1 0 0 0 OA 位置決め機構の物理パラメータの一同定方法

- 著者

- 涌井 伸二

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.60, no.2, pp.211-214, 1994-02-05 (Released:2009-06-30)

- 参考文献数

- 4

- 被引用文献数

- 1 1

The positioning mechanism can be regarded as a simple vibration system with one degree of freedom. Generally speaking, it is difficult to identify the physical parameters of this mechanism without decomposing. In this paper, an identification method of physical parameters for positioning mechanism is described. Firstly it is shown that the viscous damping of slide mechanism can be derived by measuring the frequency response from the collocated sensor to the non-collocated sensor. Moreover, the spring constant between the mechanisms also can be derived more accurately in comparison with the value based on the impulse response. Secondary the equivalent viscous damping is calculated by means of the constant velocity test or the frequency response. Then the viscous damping of rotational mechanism may easily be derived by subtracting the converted viscous damping, which is the value of slide mechanism at the position of motor axis, from the equivalent viscous damping. Finally, the proposed identification method is applied to an actual positioning mechanism.

1 0 0 0 OA ダブルアングルドリルを用いた炭素繊維強化プラスチックの穴あけ加工

- 著者

- 田村 昌一 松村 隆

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2015年度精密工学会春季大会

- 巻号頁・発行日

- pp.247-248, 2015-03-01 (Released:2015-09-01)

炭素繊維強化プラスチックの穴あけ加工に対して,ドリル先端側の先端角が大きく,外周側の先端角が小さいダブルアングルドリルを適用し,その切削特性について議論する.一般的なドリルによる穴あけ試験も実施し,層間剥離に対する工具形状の効果について調べた.またエネルギ解析法による切削シミュレーションを用い,ダブルアングルドリルによる切削特性について解析し,ダブルアングルドリルの有効性について示す.

1 0 0 0 OA にじ面の研究

- 著者

- 藤本 定正 鮎沢 隆 巣山 博美

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.32, no.377, pp.409-413, 1966-06-05 (Released:2010-02-16)

- 参考文献数

- 1

- 被引用文献数

- 2

The angular distributions of reflected light from specular and indecent metal-surfaces finished by diamond cutting tools are measured by an automatic recording goniophotometer. The results are compared with the diffraction theory of optical gratings with triangular grooves with two flat faces, and the difference is discussed in connection with irregularity of the side faces of grooves on the surfaces.On both sides of the grooves on iridescent surfaces, there are many fine streaks parallel to the grooves which seem to be caused by unevenness of cutting edges of diamond tools. On other hand, the cutting edges of tools for specular surfaces are flat, and the distribution curves of reflected light correspond to the results calculated with diffraction theory fairly well.

- 著者

- 角田 馨 福田 栄治

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.26, no.309, pp.580-584, 1960

In most cases, the inner surface of the inner ring of the roller bearing or the inner surface of bushings is ground by the roll type centerless internal grinder.<BR>In this case, the work is held by 3 rolls and ground. Thus, the roll pressure imposed rdially on the work will restrict the vibration of work and, as well, will provide the work with axial thrust in the direction of the support. In auto-gaging, the gage pressure will work in the direction counter to the thrust and, if the work moves minutely in the direction of the axis, eventually working accuracy will be greatly affected adversely. As correlativity between the gage pressure and dimension accuracy exists, the correlativity between the roll pressure and thrust was sought for in order to establish the gage pressure.

1 0 0 0 OA 布機械特性簡易計測に基づく着装シミュレーションの基礎研究

- 著者

- 赤塚 由菜 青山 英樹

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2018年度精密工学会秋季大会

- 巻号頁・発行日

- pp.14-15, 2018-08-20 (Released:2019-02-20)

アパレル製品設計工程におけるデザイナの負担を軽減するため,布の機械特性を反映したよりリアルな着装シミュレーションが求められている.本研究では布機械特性簡易計測法,着装シミュレーションシステムを提案する.布の異方向性を考慮した引張特性,せん断特性,曲げ特性を簡易的な装置で計測し,モデルパラメータとしてシミュレーションに入力する.物体への着装を想定したシミュレーションを行い,その形状を評価する.

- 著者

- 菊地 千之 臼井 英治 星 光一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.30, no.351, pp.316-324, 1964

Based upon the slip line theory applied to machining with cut-away tools proposed in the previous papers, the cutting force equilibrium through the plastic field is analyzed.<BR>Cutting forces and chip formation in machining with various types of cut-away tool are compared with the conventional tool. Tools having restricted double rake face are discussed in view of cutting forces, chip formation and slip line construction of the plastic field produced.

