1 0 0 0 OA 積層造形技術—ラピッドプロトタイピングからラピッドマニュファクチャリングへ—

- 著者

- 新野 俊樹

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.76, no.12, pp.1340-1344, 2010-12-05 (Released:2011-06-05)

- 参考文献数

- 8

- 被引用文献数

- 6

1 0 0 0 OA 光学部品用金型加工向け超精密5軸加工機の開発

- 著者

- 廣瀬 智博 上 芳啓 清水 龍人 薮谷 誠 森本 喜隆

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.80, no.10, pp.944-949, 2014-10-05 (Released:2014-10-05)

- 参考文献数

- 20

- 被引用文献数

- 2 4

The machining of lens array mold for optics is attracting attention for fabricating camera lens modules. The profiles of axisymmetric aspheric lenses ranging from 1 to 5 mm in diameter are regularly arranged on lens array molds, allowing multiple optical lenses to be molded simultaneously. An ultra-precision machine tool for machining the lens array mold that has high-speed motion and high-accuracy positioning is needed. To solve this problem, we developed an ultra-precision 5-axis machine tool. In this paper, this machine tool was evaluated by high speed machining of the lens array mold. A surface roughness of within 2 nm and a form accuracy of within 0.1μm have been achieved using the shaper machining. The performance of the machine tool and the evaluation results for the machined mold are reported herein.

1 0 0 0 流動性火山灰を用いた浸炭焼入れ鋼の表面仕上げ法

- 著者

- 有吉 貴教 中西 勉 デン ガン

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集

- 巻号頁・発行日

- vol.2012, pp.335-336, 2012

本研究では,高強度歯車に用いられる浸炭焼入れ鋼を対象として,表面の凸部を滑らかにし,かつ,経済性と自然環境を考慮した加工法を開発する目的で,流動性火山灰を用いた表面仕上げ法を検討した.その結果,火山灰は,砥粒加工で用いられるシリカやアルミナを多く含むこと,火山灰は,鉱油に混ぜことで適切な流動性を持つこと,流動性火山灰を用いた表面仕上げ法は,浸炭焼入れ鋼の表面を簡便に滑らかにできることがわかった.

1 0 0 0 OA 名誉会員の紹介

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.77, no.6, pp.622-622, 2011-06-05 (Released:2011-12-05)

1 0 0 0 マイクロ旋盤の機械特性と加工品質の関係:ベッド剛性の影響

- 著者

- 山中 将 林 亮 伊藤 寿美夫 飯島 大典 井上 克己

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集

- 巻号頁・発行日

- vol.2005, pp.1243-1244, 2005

開発したA6(はがき)サイズのマイクロ旋盤では,ベッドに厚さ40 mmのむくの鋳物プレートを使用している.ベッド剛性が加工品質に及ぼす影響を調べるために,ベッド厚さを変えた場合の振動特性の評価と直径5 mmの真ちゅうを用いた切削試験を行った.粗さと真円度の測定結果と合わせて,結果について考察する.

1 0 0 0 タコの吸盤を模倣した真空吸着グリッパの開発

- 著者

- 高橋 智一 菊池 智史 鈴木 昌人 青柳 誠司

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.79, no.10, pp.970-971, 2013

- 被引用文献数

- 4

- 著者

- 勝又 大介 大野 学

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.79, no.9, pp.873-878, 2013

This paper describes development of an in-pipe mobile robot driven by pneumatic pressures. Town gas is supplied to houses through polyethylene pipes laid under the road. It are necessary to inspect these pipes regularly caused by the gas leak owing to earth load and oscillation for driving cars on the road. The robot is fabricated on the model of a green caterpillar for the purpose of inspecting these pipes. The caterpillar moves forward on leaf by waving motion of somites and clinging to a leaf for using abdominal legs and anal prolegs. The robot is structured by three somites and four suction brakes. This somite which structured by four pneumatic bellows actuators plays the role of the caterpillar's somite, and suction brake plays the role of the abdminal prolegs and anal prolegs. We confirmed that the robot's moving speed is 9.2 mm/s at acrylic pipe more 110 mm in inner diameter, and maximum traction force is 28.4 N. The robot having traction force 28.4 N can move mathematically in a horizontal pipe which has two elbows and 30 m length. In addition, mechanism of traction force is clarified by using the dynamic model of the robot.

