1 0 0 0 OA 湿潤紙力増強剤の強度発現機構

- 著者

- 牧野 重人

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.52, no.12, pp.1710-1716, 1998-12-01 (Released:2009-11-19)

Some applications such as tissue papers or filter papers require strength at wet even though paper orginally has weakness to water. For these applications, wet strength agents that meet such requirement are added to papers at the stage of pulp slurry.Namely, we have polyamide resin or melamine resin for the additives that give paper strength at wet. The main reasons polyamide is suitable for the application are that it can give high wet strength with a little amount of the resin, it can be used in a wide pH range, and it does not contain formaldehyde. Melamine resin is also suitable for the application because of early appearance of wet strength after drying stage in papermaking, dimensional stability, alkali resistance, and ultraviolet-ray resistance.Dry strength of paper largely depends on hydrogen bond among cellulose molecules. Invasion of water among fibers cause the destruction of the hydrogen bond. The wet strength expression mechanism of the polyamide resin apply to the prevention of water infiltration to fiber crossing made by crosslinked resin in drying process of papermaking. On the other hand, that of melamine resin apply to a strong water-resistant bond of methylol group in the resin between hydroxyl groups of the cellulose.For the sake of effective usage of wet strength agents, we should keep the following important points in mind. First, enough heating is necessary for the expression of wet strength as wet strength agents are thermosetting. Secondly, since cation resin electrically interacts with anionic fiber, existence of anionic trash and salts decrease in the resin retention. At last, excessive addition of wet strength agents can cause decrease in the resin retention, pitch trouble, bubbling, increase in drain loading, and etc.

1 0 0 0 OA 紙の劣化速度に関する検討

- 著者

- 尾関 昌幸 大江 礼三郎 三浦 定俊

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.39, no.2, pp.233-242, 1985-02-01 (Released:2009-11-16)

- 参考文献数

- 4

- 被引用文献数

- 3 3

Durability of papers, such as acid and neutral wood free papers, Japanese Kozo (Broussonetia papyrifera) and Gampi (Wikstroemia retusa) papers, as well as handsheets from Mitsumata (Edgeworthia papyrifera), Kozo, Manila hemp and softwood sulphate pulps, were compared by means of degradation rate or relative durability obtained from Arrhenius plots of folding endurance at various temperatures and relative humidities. It was confirmed that papers or handsheets from bast fibres for Japanese paper-making were less degradable compared with those from wood pulps.Influences of acidity and sulphate ion concentration at handsheet making were also investigated. It was not perceivable that sulfate ion concentration was adversely so effective to durability of paper as acidity, which deteriorated properties of papers from bast fibres as well as from wood pulp.

1 0 0 0 OA 紫外線と過酸化水素を併用した各種家庭紙の殺菌及び抄紙工程排水の殺菌

- 著者

- 吉野 潔 岩崎 達行 小野 健一郎 町田 三一 木下 忍 松原 淳 室谷 正次 西尾 紀昭 安井 俊彦

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.53, no.10, pp.1345-1352, 1999 (Released:2009-11-19)

To control the generation of “(*slime*)” which became a problem when the papermaking process drain was reused, we examined sterilization tests by using ultraviolet (UV) radiation and hydrogenperoxide (HP) together. It was confirmed general bacilli was able to be sterilized by changing the amount of the UV radiation and the amount of the addition HP at an arbitrary level and the proliferation control was effective.Next, we examined the number of general bacilli which existed together on the household papers, such as toiletpapers and tissues. Hundreds of general bacilli a piece in toiletpapers detected and tens of it a piece in tissues. When the UV radiation was irradiated to these papers, it was understood not to detect a general bacillus by one side 30 (mj/cm2) level if both sides were irradiated. When UV radiation was irradiated after HP do atomization, it was confirmed to be able to sterilize even with the HP a low density and the amount of the UV radiation of a low level. Sterilization and the water processing technology by UV radiation and HP using together are thought to be a technology which can be used by various scenes of the papermaking process.