- 著者

- 星 光一 臼井 英治

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.34, no.397, pp.113-120, 1968

- 被引用文献数

- 1

Wear characteristics and tool-life curves in machining of low and medium carbon steels with various types of cut-away tools made of carbide and high speed steel are described and compared with those for conventional tools.<BR>Although an artificial reduction of natural tool-chip contact length usually reduces both crater and flank wear, there always exists optimum value of contact length below which tool-life is shortened. The optimum length depends on side rake angle of the tool and is found that the smaller the rake angle, the shorter the length becomes.<BR>In comparison of tool wear at the optimum contact length, it is found that flank wear is somewhat increased, but crater is substantially reduced as the rake angle is decreased.<BR>Tools with sufficiently reduced contact length show a special type of crater which is not formed on the first rake face, but mainly develops along the second rake face. This characteristic is well explained by the theory of cutting mechanism presented in the previous papers.<BR>Not only cutting temperature but also shape of cutting edge has a great importance on tool wear even in high speed machining. The wear mechanism appears to be explained as a stressdependent rate process.

- 著者

- 岸浪 建史 秋山 俊彦 星 光一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.37, no.441, pp.701-707, 1971

- 被引用文献数

- 1

This paper describes the effects of the artificially controlled shear angle on the metal cutting process. From the experiments in which commercially pure lead is cut with various controlled shear angles, constant cutting speed, and depth, and various rake angles, the following results were obtained.<BR>(1) Taking rake angle (α) as parameter and increasing the controlled shear angle (φ), the points (φ, β-α) move along a right convex curve on the φ vs β-α plane on which critical points giving a minimum value of cutting force (<I>F<SUB>c</SUB></I>, min), lie in the vicinity of Merchant's Line.<BR>(2) The variation of φ does not influence the friction force on the rake face (CF), and the angle which gives a minimum cutting force (<I>F<SUB>c</SUB></I> min) gives a maximum value of coefficient of friction on the rake face.<BR>(3) Hydrostatic pressure on the shear plane increases with the increase of φ, and does not influence the shear stress on it.<BR>(4) It has been confirmed either the shear plane model does not agree with the cutting mechanics for low cutting speed or the angle φ is such that the total cutting power is not minimum.

- 著者

- 嘉数 侑昇 沖野 教郎 星 光一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.38, no.448, pp.436-442, 1972

Due to the increasing popularity of Numerical Controlled Machine Tool Systems, the development of the higher level soft wares in this field becomes necessary. Further more, direct connection between Computer-Aided Design (CAD) and Computer-Aided Manufacturing brings about a problem.<BR>In order to cope with these situations, this paper proposes a new method on the automatic programming for NC considering the connection of both systems.<BR>After description of the workpiece profile by “Formulated Pattern” in the process of CAD, this method makes it possible to generate automatically NC commands for the tool path.<BR>The basic idea of this method is to establish the penalty surface arround the workpiece profile as a guide for determining the tool path.<BR>Since, using “Formulated Pattern”, the penalty can be given such as having minimum value on the cutting point, the problem for finding tool path is reduced to that for seeking minimum on the penalty surface.<BR>In this paper a theoretical development of this principle and practical algorithm for the determination of tool path are described with two examples, NC milling of NASA Airfoil pat-tern and plate cam designed by CAD procedure. Then, a method for collision check using same principle is described too.

- 著者

- 臼井 英治 星 光一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.30, no.350, pp.273-284, 1964

- 被引用文献数

- 4

In the previous papers, it was reported that the plastic flow ahead of the restricted tool-chip contact length of cut-away tools is produced through a slip-line field which involves a centered fan.<BR>The plastic flow peculiar to the tools bears a great resemblance to the curved layer structure of built-up edge and the plastic flow within the chip ahead of the built-up edge nose, which are usually observed on etched specimen under microscope. In addition, the plastic flow itself turns to the stable built-up edge under some conditions.<BR>This paper stresses the importance of the plastic flow due to the centered fan of slip lines for more rational understandings of the nature of built-up edge. In this connection, the formation and the growth of the natural built-up edge as well as the built-up edge produced by cut-away tools are critically re-examined.

1 0 0 0 世界で戦う石川佳純選手が語る"ものづくり"への期待

- 著者

- 長藤 圭介 近藤 誠一 篠﨑 烈 根本 賢太郎

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.85, no.1, pp.3-6, 2019

1 0 0 0 OA ハチの巣作りロボットの研究

- 著者

- 本間 章彦

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.62, no.6, pp.805-809, 1996-06-05 (Released:2009-06-30)

- 参考文献数

- 7

- 被引用文献数

- 1 1

The present paper deals with possible construction methods of three-dimensional shapes based on the nesting behavior of paper wasps. Paper wasps can construct combs of hexagonal cells with a regular arrangement. This paper describes observation and analysis of such nesting behavior. Observation results show that characteristic movements of antennae and nesting behavior, so called “taxis”, are used in determining how to shape the nest. Construction experiments are conducted to ascertain the relationship between constructed shapes and construction algorithms based on the nesting behavior. The results are as follows : 1. Using base shapes as a guide mark, construction algorithms of threedimensional objects based on the movements of sensors and simple moving rules lead to the construction of similar shapes and different shapes. 2. The movements of antennae and behavior, so called “taxis”, are used in determining how to shape the nest.

