- 著者

- 井上 雄吉 荒木 一富 西田 勇人 藤田 明美 藤本 万理 青山 麗子

- 出版者

- 一般社団法人 日本高次脳機能障害学会

- 雑誌

- 高次脳機能研究 (旧 失語症研究) (ISSN:13484818)

- 巻号頁・発行日

- vol.30, no.4, pp.496-509, 2010-12-31 (Released:2012-01-05)

- 参考文献数

- 41

- 被引用文献数

- 2

表出障害が主体の失語症に対する低頻度反復経頭蓋磁気刺激 (rTMS) の効果について検討した。対象は左大脳半球の主に慢性期脳血管障害 20 例 (梗塞 12 例,出血 8 例,全例右利き) で,発症から rTMS 開始までが 68~2793 日 (平均 591.6 日) であった。rTMS は健側右半球の Broca 野相同部位の Brodmann 45 野に,運動閾値の 90 %の強度で,1Hz,900 発刺激を計 10 セッション行った。評価は表出面を中心に,40 個の絵の呼称や短縮版 WAB,標準失語症検査 (SLTA) で行い,rTMS 前後の局所脳血流量 (rCBF) も調べた。結果は,絵の呼称では脳梗塞例全体で rTMS 施行 2 週後から有意の改善を認め,効果は終了 4 週後も持続し,SLTA でも有意の改善を認めた。脳出血例では有意の変化はなかった。脳梗塞例では rTMS 後に左基底核 rCBF の有意の増加を認めた。健側半球の低頻度 rTMS は,特に左基底核が保たれた慢性期脳梗塞に有効であり,失語症の改善に左基底核の関与が示唆された。

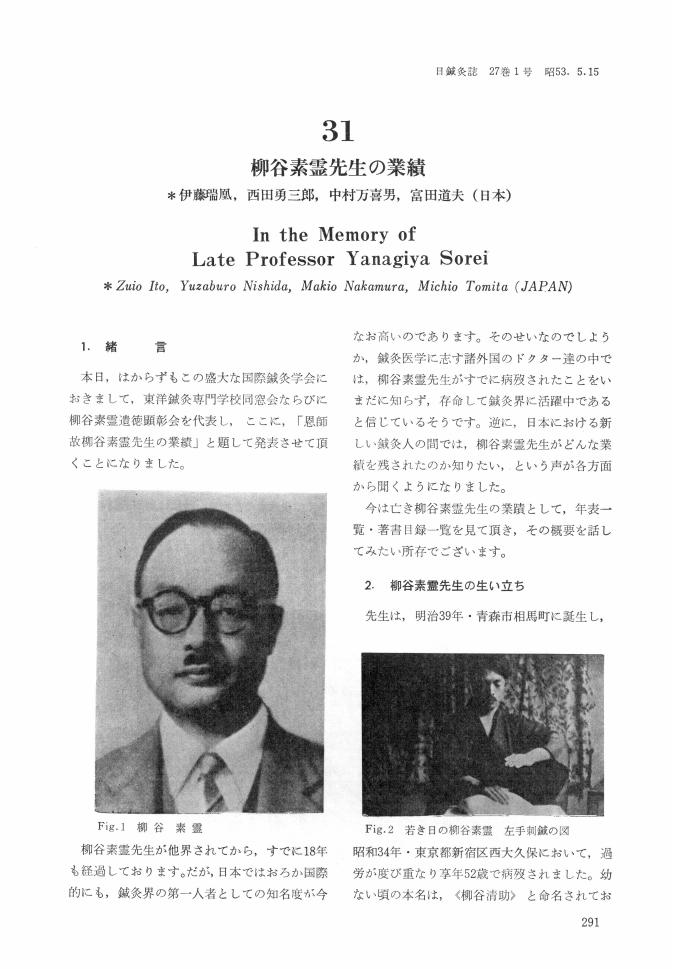

4 0 0 0 OA 柳谷素霊先生の業績

- 著者

- 伊藤 瑞凰 西田 勇三郎 中村 万喜男 富田 道夫

- 出版者

- 公益社団法人 全日本鍼灸学会

- 雑誌

- 日本鍼灸治療学会誌 (ISSN:05461367)

- 巻号頁・発行日

- vol.27, no.1, pp.291-298, 1978-09-30 (Released:2011-05-30)

- 参考文献数

- 70

3 0 0 0 OA 日本語版 Remote Associates Test は洞察を測定するか?

