1 0 0 0 OA 光リソグラフィの解像度の限界解像度を超えるナノインプリント技術開発

- 著者

- 井上 壮一 櫻井 淳平

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.86, no.4, pp.239-242, 2020-04-05 (Released:2020-04-05)

1 0 0 0 OA シンクロトロン放射光とX線リソグラフィ

- 著者

- 鳳 紘一郎

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.50, no.11, pp.1741-1746, 1984-11-05 (Released:2009-06-30)

- 参考文献数

- 14

1 0 0 0 OA 【画像応用技術専門委員会】ViEWとアルコン—IAIP最新活動報告—

- 著者

- 梅田 和昇 寺田 賢治 野口 稔

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.82, no.10, pp.841-845, 2016-10-05 (Released:2016-10-05)

- 参考文献数

- 4

- 被引用文献数

- 1

1 0 0 0 OA カーボンナノチューブとグラフェンの合成とその応用

- 著者

- 丸山 茂夫 千足 昇平

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.79, no.4, pp.297-300, 2013-04-05 (Released:2013-10-05)

- 参考文献数

- 12

1 0 0 0 OA パッチ分割切削法による任意三角形パッチ内への規則的表面模様形成

- 著者

- 福田 理明 笹原 弘之 松田 礼 堤 正臣

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.76, no.1, pp.111-115, 2010-01-05 (Released:2010-07-05)

- 参考文献数

- 7

- 被引用文献数

- 1 1

This study describes a new machining strategy to make regularly aligned geometric pattern by ball-end milling process employing a patch division milling technique. The surface is divided into a lot of triangle patch segments which is machined with helical tool path. It is newly proposed the way to array cutter marks straightly in arbitrary triangle patches. In addition, it is shown that the inclination angle of cutter marks array against the feed direction can be controlled by the appropriate setting of feed per tooth and cross feed for an arbitrary triangle patch. It is shown that the experimental results and simulation results are in good agreement. It is also reported that the well arranged cutter marks arrays are formed on the triangle patches on the spherical model.

1 0 0 0 OA びびり振動抑制のための不等リードエンドミルの検討

- 著者

- 高木 優次 木村 良彦

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2008年度精密工学会秋季大会

- 巻号頁・発行日

- pp.97-98, 2008 (Released:2009-03-01)

近年の高速・高能率加工や特に難削材の加工においては,びびり振動が発生しやすく,加工面性状の悪化が問題となっている。しかしながら,びびり振動を抑制するエンドミルは,いまだ十分に開発されているとは言えない。びびり振動に対して定評のある不等リード形状のエンドミルを使用したびびり振動の特性を評価し,不等リードエンドミルの開発を行った。

1 0 0 0 OA 商用人工現実感システム「RB2」

- 著者

- 菊池 望

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.57, no.8, pp.1347-1351, 1991-08-05 (Released:2009-10-08)

- 参考文献数

- 6

1 0 0 0 OA ナイフ状刃物による切断加工に関する研究 (第2報)

- 著者

- 金沢 憲一 中川 歩 三浦 崇

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.63, no.1, pp.70-75, 1997-01-05 (Released:2009-06-30)

- 参考文献数

- 2

- 被引用文献数

- 5 4

Mechanical properties of sweet potato are examined experimentally by compressive tests. And the computer simulation is conducted using FEM, on the separating process that sweet potato is cut by a knife-edged cutter with flat blade. The results obtained are as follows : (1) The calculation result almost corresponds to the process which sweet potato is separated by the preceding crack caused by a cutter except initiation. (2) The variety of cutting force is also the same as the experiment on each blade angle of a cutter. (3) In calculation, the effect of blade angle on two factors, the peak of cutting force and the cutting energy, is similar to the experiment. But both calculated values are higher than the experiment due to the high frictional coefficient between the separated surface and a cutter, which is obtained by a simple frictional test.

1 0 0 0 OA アフィリエイト通信

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.81, no.6, pp.520-522, 2015-06-05 (Released:2015-06-05)