1 0 0 0 岩国工場コーター操業経験

- 著者

- 金子 豊

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.55, no.12, pp.1717-1721,016, 2001

日本製紙岩国工場は, 1937年にパルプの生産から始まり, 平成9年のオンマシンコーターである9マシンの完成により, 現在, 上質紙, 上質コート紙を主体に65万トン/年の生産があり, この内コート紙は70%を占めている。<BR>工場にはコート紙製造設備として, 4, 5コーター, 9マシンの他に感熱原紙, 感圧紙抄造の3マシン, 1,2キャストコーターがある。<BR>上質コート紙を抄造する先の3台のコーターでは, その操業性改善の為岩国工場独自で取り組んできた設備が設置, 稼動している。<BR>(1) 操業中も使用可能な, パッキングロール自動サンディング装置<BR>(2) カラー排水処理専用のサイクルヒット設備<BR>(3) オフマシンコーターのスプライステープ検出装置等, コーター及び工場の操業安定に貢献している。

- 著者

- 森 大之 藤本 康之 貴船 博巳 竹中 寿康 大岩 修 稲田 治

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.48, no.1, pp.78-82, 1994

Our Cycle Hit System of Iwakuni Mill started up from Febrary 1993 and Coated paper product waste liquor (Color waste liquor) has been treated succesfully with it.<BR>In this system, primary plus secondary sludges are directed to a slugde conditioning tank, where it is dosed with an inorganic coagulant and mixed to neutralize the surface charge of the sludge particles.<BR>This conditioned sludge is then sent to a pelletizing/thickening tank, where an anionic and an amphoteric polymers are added to pelletize the sludge. Using the same tank, water can be removed with a special built-in device, resuluting in a sludge with an increased concentration of solids.<BR>This report described the summary of operation.

1 0 0 0 OA 感熱記録紙の現状と技術動向

- 著者

- 藤村 章夫 佐竹 寿己

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.40, no.10, pp.899-912, 1986-10-01 (Released:2010-10-27)

- 参考文献数

- 20

- 被引用文献数

- 1

1 0 0 0 OA 古紙パルプ漂白技術の基礎

- 著者

- 腰塚 哲夫

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.56, no.7, pp.963-975, 2002-07-01 (Released:2009-11-19)

- 参考文献数

- 12

- 被引用文献数

- 1 2

The amount of production of the hydrogen peroxide in the year 2000 was 145, 744 t. The demand for pulp is 71, 237 t and the ratio has reached 48. 9%. Also, about 60% of the demand for this pulp has been estimated as demand for recycled pulp. Therefore, recycled pulp is an important field of the hydrogen peroxide market.Seven kinds of oxidizing agent (chlorine, hypochlorite. chlorine dioxide, hydrogen peroxide, oxygen, ozone, peracetic acid), three kinds of reducing agent (sodium hydrosulfite, sodium borohydride. formamidine sulfinic acid) were described and especially hydrogen peroxide, sodium hydrosulfite, and formamidine sulfinic acid were described in detail as important bleaching agent.Concerning hydrogen peroxide, the influence of metals, the heat of kneader and catalase were described. The preventative measures were also described.Concerning sodium hydrosulfite, the decomposition by air, water and combustion by water were described. As a measure, “HS master”, which can dissolve sodium hydrosulfite continuously in nitrogen gas atmosphere and can feed it to the pulp bleaching site was introduced. “HS master” was developed by Mitsubishi Gas Chemical.Concerning formamidine sulfinic acid, the “Fosble System” which is able to manufacture it on-site was introduced. The “Fosble System” was developed by Mitsubishi Gas Chemical.