1 0 0 0 OA サイクロイドボール減速機の基礎解析 (第1報)

- 著者

- 寺田 英嗣 牧野 洋 今瀬 憲司

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.54, no.11, pp.2101-2106, 1988-11-05 (Released:2009-10-08)

- 参考文献数

- 3

- 被引用文献数

- 1 12

A newly developed Cycloid Ball Reducer is introduced and analyzed. The fundamental element of the reducer consists of three components ; two surface-grooved discs and a train of balls. One of the discs has an epicycloidal-wave groove on one side of its surface, while the other disc has a hypocycloidal-wave groove. The two grooves face each other, and between them balls are arranged in a uniform angular pitch. The balls transmit torque between the two discs. A proper amount of thrust force is applied axially to eliminate backlash. This Cycloid Ball Reducer is suitable for application to servo mechanisms and robots. It is compact and easy to build in a unit, and has a large torque capacity. In this report, the principle of the reducer is analyzed using polar complex vectors. It is proved that the reducer has linear characteristics in principle. The reduction ratio can be chosen a wide range.

1 0 0 0 OA NCアセンブリセンタ

- 著者

- 牧野 洋

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.482, pp.250-255, 1975-03-05 (Released:2009-06-30)

- 参考文献数

- 3

- 被引用文献数

- 1

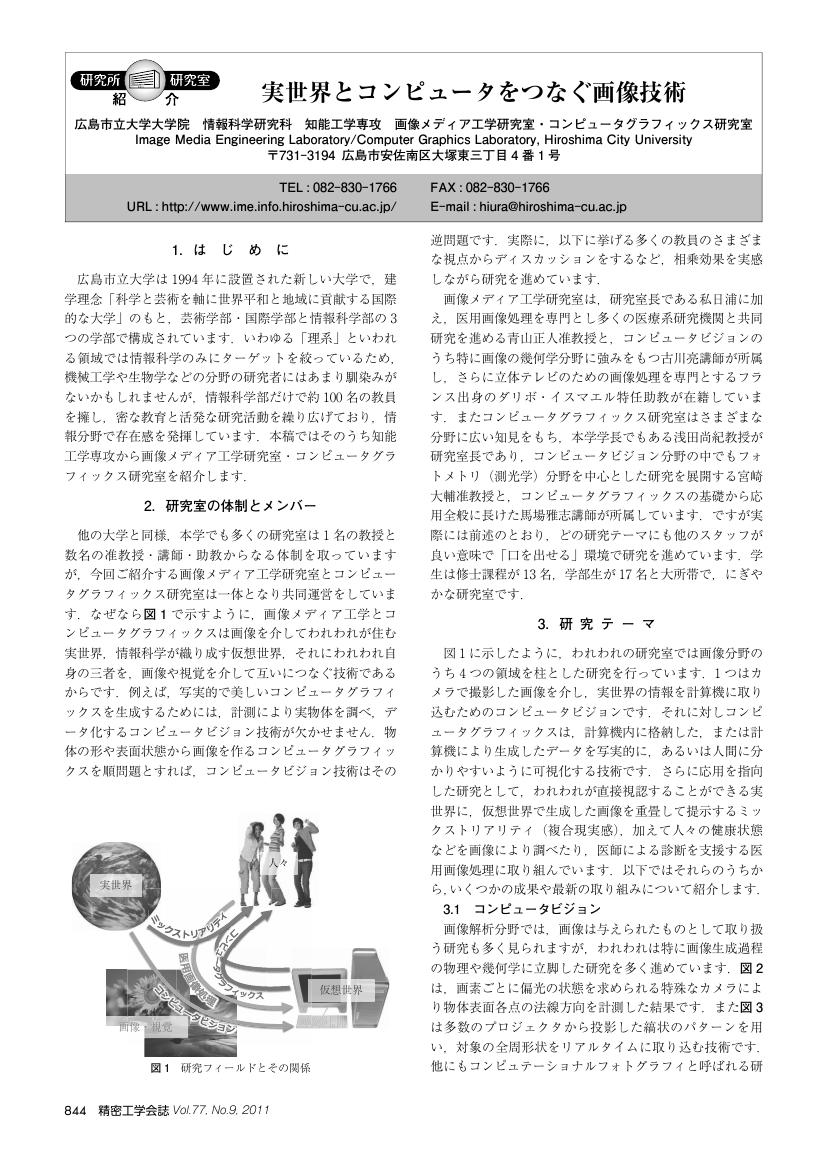

1 0 0 0 OA 実世界とコンピュータをつなぐ画像技術

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.77, no.9, pp.844-845, 2011-09-05 (Released:2012-03-05)

1 0 0 0 OA アルミニウム-珪素系合金の正面切削に関する研究

- 著者

- 財満 鎮雄 北村 利昭

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.36, no.428, pp.602-607, 1970-09-05 (Released:2009-07-23)

- 参考文献数

- 6

Facing tests with a sintered carbide have been conducted on three sorts of aluminium-silicon cast alloys, of which silicon contents are 13%, 17% and 23%, in order to investigate the feasibility of facing test which is frequently applied as a quick tool life test for ferrous materials. In addition to it, the other machinability characteristics of aluminium-silicon cast alloy are studied.The, tool life formula in facing, which was proposed by Brandsma on facing with a high speed steel tool, has been experimentally examined on 23% silicon aluminium alloy and has not been justified for this material. Thus, a new tool wear formula has been proposed for facing of aluminium alloys, and has been experimentally verified to agree fairly well. The tool wear is hardly recognized in facing 13% silicon aluminium alloy, whereas in the case of 17% and 23% silicon aluminium alloys recognizable wear occurs at higher cutting speeds, and, at the same time, the cutting force, especially, the traversing force, increases greatly. When the tool wear increases, the cutting temperature rise to nearly the recrystallization temperature of the work material.