3 0 0 0 放射電力可変型21GHz帯放送衛星の電力分配法

- 著者

- 西田 勇人 中川 仁 正源 和義

- 出版者

- 一般社団法人電子情報通信学会

- 雑誌

- 電子情報通信学会技術研究報告. A・P, アンテナ・伝播

- 巻号頁・発行日

- vol.93, no.40, pp.5-10, 1993-05-21

- 被引用文献数

- 3

放射電力可変型21GHz帯全国放送衛星システムにおける電力分配量の制御法を検討した。この制御法は、日本各地で21GHz帯衛星電波を受信し、受信電波減衰量の短時間での変化に応じて電力を分配する方法であり、さらに全国約1300地点の1時間毎のアメダス降水量データを併用する。この方法の有効性を確認するために、全国6都市での12GHz帯のBS-2b電波の1分間毎測定値から計算した21GHz帯での減衰量と、アメダスを併用した電力分配シミュレーションを行った。その結果、所要C,Nを下回る時間率が、アメダスのみ使用した場合に比べ6都市平均で68%に減少し、回線維持率の向上が確認できた。また、シミュレーションにより本衛星システムの妥当性を確認した。

- 著者

- 大津 耕陽 西田 勇樹 木内 敬太 林 勇吾

- 出版者

- ヒューマンインタフェース学会

- 雑誌

- ヒューマンインタフェース学会論文誌 (ISSN:13447262)

- 巻号頁・発行日

- vol.24, no.4, pp.285-300, 2022-11-25 (Released:2022-11-25)

- 参考文献数

- 21

Although many chatbot applications have been proposed to support mental health care, the effective interaction design for chatbots to assist positive thinking for problem-solving without relying on the content of individual consultation is not clear. In this paper, we developed a chatbot application that can perform conversation tasks based on the Miracle Question, a method of the solution-focused approach. Then we validated that solution-focused interactive task on chatbot helps improve well-being index and active behavior. As a result, the results did not confirm that the proposed conversation task significantly improved the scores on each scale. However, when compared to existing tasks for behavior activation support, the proposed task tended to have a positive effect on improving well-being scores. Our finding has implications for the methodology and difficulties in supporting personal problem-solving based on minimal design.

2 0 0 0 OA 洞察問題としての日本語版Remote Associates Taskの作成

- 著者

- 織田 涼 服部 雅史 西田 勇樹

- 出版者

- 公益社団法人 日本心理学会

- 雑誌

- 心理学研究 (ISSN:00215236)

- 巻号頁・発行日

- pp.89.17201, (Released:2018-08-10)

- 参考文献数

- 23

- 被引用文献数

- 12

This paper proposes a new Japanese version of the Remote Associates Task (RAT). In a process of solving an insight problem, people often come to an impasse and end with an experience of surprise (“Aha!”) when they finally find their solution or are informed of the correct solution. We devised a set of 80 RAT problems that were intended to have the solver reach an impasse by evoking a certain fixed term. Two experiments showed that people have a stronger “Aha!” experience when they encounter the new RAT than the one proposed previously. The current paper provides a list of problems from the new RAT and basic data including the solution rate and the degree of the “Aha!” experience for each problem.

1 0 0 0 OA 洞察問題解決における無意識的過程に関する研究:プライミング法を用いた検討

1 0 0 0 柳谷素霊先生の業績

- 著者

- 伊藤 瑞凰 西田 勇三郎 中村 万喜男 富田 道夫

- 出版者

- 公益社団法人 全日本鍼灸学会

- 雑誌

- 日本鍼灸治療学会誌 (ISSN:05461367)

- 巻号頁・発行日

- vol.27, no.1, pp.291-298, 1978

- 著者

- 野口 晋 西田 勇 佐藤 隆太 白瀬 敬一

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.83, no.856, pp.17-00254-17-00254, 2017 (Released:2017-12-25)

