- 著者

- 谷村 篤 岡 信和 川口 創 西川 淳 高橋 邦夫 真壁 竜介 Hosie Graham 小達 恒夫 Atsushi Tanimura Nobukazu Oka So Kawaguchi Jun Nishikawa Kunio T. Takahashi Ryusuke Makabe Graham Hosie Tsuneo Odate

- 雑誌

- 南極資料 = Antarctic Record (ISSN:00857289)

- 巻号頁・発行日

- vol.52, no.1, pp.1-8, 2008-03

2002年及び2003年の南極海の夏季,東部インド洋区のウイルクスランド沖の東経140度線上において,白鳳丸及びタンガロアによる3回の調査航海によって行われたRMT-8(目合: 4.5mm, 開口面積: 8m3)ネット採集によって得られた標本に基づいて,大型動物プランクトン群集構造を調べた.クラスター解析の結果,大型動物プランクトン群集は,南極周極流の南縁(SB-ACC: Southern Boundary of the Antarctic Circumpolar Current)で大きく二つの群集に分けられた.すなわち,SB-ACCの北方では大型動物プランクトン群集は,Salpa thompsoni, Euphausia frigida及びThemisto gaudichaudiiなどのoceanic communityが卓越していた.一方,SB-ACCの南方ではEuphausia superba及びEuphausia crystallorophiasなど大陸寄りに主分布域をもつ動物プランクトンが卓越していた.SB-ACCは,南極海の上記の主要な大型動物プランクトン種の出現の差によって特徴付けられることが示唆された.

1 0 0 0 慢性腎不全患者の指示量に対する充足率について

1 0 0 0 OA 成績下位の学習者の全体的協働経験による能動的な関わり合いの持続性が媒介する成績向上

- 著者

- 林 康成 島田 英昭 三崎 隆 西川 純

- 出版者

- 一般社団法人 日本理科教育学会

- 雑誌

- 理科教育学研究 (ISSN:13452614)

- 巻号頁・発行日

- vol.62, no.2, pp.537-545, 2021-11-30 (Released:2021-11-30)

- 参考文献数

- 21

本研究は,小学校理科において成績下位層の学習者が全体的協働の授業を経験したこと(以下,全体的協働経験とする)による能動的な関わり合いと成績向上の持続性を明らかにすることを目的とした。各30人の学習者からなる第4学年の2クラスで,全体的協働授業を経験したクラスと小規模協働授業を経験し全体的協働授業を経験しなかったクラスを設定し,協働授業経験の1ヶ月後,同一教諭が両クラスに小規模協働授業を実施した。事前・事後テストの得点,授業中の立ち歩き回数,会話内容と回数を分析した結果,全体的協働を経験をした成績下位層の学習者は,全体的協働を経験していない成績下位層の学習者よりテスト得点が上昇し,授業中の立ち歩き回数が多く成績向上に有効な会話が多く現れることが明らかになった。さらに,会話内容の質的な分析と事後インタビューの分析を行った。これらの結果から,全体的協働経験による能動的な関わり合いが持続し,成績が向上することが示唆された。

1 0 0 0 不確実性を考慮した都心部商業地区の回遊行動のモデル化

- 著者

- 湯沢 昭 須田 熈 西川 向一

- 出版者

- 公益社団法人 土木学会

- 雑誌

- 土木学会論文集 (ISSN:02897806)

- 巻号頁・発行日

- vol.1993, no.458, pp.73-80, 1993

- 被引用文献数

- 1

本研究は, 消費者の都心部商業地区における買物・娯楽行動に焦点をあて, 商業地区の選択問題と回遊行動に関する分析を中心に行うものであり, 大きく2つの内容から構成されている. 1つは, 認識の不確実性を考慮した意思決定モデルの作成であり, 2つ目は非定常確率モデルによる回遊行動の分析である. これは商業地区の整備が, 当地区への直接の来街頻度の増加と回遊による増分を同時に評価する上で不可欠なものである. 本研究で提案した商業地区評価手法を, 観測データを用いて検証したところ, その有効性が確認された.