1 0 0 0 製紙機械の安定した連続運転を実現する合成潤滑油

- 著者

- ワイス ピーター エリオット ステファン 高野 聡 笠井 隆志

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.55, no.10, pp.1452-1456,025, 2001

今日, 合成潤滑油の優れた面に関する漠然とした理解があり, その一方で, 合成潤滑油を製紙機械に使用した場合, 経費節減をもたらすという現実がある。<BR>本報の目的は, 合成潤滑油の使用に関する理解を深め, 合成潤滑油の製紙機械への適用の手だてとしていただくことである。まず「合成」という言葉を説明し, 異なった特長を持つ, さまざまな合成潤滑油の種類について紹介する。合成潤滑油の特長は, 下記の通りである。<BR>(1) 優れた粘度温度特性,(2) 高い熱・酸化安定性,(3) 優れた流動特性,(4) 鉱物油との親和性 (特にポリアルファオレフイン),(5) オイル交換周期の延長,(6) 摩擦損失の低減,(7) オイル消費量の低減<BR>また, 合成潤滑油がもたらす利益についての技術的なアドバイスと, その製紙機械の適用箇所を見つける方法について述べる。<BR>合成潤滑油が鉱物油と比較して, いかに経費節減に貢献するかについて, 具体的な適用例を取り上げながら説明する。本報が, 実際に製紙機械の運転や管理に携わる方々の経費節減のヒントに繋がることを望む。

1 0 0 0 OA 王子製紙株式会社富岡工場

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.56, no.3, pp.406-415, 2002-03-01 (Released:2009-11-19)

1 0 0 0 OA 工場紹介 (15)

- 著者

- 株式会社巴川製紙所

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.33, no.10, pp.648-653_1, 1979 (Released:2009-11-10)

1 0 0 0 フルグライドコーティングによる水ポンプの省エネルギー化

- 著者

- 水野 剛

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.68, no.7, pp.726-733, 2014

電力供給状況の変化が見込まれる昨今において,製造工場における回転機械の消費電力削減の意義は大きい。しかしながら,多くの回転機械において現状の消費電力値や効率が最適値であるかどうかを判断する方法はほとんど存在しない。そこで英国Corrocoat社及びコロコートジャパン株式会社は,水ポンプに特化して,現状のポンプ効率を定量化するための計測装置ならびに演算処理方法を確立した。これにより現状の消費電力やポンプ効率が可視化され,製造時と比較した際の現状の劣化レベルを定量化することができるようになった。ユーザーは定量化された劣化レベルから,補修対象や適切な補修処理を判断することができるようになった。また補修処理のための投資に対する補修による効果の事前検証も可能となった。<BR>次なる命題は,劣化した水ポンプをどのように補修し,どのように高効率化するかである。従来の水ポンプの補修は,タールエポキシに代表される部分補修であったが,耐久性に乏しく,水ポンプの高効率化実現に直接つながることはなかった。その状況を鑑み,1986年にCorrocoat社は水ポンプの高効率化を実現するフルグライドコーティングの開発に成功した。同コーティングの適用により,製造時に比べ10%近く低下したポンプ効率は製造時と同等か,それ以上まで回復した。ポンプ効率の上昇は消費電力の削減につながるために,フルグライドコーティング施工で年間数百万円の損失を回避することができた事例が数多く出てきた。<BR>本稿においては,海外・国内における性能計測やコーティング適用事例や統計データを紹介し,ポンプ効率低下の傾向や,フルグライドコーティングの確度を実証する。

1 0 0 0 OA 紙類の規格制定の発端とその経緯 (1)

- 著者

- 米谷 稔

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.32, no.9, pp.495-503, 1978-09-01 (Released:2009-11-10)

