧延

- 著者

- 齋藤 好弘 宇都宮 裕 平田 健二 岡 景則

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.83, no.7, pp.431-436, 1997-07-01 (Released:2009-06-19)

- 参考文献数

- 3

- 被引用文献数

- 1 1

The authors have developed a new type rolling mill named the satellite mill. The mill comprises one large diameter roll (central roll) and five smaller diameter rolls (satellite rolls) arranged along a circumference of the central roll. Material is passed continuously through the five gaps between the central roll and the satellite rolls and deformed into a profiled cross section. Since all rolls are driven at the same roll speed, longitudinal compressive stress is produced between stands during rolling. The elongation is greatly suppressed. The mill has been applied to the production of round-edged flat wires and two kinds of T-shaped profiled wires from round circular wires. The obtained rolling characteristics and product properties are compared with those by a conventional rolling method. It is shown that the transverse metal flow is enhanced and the filling ability to the roll groove is excellent in satellite-mill rolling. The effect is more apparent in rolling of T-shaped wire having thinner ribs. It is supposed that the satellite mill is favorable for profiled wire production.

1 0 0 0 OA 鉄鋼材料における合金元素の活用の変遷と将来展望

- 著者

- 潮田 浩作 吉村 仁秀 海藤 宏志 木村 謙

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.6, pp.716-727, 2014 (Released:2014-05-31)

- 参考文献数

- 67

- 被引用文献数

- 7

Steels have made remarkable progress in order to meet the strict requirements of today’s society. Such progress is based on scientific elucidation of the functions of alloying elements, their effective utilization, and the innovative production processes.Since natural resources are limited, it is important to increase their productivity for the continuous development of our society. Therefore, proper management taking into account the element strategy is becoming extremely important.Steel industries are highly dependent on rare metals. Therefore, they are easily influenced by the hazards of rare metals, avoidance of which is extremely crucial.This paper focuses on steels such as flat-rolled product, plate, pipe & tube and stainless steel, and historically reviews them from the aspect of changes in the surrounding market together with the technological developments such as new steel products and exploitation of rare metals for them. The functions of rare metals are classified into three types, i.e. the control of a) microstructures, b) mechanical properties and c) anti-corrosion properties, and the present understanding of them is discussed from a scientific perspective. Furthermore, the concrete future scientific and technological problems are surveyed. It is revealed that there are still many issues that need to be addressed. Exploitation of the advanced analytical techniques together with computational science is expected to contribute to solving the long standing problems and to stimulate a breakthrough in this field.

- 著者

- 秋山 英二 李 松杰 片山 英樹 張 波萍 趙 楷 押川 渡

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.103, no.2, pp.93-100, 2017

<p>Electrochemical hydrogen permeation tests were carried out under controlled temperature and humidity using pure Fe sheet specimens outdoor-exposed at Beijing and Chongqing, China and Okinawa, Japan in order to understand the effect of environmental factors on hydrogen uptake behavior. The maximum hydrogen permeation current densities of the exposed specimens were in the order of Beijing > Chongqing >> Okinawa, while the order of the degree of corrosion of the specimens was Okinawa > Chongqing >> Beijing. X-ray fluorescence analysis showed that the surface concentrations of sulfur on the Beijing- and Chongqing-exposed specimens were higher than that of the Okinawa-exposed specimens, whereas chlorine concentrations of the Beijing and Okinawa-exposed specimens were higher than that of the Chongqing-exposed specimen. Nitrate concentrations of Beijing- and Chongqing-exposed specimens evaluated using nitrate test strips were obviously higher than that of the Okinawa-exposed specimens. It is suggested that air pollutants such as SO<sub>2</sub> and NO<sub>2</sub> and particulate matters containing inorganic acid ions, likely sulfate and nitrate ions, and possibly organic acids contribute to acidification of rust layer leading to the enhanced hydrogen entry.</p>