1 0 0 0 OA ロボットの小形軽量化

- 著者

- 広瀬 茂男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.60, no.7, pp.914-919, 1994-07-05 (Released:2009-06-30)

- 参考文献数

- 13

1 0 0 0 OA 光磁気記録を応用したロータリエンコーダの試作

- 著者

- 飛田 和輝 大平 貴之 梶谷 誠 金森 哉吏 明 愛国

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.67, no.1, pp.96-100, 2001-01-05 (Released:2009-04-10)

- 参考文献数

- 9

- 被引用文献数

- 1 1

In this paper, a new kind of rotary encoder based on magneto-optical storage method is proposed. By using this method, a rotary encoder with small size, high accuracy and high response can be realized. MO encoder is more advantageous than a magnetic scale and optical encoder according to its high response and its high accuracy, respectively. High accuracy can be achieved by rerecording, therefore the error is corrected. Following issues are described: (1) A device for record, playback and evaluation of accuracy of MO encoder has been developed. (2) A necessary condition for record and playback for MO encoder was experimentally derived. (3) The MO encoder made for trial purposes was recorded by 2250 pulses per revolution directly from the referential encoder, as a result, accuracy of 2.5" and reproducibility of 0.079" were achieved.

1 0 0 0 OA 光磁気記録を応用したロータリエンコーダの試作(第2報)

- 著者

- 飛田 和輝 大平 貴之 梶谷 誠 金森 哉吏 明 愛国

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.67, no.12, pp.1976-1980, 2001-12-05 (Released:2009-04-10)

- 参考文献数

- 5

- 被引用文献数

- 1 1

The feasibility for fabricating a magneto-optical rotary encoder (MO encoder) has been shown in our previous paper. In this paper, an error corrected recording method to improve accuracy of the MO encoder is described. The recording method utilizes one feature of MO encoder, that is, ability for re-recording. First, an initial recording is made directly from referential encoder to MO encoder and angular errors of the MO encoder are measured. According to the errors, correcting values for canceling the errors are calculated based on Fourier components analysis. Finally, the MO encoder is re-recorded by the correcting values after erasing the initial recording. As the result of experiments, an accuracy of 1.3" for 2250 pulse/rev. and 1.7"for9000 pulse/rev. was achieved by using the error corrected recording method.