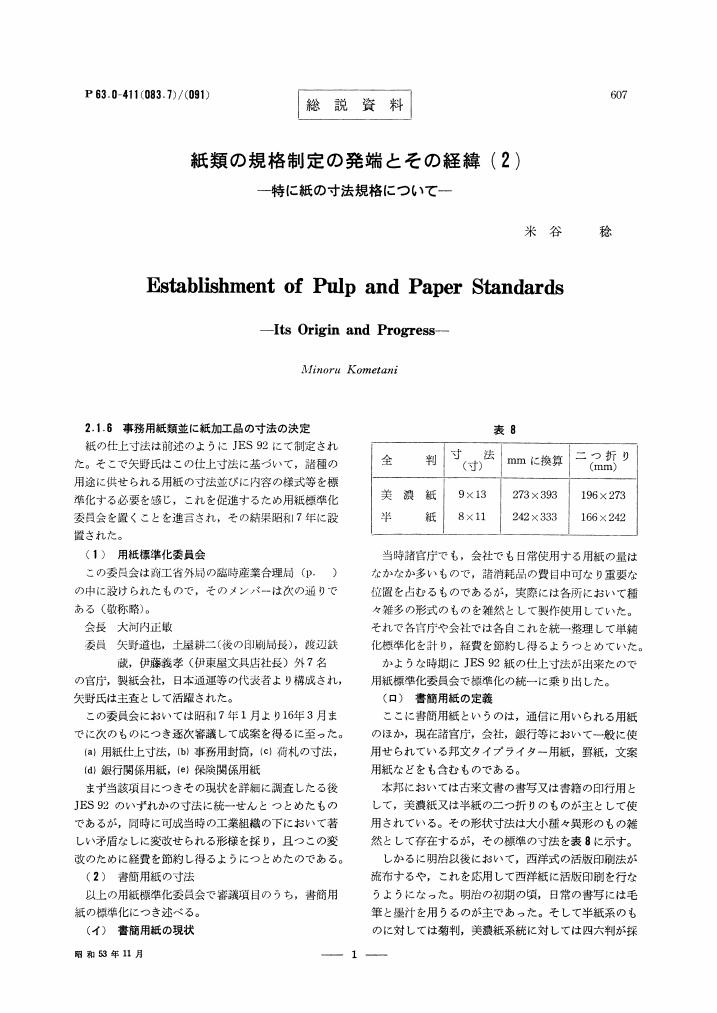

1 0 0 0 OA 紙類の規格制定の発端とその経緯 (2)

- 著者

- 米谷 稔

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.32, no.11, pp.607-618, 1978-11-01 (Released:2009-11-10)

1 0 0 0 OA パルプ中の多糖類に関する研究

- 著者

- 戸田 久昭 浜田 忠平

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.12, no.5, pp.324-328, 1958-05-10 (Released:2009-11-17)

- 参考文献数

- 7

In order to determine the composition of polysaccharides of pulp, E. Hägglund proposed a procedure of total hydrolysis of pulp, and later various modified procedures of his one were applied by many investigators. In the present paper, occurence and decomposition of monosaccharides during the total hydrolysis have been investigated by means of paper chromatographic technique.From this investigation, it has been found that a procedure of total hydrolysis is enough to complete the hydrolysis of cellulose, which consists of a primary hydrolysis for 1 hr. at 30°C with 72 % H2SO4 and a secondary one for 6 hrs. with boiling diluted (4.0 %) H2SO4. But hydrolysis of xylan and mannan had already been completed within 4 hrs. secondary hydrolysis.When much glucose in hydrolysate interfere the spot of mannose on the paper strip, it is recommended to use glucose oxidase, 10 mg of which can oxidize 10 and 50 mg of glucose within 5 and 20 hrs. respectively (pH 7.0, 37°C).Water soluble polysaccharides (γ-cellulose) in pulp were completely hydrolyzed by boiling with 4% H2SO4 for 8 hrs. In this case hydrolysis of xylan was also easier than that of mannan and glucan.

1 0 0 0 紙製食品包装容器の蛍光物質溶出検査法について

- 著者

- 宮川 孝 尾松 正元 直原 孝之 新井 直人

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.59, no.2, pp.209-215, 2005

- 被引用文献数

- 3

紙を白く見せるために日常的に蛍光物質 (蛍光増白剤=蛍光染料) が使用されているが, 食品衛生法の食品添加物としての認可を受けていない蛍光増白剤は, 合成着色料の一種として規制され, 検査法としては昭和46年5月8日付厚生省課長通知環食第244号「蛍光物質を使用した器具または容器包装の検査法について」が定められ運用されてきた。<br>02年12月に保健所の検査でタイ製の紙製ビーフントレー (意図的に原紙, 塗工層に蛍光増白剤を添加と推定) より蛍光増白剤の溶出が確認され, 食品の回収命令が出たのが発端となり, 03年7月には蛍光増白剤を意図的に使用していない紙製トレー (古紙配合品) でも回収指導を受ける事態が発生した。このままでは古紙配合製品すべて (白板紙のみならずライナー, 段ボールまで) が回収対象となり, 関係業界を巻き込む大問題に発展する恐れが出てきた。一方, 公定法にもかかわらず指定検査機関間で異なる判定結果となることもわかった。<br>今回, この蛍光物質溶出検査法 (環食第244号) の問題点を抽出し, その原因を明らかにし, この結果をもとに, 日本製紙連合会から厚生労働省に検査法の見直しを03年11月9日に申し入れ, 異例とも言える速さで04年1月7日付厚生労働省課長通知 (食安基発第0107001号・食安監発第0107001号) で検査法が見直され, 判定基準も写真で実例が示されることにより, 古紙配合製品も概ね使用できる見通しとなった。ここまでの経緯と海外の規制状況もあわせて紹介する。