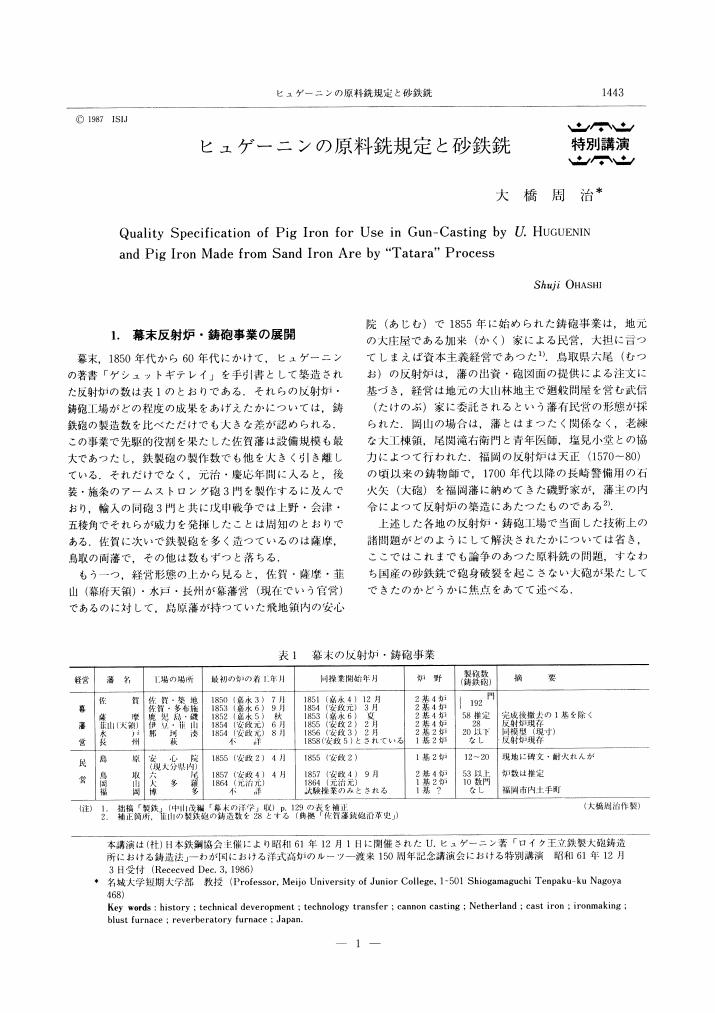

1 0 0 0 OA ヒュゲーニンの原料銑規定と砂鉄銑

- 著者

- 大橋 周治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.11, pp.1443-1452, 1987-09-01 (Released:2009-06-19)

- 参考文献数

- 12

1 0 0 0 OA 最近のチタンの溶解技術およびチタンインゴットの品質問題とその解決法

- 著者

- 小泉 昌明

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.74, no.2, pp.215-223, 1988-02-01 (Released:2009-05-29)

- 参考文献数

- 38

- 被引用文献数

- 3

1 0 0 0 OA フェライト・ステンレス鋼の遷移温度と475℃脆性におよぼす不純物元素の影響

- 著者

- 長谷川 正義 武田 克彦 竹下 一彦

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.9, pp.1353-1362, 1974-08-01 (Released:2010-10-12)

- 参考文献数

- 10

- 被引用文献数

- 2 2

The brittle-to-ductile transition curves of a series of ferritic stainless steels containing carbon, nitrogen, silicon or manganese, respectively, were determined, and also the effect of aging at 475°C on the transition curves of high purity ferritic stainless steels was discussed.The main results obtained were as follows:(1) In 18% chromium steels, at the 0.002% carbon and 0.004% nitrogen levels, the indicated transition temperature is found to be 85°C However, there is a remarkable increase in transition temperature and a decrease in upper shelf energy, as carbon or nitrogen content increases. The effect on transition temperature and upper shelf energy is attributed to the exsistence of solute carbon or nitrogen atoms and the dispersed carbide or nitride precipitates.(2) Addition of aluminium as stabilizer is effective in lowering transition temperature.(3) Silicon and manganese additions tend to raise transition temperature.(4) In high purity 18% chromium steel aged at 475°C the upper shelf energy decreases, but the transition temperature has little change.(5) In 0.05% nitrogen-18% chromium steel aged at 475°C, the upper shelf energy decreases, and the transition temperature is shifted toward higher temperatures.(6) The hardness increase with the aging time for high purity 18% chromium steel is less than for 0.05% nitrogen-18% chromium steel.(7) These phenomena caused by aging at 475°C must be depended on the precipitation of chromium rich bcc phase and chromium nitrides.