1 0 0 0 OA 魚類から排出されたアンモニアの観賞魚用アンモニア測定キットによる検出方法の確立と授業実践

- 著者

- 西川 洋史

- 出版者

- 一般社団法人 日本生物教育学会

- 雑誌

- 生物教育 (ISSN:0287119X)

- 巻号頁・発行日

- vol.60, no.3, pp.110-116, 2019 (Released:2019-12-16)

- 参考文献数

- 11

- 被引用文献数

- 1

現在,生物の代謝産物を扱った生徒実験は呼気に含まれる二酸化炭素の検出など限られているが,魚類を小ケースで飼育すると比較的高いレベルのアンモニアが蓄積することが知られる.そこで市販の簡易検査キットを用いて魚類から排出されるアンモニア量を測定した.具体的には観賞魚として人気のあるキンギョCarassius auratus auratus,ミナミメダカOryzais latipes,エンゼルフィッシュPterophyllum scalare var.,コリドラスCoridoras aeneusを250 mlの飼育水に入れ,排出されたアンモニア濃度区分を求めた.その結果,キンギョ20個体またはコリドラス6個体を10分間室温で飼育したところ,数回の実験すべてにおいてのアンモニア濃度区分が1.5 mg/L以上に達した.これをもとに授業実践ではキンギョ10~20個体をビーカーに10分間入れて,排出されたアンモニア量を測定した.この一連の過程は50分間の授業内に終わり,かつすべての生徒が優位なアンモニア上昇を確認することができた.これまで水中のアンモニア検査キットは環境の観点から使われてきたが,本実験・教育実践では生理機能の観点から扱った.この展開は,生物代謝成分を直接扱って生物の主要構成元素の理解につなげていく教育実験系が網羅されたことを意味する.

1 0 0 0 野菜トラップによるスクミリンゴガイの捕獲効率の向上

- 著者

- 国本 桂範 西川 学

- 出版者

- 日本農作業学会

- 雑誌

- 農作業研究 (ISSN:03891763)

- 巻号頁・発行日

- vol.43, no.2, pp.75-82, 2008-06-25

- 参考文献数

- 11

スクミリンゴガイの水田に入っての拾い取りによる捕獲と,水田内に設置した野菜トラップによる捕獲および水田周囲に設置した野菜トラップによる捕獲について,作業時間,捕獲効率を比較した.貝が少なかった水田を除き,拾い取りによる捕獲の作業時間は,10a当たり2時間以上を要し,最も捕獲量の多かった水田では約536分を要した.しかし,1回の拾い取りでの捕獲効率は全捕獲の68.3%に止まり,稚苗移植水稲での要防除水準まで貝密度を減少させるには複数回の拾い取りが必要であった.これに対し,水田内に設置した野菜トラップでは4回のトラップでの捕獲を行うことで要防除水準以下の密度まで貝を減少させることができ,10a当たりの作業時間は約418分だった.水田周囲に設置した野菜トラップでは小規模な水田では13回のトラップによる捕獲で,要防除水準以下の密度にまで貝を減少させることができた.10a当たりに換算した作業時間は約116分で,この方法により短時間で簡単に貝を捕獲できることが示唆された.

1 0 0 0 OA エントリーシートを用いた機械学習による採用企業推定

- 著者

- 西川 浩平 松村 敦 宇陀 則彦

- 雑誌

- 第82回全国大会講演論文集

- 巻号頁・発行日

- vol.2020, no.1, pp.405-406, 2020-02-20

新卒の就職活動では,就職活動生が企業にエントリーシート(以下,ES)を提出し,企業がそのESを元に採用を判断するという過程が一般的となっている.ESには,志望動機や自己PRなどを書くよう求められており,企業に 採用された就職活動生のESを分析することで,各企業がどのようなパーソナリティを持った人材を求めているかを推定することが可能である.そこで本研究では,テキストデータであるESに対して機械学習を用いることで,どの企業に提出されたESであるかの推定を行った.本発表では,その推定結果と分析結果を報告する.

- 著者

- 西川 康男

- 出版者

- ARMA International東京支部

- 雑誌

- Records & information management journal = レコード&インフォメーションマネジメントジャーナル : the information management professionals

- 巻号頁・発行日

- no.48, pp.28-32, 2021-09

- 著者

- 西川 康男

- 出版者

- ARMA International東京支部

- 雑誌

- Records & information management journal = レコード&インフォメーションマネジメントジャーナル : the information management professionals

- 巻号頁・発行日

- no.48, pp.1-4, 2021-09

1 0 0 0 認知モデルを用いたインタラクティブな音韻意識推定法の検討

- 著者

- 西川 純平 森田 純哉

- 出版者

- 一般社団法人 人工知能学会

- 雑誌

- 人工知能学会研究会資料 先進的学習科学と工学研究会 93回 (2021/11) (ISSN:13494104)