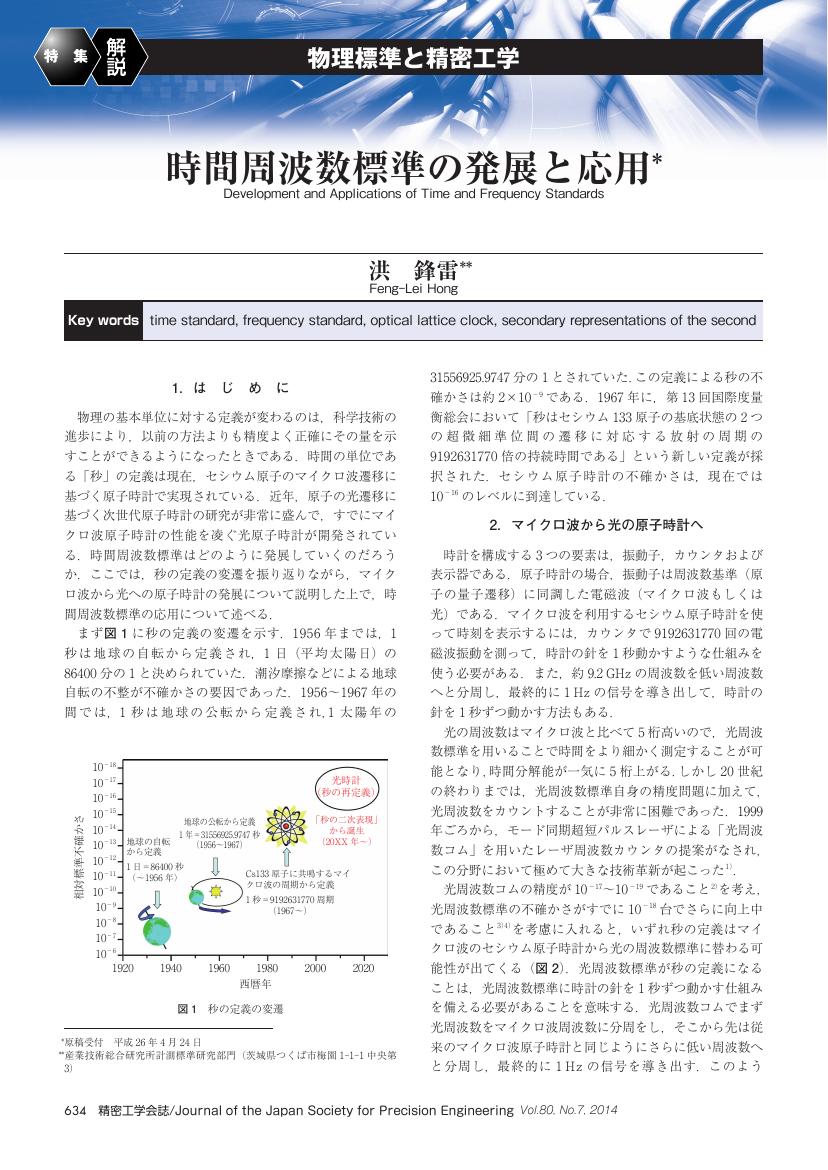

1 0 0 0 OA 時間周波数標準の発展と応用

- 著者

- 洪 鋒雷

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.80, no.7, pp.634-637, 2014-07-05 (Released:2014-07-05)

- 参考文献数

- 17

1 0 0 0 OA 高速M推定を用いたロバストな高速Hough変換

- 著者

- 沼田 宗敏 加藤 邦人 輿水 大和

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.76, no.5, pp.592-597, 2010-05-05 (Released:2010-11-05)

- 参考文献数

- 11

- 被引用文献数

- 2 2

This paper proposes a robust and fast Hough transform by which a set of lines can be detected by the use of high-speed M-estimator. This proposed method is one of the matching methods that is similar to the least squares (LS) method, however, the proposed method does not use the conventional parabolic function for the error function, and instead, does use the 2nd order B-spline basis function so that the following extreme advantages could be provided : The ill effect caused by the outlier will be drastically decreased in the proposed method, and in addition, the estimated line becomes just the same as those given by the LS fitting when no outlier exists. Furthermore it was possible to reduce the computation cost by introducing the successive usages of the rectangular filter.

1 0 0 0 OA 手書き図形の自動認識による3次元自由曲線モデルの生成

- 著者

- 古島 終作 金井 理 高橋 秀智

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.59, no.6, pp.969-974, 1993-06-05 (Released:2009-07-23)

- 参考文献数

- 9

- 被引用文献数

- 1

本研究の結論は以下のようにまとめられる.(1) 手書きの線画の位相情報と幾何情報をもとに, 1枚の線画中で左右対称な頂点と曲線の対応付けと, 2線画間で同一な頂点と曲線の対応付けを自動的に行う手法を提案した。(2) 2次元曲線と3次元曲線との透視変換の関係が明らかである有理Bézier曲線の性質を用いて, 左右対称又は2線画間で対応付けられた2次元曲線を表わす点列から, その点列と投影された曲線との距離が投影面上で最小になる3次元有理Bézier曲線を直接計算する手法を提案した.(3) (1), (2) の手法を統合し, 容易かっ高速に手書きの線画から3次元自由曲線モデルを生成できるシステムを開発し, 手法の有効性を確認した.なお, 本研究は東京工業大学工学部知能化機械研究設備を用いて行われた.