1 0 0 0 OA リグニンの有効利用

- 著者

- 佐田 栄三 浅岡 宏

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.43, no.8, pp.751-767, 1989-08-01 (Released:2009-11-16)

- 参考文献数

- 66

Although lignin in wood materials is to be separated as much as approximately a half of the amount of pulp through pulping processes, currently the chemical value of isolated polymeric lignin has not yet been effectively utilized. It has been desired to develop the processes for utilization of lignin in view of its chemical substance, i.e. highly complex polymer.In this review, first the outline of the present situation of lignin utilization in pulp and paper industries is presented in Section 1. Afterwards, the following three sections have been devoted from the standpoints of effective and potential utilization of lignin : Present situation of utilization of effective components and possibility or potentiality of utilization of derived components as chemical feedstocks (Section 2) Decomposition processes of lignin (Section 3) Possibility of utilization of decomposed components (Section 4).In Section 2, two typical reactions of lignin utilized for separation, i.e. acid catalyzed decomposition of ether likages and reductive decomposition of β-ether have been briefly described and the features of both reaction sequences offered along with practical applications. The necessity to clarify both the decomposition and condensation reactions quantitatively, that is, from the view point of chemical kinetics has been pointed out, because active sites for condensation reaction are apt to be still left after completion of both the reactions. Further, the steam explosion process of lignin, which is a practical process utilizing decomposition reaction of ether linkages is outlined and reactions and separations of derived components are explained to search for a possibility of their effective utilization.The first part of Section 3 is devoted to introduce several trials to degradate lignin chemically and thermally (pyrolysis) for chemical utilization. Hydrogenated decomposition, oxidative decomposition and production of catechol through a nucleophilic substitution reaction are reviewed as to chemical degradation. In the remaining part of this section, the biodegradation of lignin, i.e. the microbiology of lignin degradation, specifically lignin-degrading microbes and enzyme systems of lignin degradation, is reviewed. The latest trend and problems in the relevant fields are outlined and the long-term goals of biological processing of lignin are pressented.In Section 4, a feasibility study for production of polyoxyphenylene (or polyphenylene oxide, PPO) which is an important engineering plastic is given. The production of PPO is regarded as one of the promising processes for utilization of lignin-derived chemicals when the cost of lignin as well as the marcket scale of the product is taken into account.

1 0 0 0 OA 植物バイオテクノロジーの環境問題への応用

- 著者

- 遠藤 さおり 松永 悦子 海老沼 宏安

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.50, no.4, pp.656-666, 1996-04-01 (Released:2009-11-16)