- 巻号頁・発行日

- pp.38-43, 2021-11-15 (Released:2021-11-15)

言語発達の過程で個々の子どもが抱える困難は多様である.とくに音声の認識を支える音韻意識という能力が未熟なとき様々な発話の誤りが表れる.個別の誤りへの対応では,それぞれのメカニズムの理解に基づく支援が重要である.このために,子ども個人の音韻意識に対応づけた認知モデルを利用する音韻意識形成支援システムの構築を目指す.とくに本研究では,子どもがもつ音韻意識の状態を推定する方法を検討する.

- 著者

- 西川 星也 高松 敦子

- 出版者

- 金原一郎記念医学医療振興財団

- 巻号頁・発行日

- pp.155-158, 2016-04-15

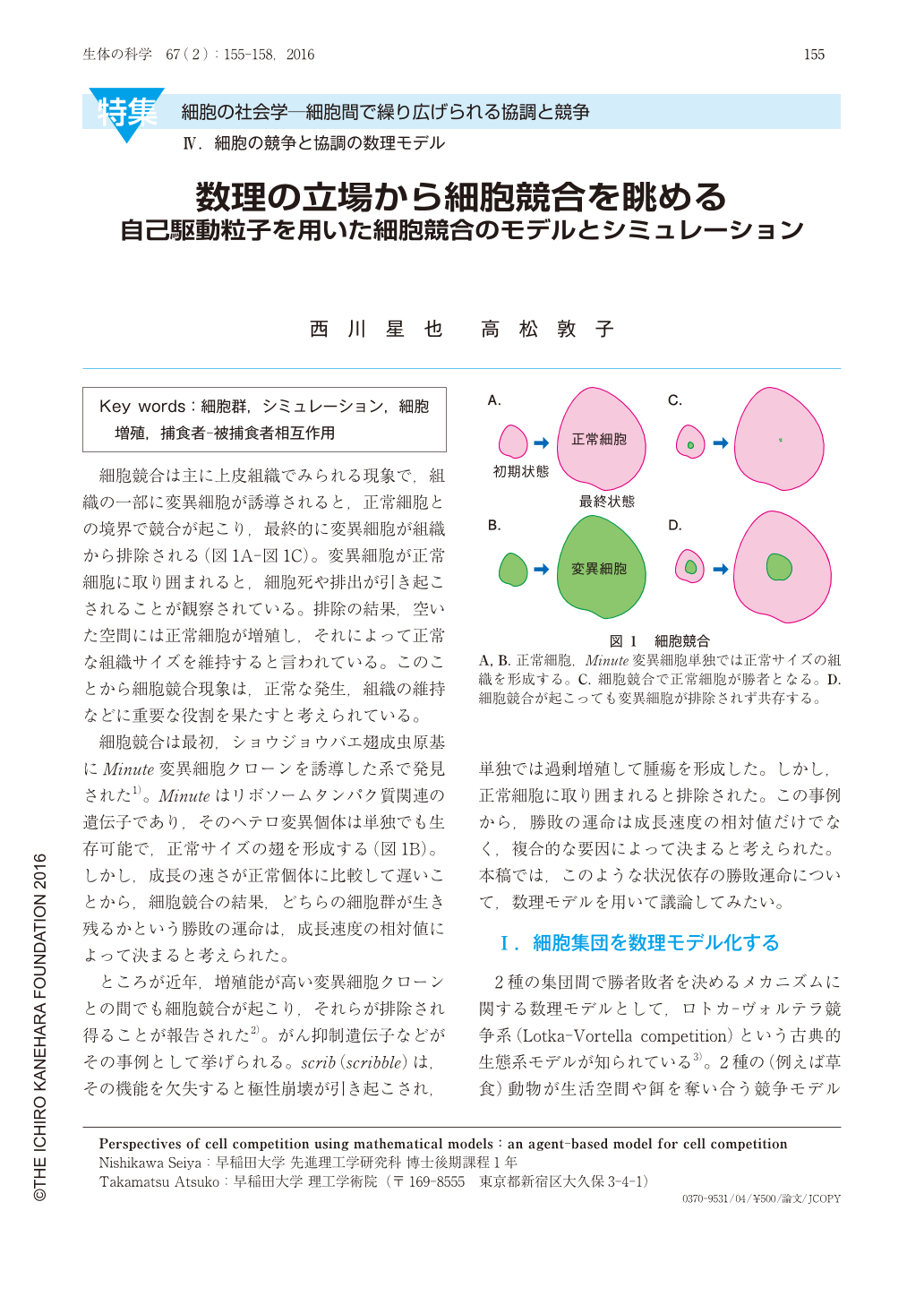

細胞競合は主に上皮組織でみられる現象で,組織の一部に変異細胞が誘導されると,正常細胞との境界で競合が起こり,最終的に変異細胞が組織から排除される(図1A-図1C)。変異細胞が正常細胞に取り囲まれると,細胞死や排出が引き起こされることが観察されている。排除の結果,空いた空間には正常細胞が増殖し,それによって正常な組織サイズを維持すると言われている。このことから細胞競合現象は,正常な発生,組織の維持などに重要な役割を果たすと考えられている。 細胞競合は最初,ショウジョウバエ翅成虫原基にMinute変異細胞クローンを誘導した系で発見された1)。Minuteはリボソームタンパク質関連の遺伝子であり,そのヘテロ変異個体は単独でも生存可能で,正常サイズの翅を形成する(図1B)。しかし,成長の速さが正常個体に比較して遅いことから,細胞競合の結果,どちらの細胞群が生き残るかという勝敗の運命は,成長速度の相対値によって決まると考えられた。

- 著者

- 西川 智 福島 誠一郎 矢代 晴実

- 出版者

- 日本学術会議 「機械工学委員会・土木工学・建築学委員会合同IUTAM分科会」

- 雑誌

- 理論応用力学講演会 講演論文集

- 巻号頁・発行日

- vol.57, pp.49, 2008