1 0 0 0 OA データ処理装置用入出力装置

- 著者

- 岩井 麟三

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.32, no.375, pp.247-256, 1966-04-05 (Released:2009-06-30)

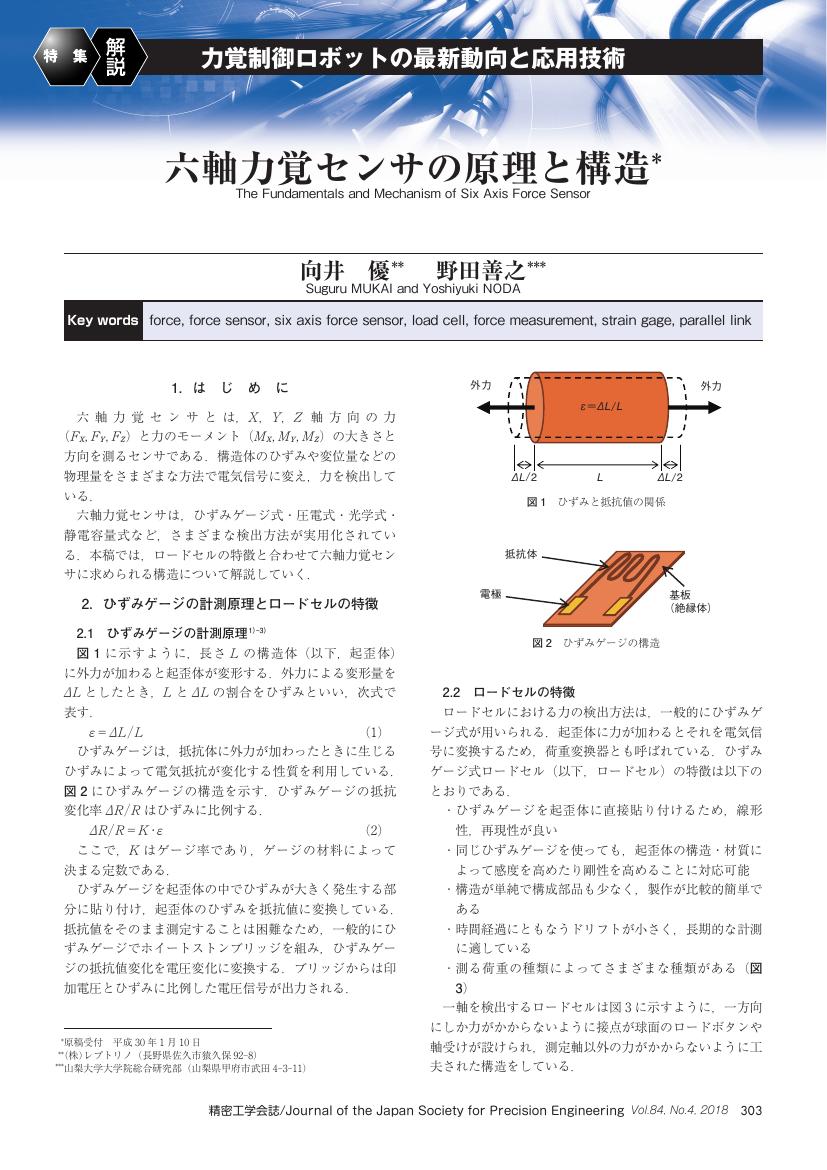

1 0 0 0 OA 六軸力覚センサの原理と構造

- 著者

- 向井 優 野田 善之

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.84, no.4, pp.303-306, 2018-04-05 (Released:2018-04-05)

- 参考文献数

- 3

- 被引用文献数

- 6

1 0 0 0 OA 静電容量型6軸力覚センサの開発・設計・製造

- 著者

- 佐伯 和司 西沖 暢久 鈴木 信人 岡田 和廣

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.84, no.4, pp.307-310, 2018-04-05 (Released:2018-04-05)