1 0 0 0 OA 圧力容器用鋼の応力除去焼なまし処理に伴う機械的性質の変化

- 著者

- 勝亦 正昭 小出 憲司 梶 晴男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.2, pp.353-360, 1989-02-01 (Released:2009-06-19)

- 参考文献数

- 15

- 被引用文献数

- 2

Prolonging annealing treatment below the critical temperature is carried in order to relieve residual stress due to welding and to improve toughness of weld heat affected zone in the fabrication of pressure vessels. It has been known that this treatment named stress relief (SR) annealing decreases strength and toughness of base metals. Thus, the effects of microstructure and alloying elements on this decrease in mechanical properties were investigated in carbon-manganese, manganese-molybdenum and chromium-molybdenum steels for pressure vessels.The decreasing amount of strength and toughness due to SR annealing was the largest in martensite structure and next in bainite structure. These was little change in strength and toughness in ferrite-pear-lite structure. Good toughness was obtained by SR treatment at high temperature and for short time in comparison with that of low temperature and long time at a certain strength. The start of decreasing toughness was delayed by an increase in {1/5 (Mn(%)+ Cr(%))+Mo(%)} content.Applied stress equivalent to residual stress level in SR treatment did not affect mechanical properties. The amount of temper embrittlement due to slow cooling in SR treatment decreased with prolonging SR treatment.

1 0 0 0 OA 連続冷却途中での冷却速度変更にともなうパーライト変態挙動

- 著者

- 清水 信善 田村 今男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.61, no.10, pp.2375-2390, 1975-08-01 (Released:2010-10-12)

- 参考文献数

- 13

- 被引用文献数

- 4

In this investigation, the pearlitic transformation behaviour of steel with the cooling rate discontinuously altered during continious cooling was studied in relation to the CCT diagram of the steel. The main results are as follows:(1) The pea litic transformation behaviour with the cooling rate discontinuously altered during continuous cooling was diffe-ent from the transformation behaviour illustrated by usual CCT diagram.(2) The pearlitic transformation behaviour and the critical cooling rate with the cooling rate altered at a point during continuous cooling were observed to be related to the incubation period consumed before changing the cooling rate.(3) Including the degree of consumed incubation period in usual CCT diagram as a parameter, the transformation behaviour and the critical cooling rate can be estimated from a conventional CCT diagram.(4) If the same amount of the incubation period was consumed by either continuous cooling or isothermal holding, the transformation behaviour was virtually the same in subsequent cooling when the cooling started from the same temperature.

1 0 0 0 OA ISO鉄鉱石物理試験専門委員会の近況/第二次世界大戦中における製鋼技術の開発研究

- 著者

- 前田 一徳 堀川 一男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.3, pp.488-491, 1983-03-01 (Released:2009-06-30)

1 0 0 0 OA シリコン結晶中の酸素の挙動

- 著者

- 井上 直久 和田 一実

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.8, pp.947-955, 1987-06-01 (Released:2009-06-19)

- 参考文献数

- 40

1 0 0 0 OA Fe-Mn-C-Al TWIP鋼の水素脆化における静的および動的ひずみ時効の影響

- 著者

- 小山 元道 秋山 英二 津﨑 兼彰

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.9, pp.1132-1139, 2014 (Released:2014-08-31)

- 参考文献数

- 36

- 被引用文献数

- 4

Al effects on strain aging and resistance against hydrogen embrittlement were examined in Fe-18Mn-0.6C-based twinning-induced plasticity steels deformed at different strain rates. The Fe-18Mn-0.6C steel showed hydrogen-induced fracture when it had been pre-deformed at a strain rate of 1.7×10–6 s–1. The hydrogen-induced fracture was suppressed by increasing strain rate and increasing Al content. From the viewpoint of material strengthening by strain aging, we found two important factors improving the resistance to the hydrogen embrittlement; (1) suppression of dynamic strain aging by increasing strain rate and Al content, and (2) suppression of static strain aging under loading by the Al addition.