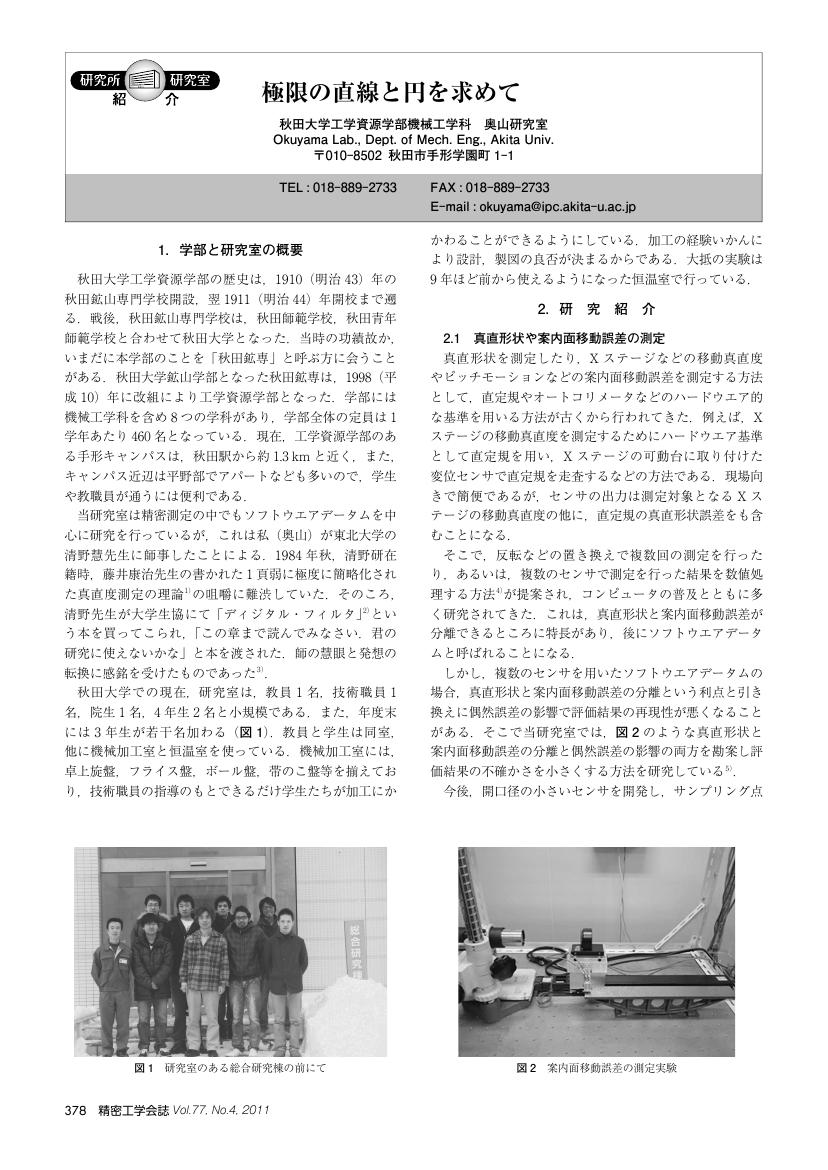

1 0 0 0 OA 極限の直線と円を求めて

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.77, no.4, pp.378-379, 2011-04-05 (Released:2011-10-05)

- 参考文献数

- 8

1 0 0 0 OA 第1回 成長と停滞の時代を生きて

- 著者

- 牧野 洋

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.71, no.9, pp.1103-1103, 2005-09-05 (Released:2009-04-10)

1 0 0 0 OA 第3回 成長と停滞の時代を生きて

- 著者

- 牧野 洋

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.71, no.11, pp.1362-1362, 2005-11-05 (Released:2009-04-10)

1 0 0 0 OA 直動形トロコイド歯車の基礎解析(第1報)

- 著者

- 寺田 英嗣 牧野 洋 今瀬 憲司

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.63, no.11, pp.1609-1613, 1997-11-05 (Released:2009-06-30)

- 参考文献数

- 6

- 被引用文献数

- 2

It is important to eliminate the backlash and to reduce inertia for high accuracy linear motion system. For this reason, the trochoid cam rack has been developed. The profile undercut must be avoided to satisfy the required performance. So this rack profile is ground using trochoid curve loci. In this report, the motion principle has been analyzed, and it becomes clear that there is the optimal value of rack profile offset factor which affects on pressure angle and radius of curvature. Also, roller diameter and tooth height affects on those characteristics. The optimal cam rack without profile undercut is designed using the selected each design factor. The prototype cam rack system using optimal design value is made and tested. It is proved that the system has high positioning accuracy without backlash.

1 0 0 0 OA 選択的コンプライアンス構造をもつ組立用ロボットの開発研究(第2報)

- 著者

- 古屋 信幸 相馬 勝男 陳 栄進 牧野 洋

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.49, no.7, pp.835-841, 1983-07-05 (Released:2009-07-23)

- 参考文献数

- 3

- 被引用文献数

- 2 8

The Selective Compliance Assembly Robot Arm (SCARA) is a newly developed robot for the use of small-lot batch assembly. In the previous report the characteristics of selective compliance effect were discussed and the experimental results on insertion were shown. The robot is controlled by an 8-bit microcomputer. In this report the hardware and the software of the controller are discussed. An arbitrary motion curve similar to a cam curve is used to move arms, and two axes are driven synchronously by the softwared DDA. Thus smooth movement is obtained. The results on repeating positioning accuracy, residual vibration and acceleration characteristics are shown. In spite of utilizing a low level microcomputer, the robot could obtain a sufficient speed up to 0.5 m/s which almost corresponds to the speed of a human operator.

1 0 0 0 OA 球面SCARAロボットの開発研究 (第2報)

- 著者

- 明 愛国 張 同庄 山本 唯司 古屋 信幸 村田 誠 牧野 洋

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.55, no.9, pp.1615-1620, 1989-09-05 (Released:2009-10-08)

- 参考文献数

- 5

The spherical SCARA robot is a newly developed robot for the operation on curved surface, especially on a sphere. In the previous report the basic concepts and characteristics are analysed. In this report the construction and specification of the prototype of the spherical SCARA robot are discussed. Then the hardware and software for controlling the prototype are considered. An arbitrary motion curve can be used to move arms and three axes are driven synchronously by the softwared DDA to obtain smooth movement. The methods to obtain large circle path and straight line path on the sphere are shown. It is possible to obtain any other paths by the method, as an example the stitching curve of the baseball is obtained.