- 参考文献数

- 7

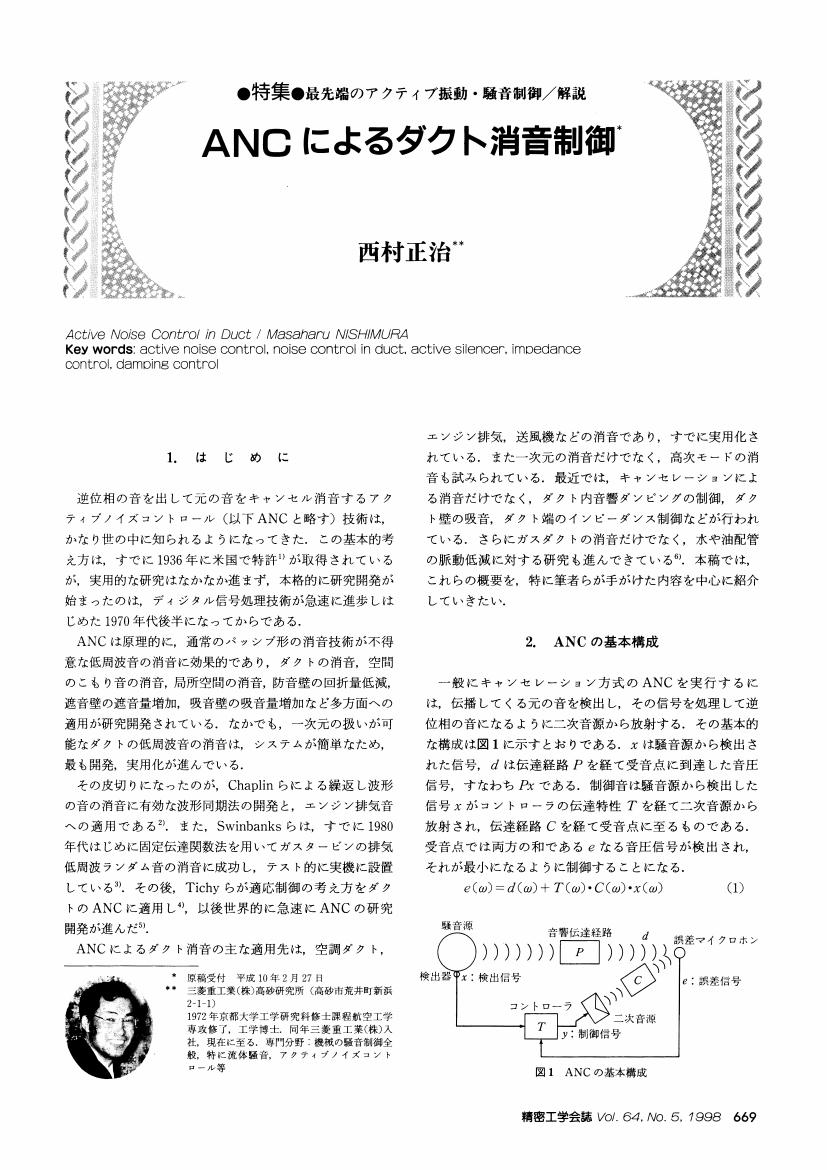

1 0 0 0 OA ANCによるダクト消音制御

- 著者

- 西村 正治

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.64, no.5, pp.669-673, 1998-05-05 (Released:2009-06-30)

- 参考文献数

- 13

1 0 0 0 OA イオン化蒸着法によるダイヤモンド及びcBN膜

- 著者

- 難波 義捷

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.53, no.10, pp.1523-1526, 1987 (Released:2009-06-30)

- 参考文献数

- 16

1 0 0 0 OA 複合工作機械によるミルターニング加工に関する研究

- 著者

- 村木 俊之 垣野 義昭 村上 大介

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.69, no.7, pp.965-969, 2003-07-05 (Released:2009-04-10)

- 参考文献数

- 4

- 被引用文献数

- 1 2

High speed dry turning is one of the most important themes in ecological manufacturing. But in conventional turning style, it is difficult to reduce cutting temperature because the cutting edge is contacted to the work-piece continuously. Then in mill-turning, high speed face milling is applied for machining of cylindrical parts, and it is possible to reduce cutting temperature by using high speed-interrupted-small depth cutting method so as high speed endmilling. In this study, we have made clear the ability of mill-turning, and optimum cutting conditions for tool life. So we developed the prototype cutters for mill-turning, and tested their performance

1 0 0 0 OA 製品設計と製造における「自由度」

- 著者

- 嶋田 憲司

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.80, no.2, pp.162-166, 2014-02-05 (Released:2014-02-05)

- 参考文献数

- 4

1 0 0 0 OA 銅およびアルミニウムの真空中の切削挙動

- 著者

- 上原 邦雄 檀原 袈裟男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.490, pp.1043-1049, 1975-11-05 (Released:2009-06-30)

- 参考文献数

- 9

This paper deals the cutting behavior of copper and aluminum in vacuum machining in which the materials were turned by specially made lathe at 40 m/min of cutting speed and under the reduction of pressure up to 10-4 mmHg. It was found that the cutting characteristics such as cutting force, cutting ratio etc. are not influenced by the degree of vacuum in machining tough pitch copper, oxygen free copper and 98% aluminum, however, they are affected in machining high purity aluminum. This is a contrasting result compared with the former paper in which the cutting behavior of carbon steel and titanium was examined. In order to clarify the cause of above phenomena, the experimental data were examined in detail basing on five factors which would affect the state of cutting in vacuum machining. As the result, it is cleared that the constancy of the cutting force in machining tough pitch copper and oxygen free copper is due to the nearly equal shear strength of adsorption layer or oxide film at the tool-chip interface compared with that of metallic contact part of the interface. Further, it is concluded that the cutting behavior of aluminum is affected strongly by the existence or the formation of γ alumina at tool-chip interface.