- 参考文献数

- 11

近年の産業の発達に伴い地球規模での様々な環境破壊が引き起こされ, 環境保全が社会全体での課題となってきている。そして, この問題は, 原材料の大半を森林に依存している紙パルプ産業においても, 根幹にかかわる重要な問題であり, 環境保全と産業の発達の調和が, 次世代への持続的な発展への重要な鍵となっている。様々な産業分野において, バイオテクノロジーを用いた技術が, 次世代における産業の発達を可能とする環境保全技術として注目を集めている。紙パルプ産業においても, 植林事業の推進に代表されるように, 環境保全と産業の発達の両面からの事業展開が繰り広げられている。しかし, 次世代において, 企業に対する環境保全の圧力はさらに増大すると推測され, 植林事業においても原材料としてだけではなく, 社会的にも付加価値の高い樹木の植林をおこなうことが必要となると考えられる。バイオテクノロジーの進歩により, 生物に新たな遺伝子を導入することにより, 生物に新たな能力を付加することが可能となってきている。そして, この技術を用い植林木の改良・開発をおこなうことにより, より社会的に付加価値の高い植林事業が可能となると考えられる。本報告では, バイオテクノロジーの中でも, 特に紙パルプ産業と関りの深い, 植物のバイオテクノロジーの環境問題への取り組みとして, 植物の汚染物質の浄化, 解毒に関した研究を紹介する。当研究室において遺伝子組換え技術を用い, 解毒能力を強化した環境ストレス耐性樹木の作成を行っている。遺伝子導入された樹木は, 大気汚染・除草剤などの環境ストレスに対し, 強い耐性を示すことが明らかとなっている。この結果も合わせて報告するとともに, 樹木における遺伝子導入技術の可能性と, 有用性に関し考察する。

1 0 0 0 OA 紫外線照射処理による紙の物性値の変化

- 著者

- 金 鳳庸 磯貝 明 尾鍋 史彦 臼田 誠人

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.42, no.12, pp.1165-1170, 1988-12-01 (Released:2009-11-16)

- 参考文献数

- 14

No additive paper and four kinds of paper containing rosin-alum, alum only, alkylketenedimer (AKD) -cation polymer and cation polymer only were treated by UV light in air to study changes of paper properties, from the viewpoints of natural deterioration of paper.Photodegradation of cellulose and hemicellulose chains in paper brings about the slight increase in tensile strength and Young's modulus, and the drastic decrease in folding endurance for every paper examined so far. These findings may be explained by molecular rearrangements of degraded cellulose and hemicellulose to form new stable hydrogen bonds during irradiation. Sizing and retention chemicals have little influence on such paper properties even though some of them are chemically modified by UV irradiation.Since rosin-size has UV absorption at the relatively long wavelength region, UV treatments bring about the gradual loss of sizing effects and influence wet tensile strength and water absorption properties.Optical properties are primarily influenced by additives. Rosin-sized paper showed the darkest color after UV treatment because of its UV instability. AKD seems to suppress the coloring reactions to give lower discolored paper compared with paper without additive.

1 0 0 0 OA 高填料充填紙について

- 著者

- 小泉 正弘

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.42, no.11, pp.1022-1028, 1988-11-01 (Released:2009-11-16)

- 参考文献数

- 11

- 被引用文献数

- 1

1 0 0 0 OA 制御技術 / 理論の歴史と現在とこれから

- 著者

- 広井 和男

- 出版者

- JAPAN TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY

- 雑誌

- 紙パ技協誌 (ISSN:0022815X)

- 巻号頁・発行日

- vol.51, no.3, pp.514-527, 1997-03-01 (Released:2010-02-22)

- 参考文献数

- 14

Effectiveness of the plant control systems depends on the level of the control technologies built in the systems. In the twenty first century, more advanced control technologies will be indispensable in areas of safe and flexible plant operations, energy and resources saving, and environment maintenance.This paper reviews the history of control technologies and theories, the development and interaction of them, and presents the author's view on the current results and the future issues. In the sixty years since the introduction of PID control, various other control technologies and theories were tried but none has replaced PID nor taken the the lead in control. In the present age of digital control, the PID control is still in dominant use with more than 90% of all controls, and no immediate change is anticipated.From these facts, in order to achieve more advanced operation of plants, it will be necessary to further refine the PID control and apply non-PID control in more effective and Practical ways. I have pointed out that in the PID control, which is the basis of the control system, there are still unknown areas and those portions that need further refinements, and as an example of advanced PID control, explained the two-degree of freedom PID control. Since the characteristics of control object often vary considerably in the process control, the refinement of control can be said to be a fight against the change of characteristics of the control object. With these facts in mind, I have explained that, to further advance the plant control, many sided approaches are required including the refinement of classical control and the wide and practical applications of modern control, knowledge control, and other new control theories. In developing them, realization of control technologies that are both effective and user-friendly is strongly desired.