1 0 0 0 OA ロケット用複合材料の現状と展望

- 著者

- 垣見 恒男 佐藤 博

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.14, pp.1659-1665, 1984 (Released:2009-06-30)

- 参考文献数

- 25

1 0 0 0 OA たたら製鉄炉地下構造における小舟の役割

- 著者

- 永田 和宏 羽二生 篤 鈴木 卓夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.87, no.10, pp.665-672, 2001 (Released:2009-06-19)

- 参考文献数

- 15

- 被引用文献数

- 2

The Tatara is the traditional iron-and steelmaking process in Japan. The box type furnace is about 1 m width, 3 m length and 1.2 m height. The process produces steel bloom and pig iron from iron sand and charcoal. The furnace is built on the charcoal bed in a big underground construction which is separated into upper and lower parts by a thick clay layer, "Kobune Kawara". The lower part is a drainage. The upper part has a charcoal bed, "Hondoko", with twin caves, "Kobune", on the both sides. The "Kobune" keeps its temperature lower than 41°C and humidity higher than 89%, that is, 4.8×10-2kg·m-3 in terms of water vapor concentration, during "Tatara" operations. The heat flow and temperature distribution around the furnace during operation was numerically simulated. The water vapor in "Hondoko", hearth and "Doi" flows to "Kobune" according to heat flow and disperses to the surroundings. Further the historical development of underground construction is discussed.

1 0 0 0 OA 住友金属 鹿島製鉄所 第2冷間圧延設備について

- 著者

- 重松 健二郎

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.81, no.2, pp.N66-N69, 1995-02-01 (Released:2009-06-19)

- 参考文献数

- 8

- 被引用文献数

- 1

1 0 0 0 OA 定温加熱・鋼中フリー窒素定量法における微粉試料の時効と影響

- 著者

- 滝沢 佳郎 畑 俊彦 遠藤 芳秀

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.16, pp.2301-2304, 1984-12-01 (Released:2009-06-30)

- 参考文献数

- 8

Determination of free nitrogen in steel by constant temperature-hydrogen hot extraction method was studied and optimum analytical conditions were established.1) Lower measured values were obtained with samples that had passed for long time after powdering. 2) The result of 1) was considered to come from the fact that dissolved nitrogen in steel was locked to dislocations and/or formed cluster gradually, thus becoming difficult to be extracted. 3) Higher temperature of environment around samples accelerated these effects, so it must be avoided to heat powdered samples for washing and drying. 4) It is necessary to analyse samples of finer powders soon after powdering. 5) When the sample was analysed under these analytical conditions, free nitrogen could be fully extracted at 400°C.

1 0 0 0 OA 最近の製鋼用アーク炉設備と溶解技術の動向

- 著者

- 野田 孝昭 和泉 喜久磨

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.77, no.6, pp.723-734, 1991-06-01 (Released:2009-06-19)