1 0 0 0 OA レーザ干渉法を利用し角縦弾性係数の測定

- 著者

- 今井 秀孝 飯塚 幸三

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.52, no.4, pp.643-648, 1986-04-05 (Released:2009-06-30)

- 参考文献数

- 10

An apparatus for the measurement of Young's modulus and its thermal coefficient has been newly developed. Both the tension and bending methods are available in this apparatus. The elongation in the tensile test or the deflection in the three-point bending test is detected by using a specially designed sample holder together with a He-Ne laser interferometer with an accuracy of better than 0.1 μm. This apparatus is especially suitable for such thin specimens as leaf springs and hair springs which are often used in precision machines or measuring instruments. The minimum size of specimen to be measured is 0.1 mm in diameter or 5 μm in thickness. Young's modulus of ordinal materials can be measured with an accuracy of better than ±3% in 95% confidence interval. Young's moduli measured by the tension method and bending method were compared with each other and the result showed a good agreement. Thermal coefficients of Young's modulus of six kinds of spring materials were also measured by means of the bending method in the temperature range between 0°C and 50°C.

1 0 0 0 OA 固体材料のフレクソエレクトリック効果とその応用の可能性について

- 著者

- 辺見 信彦

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2019年度精密工学会秋季大会

- 巻号頁・発行日

- pp.336-337, 2019-08-20 (Released:2020-02-20)

フレクソエレクトリック効果はひずみの空間的な変化(ひずみ勾配)により電気分極が発生する現象である。圧電効果よりも分極量は小さいと言われてきたが,比較的大きなフレクソエレクトリック分極が得られる可能性が近年明らかになっている。著者はPZTのフレクソエレクトリック効果について調査しており,最近の世界での研究の動向を紹介するとともに,実際に実験により得られた結果や今後の応用の可能性について報告する。