- 参考文献数

- 14

- 被引用文献数

- 1

It is known that the cutting force excites the structural vibration of machine tool. In addition, cutting force acts on feed and spindle drive system as a force disturbance, and feed speed and spindle speed are changed. As the results, cutting force is also changed because the depth of cut and cutting speed are changed due to the machine vibration, feed and spindle speed changes. The purpose of this study is to analyze the coupled vibration between the machine tool behavior and the cutting force. In order to achieve the purpose, in this study, a coupled simulation method of the vibration of machine tool, the dynamic behaviors of feed and spindle drive systems and the cutting force is developed. Cutting force and machined surface geometry is simulated using the voxel simulator in which the workpieces is represented by voxels. Undeformed chip thickness can be calculated based on the relative position between the tool and workpieces, and the tool rotational angle at the each time step based on the voxel model. The cutting force is estimated based on the calculated undeformed chip thickness. The relative position between tool and workpiece at each time step is simulated by the feed drive system and machine tool structural models. The tool rotational angle is simulated by the spindle drive system model. The coupled simulation between the cutting force, structural vibration of machine tool and feed and spindle drive systems is carried out by applying the simulated cutting force and cutting torque as a disturbance to the feed and spindle drive systems and machine tool structure. Cutting tests and simulations are carried out with two kinds of radial depth of cut, 5 mm and 20 mm. It is confirmed that the machine tool dynamic behaviors due to the cutting force and torque which is also influenced by the machine tool behaviors can be simulated by the proposed method. It is also confirmed that the chatter vibration which is observed in case of the 20 mm depth of cut can be simulated by the proposed method.

1 0 0 0 OA 傾斜切削理論に基づくエンドミル加工の切削力モデル

- 著者

- 金子 和暉 西田 勇 佐藤 隆太 白瀬 敬一

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.83, no.856, pp.17-00247-17-00247, 2017 (Released:2017-12-25)

- 参考文献数

- 9

- 被引用文献数

- 3

In end milling, in order to improve machining efficiency and accuracy, instantaneous rigid force model is widely used to predict cutting force and improve cutting conditions. The instantaneous rigid force model is well known as the practically simple model to predict cutting force. However this model requires the six parameters called cutting coefficients which have to be determined by the experimental milling operation. So several experimental milling operations are needed before cutting force prediction. In this study, a new instantaneous rigid force model based on oblique cutting is proposed. In this force model, the end milling process is modeled using the oblique cutting model. Therefore, cutting force prediction can be realized using only the one parameter such as shear angle instead of the six parameters such as cutting coefficients required for a conventional instantaneous rigid force model. The shear angle can be determined from tangential milling force or milling torque. And this force model is easier to apply for practical cutting force prediction, because time and effort to determine the parameter(s) before cutting force prediction. The validation of this force model compared with the conventional force model is performed. As the result, cutting forces predicted by the proposed force model has good agreement with the measured cutting forces. Also, the proposed force model has good performance in a wide range of cutting conditions compared with the conventional force model.

1 0 0 0 OA 筋の疲労・回復予測のための筋疲労力学モデルの拡張(第1報 把持状態における検証)

- 著者

- 西田 勇 前田 正登 川野 常夫 白瀬 敬一

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.82, no.840, pp.16-00006-16-00006, 2016 (Released:2016-08-25)

- 参考文献数

- 11

- 被引用文献数

- 1

For several decades, factory automation or unmanned factory productivity has been progressed to realize much higher productivity in manufacturing. However, human centered manufacturing system is getting attention to realize much more flexibility for manufacturing of wide product variety and volume. So it is necessary to provide the safe and efficient environment to workers considering their own physical properties. This study investigated a mechanism of muscle fatigue and proposed a muscular fatigue model to evaluate muscle fatigue progress under several muscular force patterns. Previous studies have already proposed a muscular fatigue model. However, these previous studies discussed about the condition of maximum voluntary contraction. The new point of this study is considering several muscular force patterns including muscle recovery progress. This study proposed the method to estimate the endurance times for keeping constant forces considering the physical characteristics. This study also proposed the method to estimate the iteration numbers for keeping constant forces with interval. To validate the effectiveness of the proposed method, experimental verifications were conducted. The experimental results had a good agreement with the evaluation of muscle fatigue progress using the proposed method although it is necessary to consider the method to raise the precision of determining the physical parameters and the method to decrease the dispersion of experiments derived from the subjective judgement of participants. Success of resolving these issues will provide ergonomically safe and efficient working environments considering the physical properties of each worker.