- 参考文献数

- 20

1 0 0 0 9%Ni鋼の破壊靱性に及ぼすき裂先端における温度上昇の影響

- 著者

- 佐野 謙一

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.2, pp.380-386, 1987

- 被引用文献数

- 2 7

The effect of loading rate on fracture toughness of 9% Ni steels with four levels of Charpy absorption energy was studied at various loading rates between impact and static at -196°C. In contrast to the ordinary ferritic steel, the fracture toughness of 9% Ni steel was foud to increase with the loading rate above 20mm/min. The transition of the fracture mode from brittle to ductile took place at the loading rate of 100mm/min, the fracture was completely ductile above this level. The dynamic fracture toughness, <I>K</I><SUB>d</SUB>, was greater than the static one, <I>K</I><SUB>c</SUB>. These observations are attributed to the temperature rise at a crack tip during the adiabatic heating at high strain rate, which is emphasized by decreased specific heat and the thermal conductivity at -196°C. The temperature rise during the fracture was measured by a Cu-Constantan thermocouple, and was in good accordance with the previous theoretical prediction. The observed maximum temperature rise was 188°C. The results suggest that not only in 9% Ni steel but in other metals and alloys as well the effect of temperature rise at a crack tip can be an important factor in the dynamic fracture.

1 0 0 0 OA 連鋳鋳片の表面性状に及ぼす磁気圧力の効果に関するモデル実験と理論解析

- 著者

- 鷲見 郁宏 佐々 健介 浅井 滋生

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.78, no.3, pp.447-454, 1992-03-01 (Released:2009-05-29)

- 参考文献数

- 11

- 被引用文献数

- 3

Being aimed to improve the surface quality of a continuously cast steel, a new electromagnetic casting method is proposed where the high frequency magnetic field is imposed on the initial stage of solidification from the outside of a mold. The magnetic pressure induced by the magnetic field provides the solidification taking place under the soft contacting pressure of molten metal with the mold, so called soft contacting solidification. Molten tin was cast by imposing magnetic field with 1.75, 3.75 and 15.4 kHz frequency in order to examine the applicability of the method to the cast of steel. It is found that this electromagnetic casting method has a potential to be applied to the cast of steel. The stronger intensity of magnetic field could provide the better surface quality of products in the way of reducing oscillation marks. However, the excess intensity of magnetic field caused the disturbance on meniscus inducing surface defects. The critical intensity of magnetic field at which the surface defects due to fluid disturbances at meniscus appeared increased with increasing the frequency of magnetic field. It is noticed that the effect of magnetic field on reduction of surface defects appears more significantly when mold oscillation was not applied than when the oscillation was applied.

1 0 0 0 OA 二相ステンレス鋼の変形エネルギーに及ぼす引張試験片板厚の影響

- 著者

- 平島 拓弥 荒牧 正俊 山本 正之 安田 恭野 宗藤 伸治 古君 修

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.101, no.5, pp.308-314, 2015 (Released:2015-04-30)

- 参考文献数

- 12

- 被引用文献数

- 7 6

Effect of specimen thickness on ductile fracture energy for ferrite-austenite duplex stainless steel was investigated by using tensile strain test. It was revealed that both uniform and local deformation energies decreased with the decrease in the specimen thickness. Voids in a thicker specimen can be easily formed at the lower plastic equivalent strain because of the steep increase in the triaxiality. The decrease in the local deformation energy was due to the void growth near the fracture surface depending on the steep increase in the stress triaxiality.

1 0 0 0 OA 鋼板の成形性/被削性・疲労

- 著者

- 飯田 博孝 佐藤 完往 川瀬 尚男 中川 威雄 吉田 清太 加藤 健三 花木 香司 岩根 窓一郎 小門 統一 小野田 義富 松藤 和雄 内田 恭彦 大沢 紘一 泉 稔一 沢井 巌 貝田 邦儀 渡辺 就市 八杉 誠二郎 中尾 信彦 牧野 武久 萩原 康禎 金田 次雄 柳 義親 山上 徹 山口 喜弘 成田 貴一 田阪 興 赤沢 正久 黒岩 和也 野崎 輝彦 大西 稔秦 菅原 宏文 細井 信彦 武田 三雄 浜端 進 吉田 鎮雄 木村 篤良 加藤 剛志 荒川 武二 山本 俊郎 相沢 武 日下 邦男 岩丸 正明 荒木 透 石 茲宜 佐川 竜平 角田 方衛 内山 郁

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.56, no.11, pp.S513-S522, 1970-09-05 (Released:2010-10-12)