2007年7月の新潟県中越沖地震では、柏崎市にある自動車部品メーカーが被災したことにより、全国の日本の主要自動車メーカーが生産停止を余儀なくされた。地震時の企業のBCP(事業継続計画)を考える上では、サプライチェーンに依存した操業形態を有する企業の定量的なリスク評価手法が必要である。本論文では、サプライチェーンを構成する複数箇所の事業所の立地と、それぞれの地点での被害リスクを組み合わせ、企業の業務停止期間を定量的なリスク評価手法を提案する。これは、企業にとって、顧客への財・サービス提供の中断が長期化すれば、顧客の離反を招き、仮に長期間の休業後業務再開をしても、市場復帰が困難となるということに着目している。本論文では、直列型、並列型、併用型の3タイプのサプライチェーンが、東京23区、関東地方、東京300km圏の3つのスケールに生産拠点を展開した場合に、各地点の地震リスクとそれによる各拠点の業務停止期間のリスクカーブをもとに、サプライチェーン全体の業務停止期間を定量的に把握する手法を提案し、その有効性を検証した。

1 0 0 0 OA 野菜トラップによるスクミリンゴガイの捕獲効率の向上

- 著者

- 国本 佳範 西川 学

- 出版者

- 日本農作業学会

- 雑誌

- 農作業研究 (ISSN:03891763)

- 巻号頁・発行日

- vol.43, no.2, pp.75-82, 2008-06-25 (Released:2009-03-31)

- 参考文献数

- 11

スクミリンゴガイの水田に入っての拾い取りによる捕獲と,水田内に設置した野菜トラップによる捕獲および水田周囲に設置した野菜トラップによる捕獲について,作業時間,捕獲効率を比較した.貝が少なかった水田を除き,拾い取りによる捕獲の作業時間は,10a当たり2時間以上を要し,最も捕獲量の多かった水田では約536分を要した.しかし,1回の拾い取りでの捕獲効率は全捕獲の68.3%に止まり,稚苗移植水稲での要防除水準まで貝密度を減少させるには複数回の拾い取りが必要であった.これに対し,水田内に設置した野菜トラップでは4回のトラップでの捕獲を行うことで要防除水準以下の密度まで貝を減少させることができ,10a当たりの作業時間は約418分だった.水田周囲に設置した野菜トラップでは小規模な水田では13回のトラップによる捕獲で,要防除水準以下の密度にまで貝を減少させることができた.10a当たりに換算した作業時間は約116分で,この方法により短時間で簡単に貝を捕獲できることが示唆された.