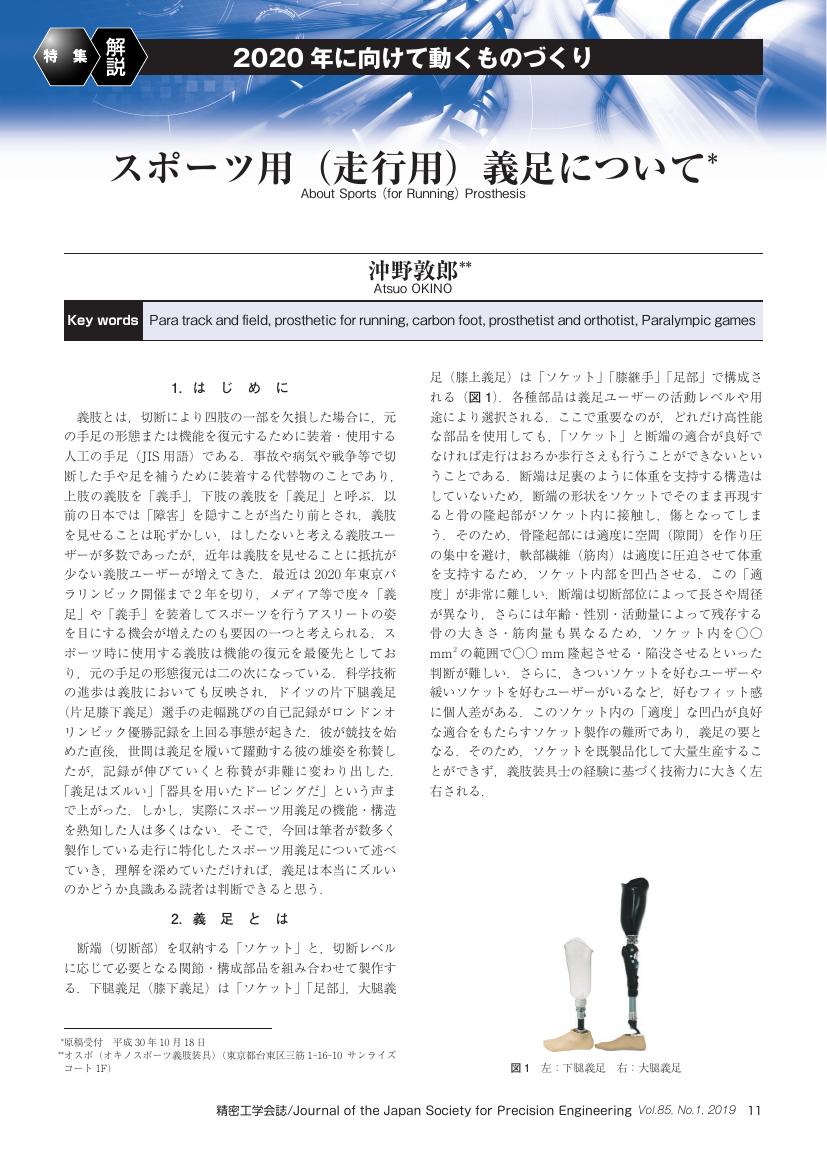

1 0 0 0 OA スポーツ用(走行用)義足について

- 著者

- 沖野 敦郎

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会誌 (ISSN:09120289)

- 巻号頁・発行日

- vol.85, no.1, pp.11-14, 2019-01-05 (Released:2019-01-05)

- 参考文献数

- 1

- 被引用文献数

- 1

- 著者

- 飯野 大輝

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集

- 巻号頁・発行日

- vol.2020, pp.379-380, 2020

<p>三次元フラッシュメモリは人類の生成する膨大な情報を記憶するデバイスとして大きな役割を果たしている。ドライエッチングプロセスは、三次元フラッシュメモリの製造におけるキープロセスであり、様々な技術分野でのイノベーションが求められる。本報告では、ドライエッチングプロセス開発の概要を述べるとともに、具体例として、On-site合成したC<sub>2</sub>F<sub>4</sub>ガスを適用したエッチングプロセスについても紹介する。</p>

1 0 0 0 OA 連続的な環境音の認識に関する研究 水流音のスペクトログラムの統計的な特徴量

- 著者

- 大久保 翔太 正田 純 ゴン 志豪 佐々木 健

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2017年度精密工学会春季大会

- 巻号頁・発行日

- pp.549-550, 2017-03-01 (Released:2017-09-01)

非音声である環境音の認識技術はセキュリティシステムやビデオのシーン解析などにおいて需要が高まっている.本研究では認識対象として定常的に流れる水の音を選び,スペクトログラムに現れるパワーの大きい領域を抽出し, その出現頻度と分布を音の特徴量として分析した.その結果、スペクトルの強い領域の周波数帯、間隔において他の音との差異がみつかった.

- 著者

- 田中 義信 井川 直哉

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.26, no.302, pp.149-154, 1960

The authors have made investigations about diamond wheel grinding in which plunge cut method by plain cup diamond wheels of bronze bonded was adopted. In this paper the influences of the diamond concentration of the wheel on stock removal is discussed theoretically and experimentally. And surface roughness produced in the grinding tests is also described.<BR>Theoretical investigation shows the tendency that stock removal decreases with the increase of the diamond concentration of the wheel if assumed the wheel having the abrasive grains whose tip has spherical shape, and the similar tendency was recognized in the grinding tests to some extent.<BR>Characteristics of the stock removal-normal grinding force (or contact pressure between the wheel and work surface) for a diamond wheel was clarified.<BR>It is also known that surface roughness <I>H</I><SUB>max</SUB> decreases with the increase of the diamond concentration of the wheel.

1 0 0 0 加速電圧変調電子ビーム露光による三次元生体模倣構造の作製

- 著者

- 後藤 晃平 谷口 淳

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集

- 巻号頁・発行日

- vol.2018, pp.851-852, 2018

<p>先行研究では電子ビームリソグラフィにおいて、加速電圧により加工深さを制御することができることを明らかにした。そこで本研究ではこの加速電圧変調法を用いて機能性を持った三次元の生体模倣構造の作製に着手した。その結果、流体抵抗を軽減する鮫肌や撥水性と吸着性を合わせ持つばらの花表面の模倣構造の作製に成功した。本研究より、この加速電圧変調法を用いてより複雑で微細な三次元構造の作製が可能であると考えられる。</p>

1 0 0 0 OA 日本刀(キーノートスピーチ) 世界に冠たる鉄の芸術

- 著者

- 石川 憲一

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密工学会学術講演会講演論文集 2011年度精密工学会秋季大会

- 巻号頁・発行日

- pp.19-20, 2011 (Released:2012-03-05)

日本刀は、本来、武器であることから実用性が要求されてきたが、日本人の美意識を反映して更に美的要素が追求され、刀匠達は日本刀を鎌倉期に完成させた。そして、五カ伝を中心とする作刀が行われ、歴史を貫くハイテクノロジーとしての日本刀は、世界に冠たる鉄の芸術品として昇華している。本稿では、日本刀の歴史を簡単に通観し、作刀法や現代の修業制度を紹介すると共に、研磨工程や鑑賞の要点などについて述べる。