1 0 0 0 魚群探知機とバーチャル生簀の融合による養殖魚計測技術の開発

- 著者

- 西川 悠

- 出版者

- 国立研究開発法人海洋研究開発機構

- 雑誌

- 戦略的な研究開発の推進 戦略的創造研究推進事業 さきがけ

- 巻号頁・発行日

- 2018

魚群探知機は海面下の魚の存在を探知するために漁業・養殖業・海洋調査などで広く使われていますが、魚群の全体像や個々の魚の特徴を捉えることは得意ではありません。本研究では、養殖生簀中の魚の成長や動きをシミュレートし、生簀に設置した魚群探知機のエコー画像と比較することで、生簀中の魚の体重分布・個体数計測の高精度化を目指し、魚群探知機から魚群の詳細な状態を知る技術の開発に挑みます。

1 0 0 0 OA 高麗時代の「叛逆伝」研究Ⅲ ―立伝人物の分析―

- 著者

- 西川 孝雄

- 出版者

- 愛知学院大学人間文化研究所

- 雑誌

- 人間文化 : 愛知学院大学人間文化研究所紀要 = Transactions of the Institute for Cultural Studies, Aichi Gakuin University NINGEN BUNKA (ISSN:09108424)

- 巻号頁・発行日

- no.22, pp.342-315, 2007-09-20

- 著者

- 丸山 愛美 井上 友希子 田島 悠来 杉本 かな恵 廣川 絢乙 山田 絵梨 橋本 南美 村川 弘樹 余田 智恵美 高山 南知 西川 開 中山 実咲 久野 智香 関岡 史織 可知 朋子 林 佑香 長尾 理菜 濱口 美果 水田 慎太郎 笹井 梨衣 森 仁樹 木村 眞実 川口 環 小南 理恵 西川 奈緒 吉井 嘉奈子 吉田 幸恵 有山 尚利 南 彩夏 中西 彩菜 辻野 夏奈子 吉野 瑞恵 山本 弥生 西口 真梨奈 高比良 南美 田上 一輝 工藤 未越 寺本 梨紗 鈴木 菜月

- 出版者

- 同志社大学図書館司書課程

- 雑誌

- 同志社大学図書館学年報 = Doshisha Library Science Annual (ISSN:09168850)

- 巻号頁・発行日

- no.39, pp.90-152, 2014-03-31

1 0 0 0 OA 脳梗塞予防のための水分摂取のリスクベネフィット-至適量提言のためのコホート研究

脳梗塞既往者314名のデータベースを作成し、これと並行して行っている健常者集団の調査(「日常的な健康度を指標とした都市コホート研究」(神戸トライアル)参加者の内、比較対象となる1013名)のデータと比較した。その飲水習慣から脳梗塞既往者の脳梗塞発症前の水分摂取量は健常者集団と比較して少ないことが推測された。この成果を国内外の学会にて発表を行い、まとめたものは国際英文雑誌であるCerebrovascular Diseasesに掲載された。

1 0 0 0 OA 平川浩正教授を悼む

- 著者

- 西川 哲治

- 出版者

- 一般社団法人 日本物理学会

- 雑誌

- 日本物理学会誌 (ISSN:00290181)

- 巻号頁・発行日

- vol.42, no.3, pp.286-287, 1987-03-05 (Released:2020-04-16)

1 0 0 0 最近の性能向上型排ガスエコノマイザプラント

- 著者

- 西川 栄一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.21, no.5, pp.330-337, 1986

The exhaust gas economizer is one of the most efficient measures for the exhaust heat recovery of the Diesel ship. In responding the strong demand of the fuel conservation, various advanced plants with turbo-generating system have been developed and have been successfully installed onto the Diesel ships in service. In spite of the difficulties of the decreasing gas temperature, the decreasing gas flow rate, the severe deterioration of fuel grade, etc., those newly developed plants have achieved the remarkable improvement of the exhaust heat recovery rate in comparison with the plants in the age of 1969. The main technological features of the advanced plants are the followings, that is, the first is the introduction of two-or three-stage pressure system, the second is the use of extended heating surface, and the third is the designs of various countermeasures against the low temperature fouling and corrosion. These features, however, have brought not only desirable improvements but also undesirable impacts such as the damage of generating tubes, the soot fire etc. Although most of impacts have already been overcomed, the soot fire, which is the most impressive and serious fault, is still troubling the people concerned and is demanding the reliable solution.

1 0 0 0 1.第3世代排ガスエコノマイザプラントと外部汚れ

- 著者

- 西川 栄一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.23, no.9, pp.594-599, 1988